Reinforced plastic composite coiled tubing coiling performance detection testing machine and detection method

A technology of reinforced plastics and coiled tubes, applied in the directions of strength characteristics, measuring devices, analytical materials, etc., can solve the problem of no special testing equipment, etc., and achieve the effect of saving test costs, saving laboratory space, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

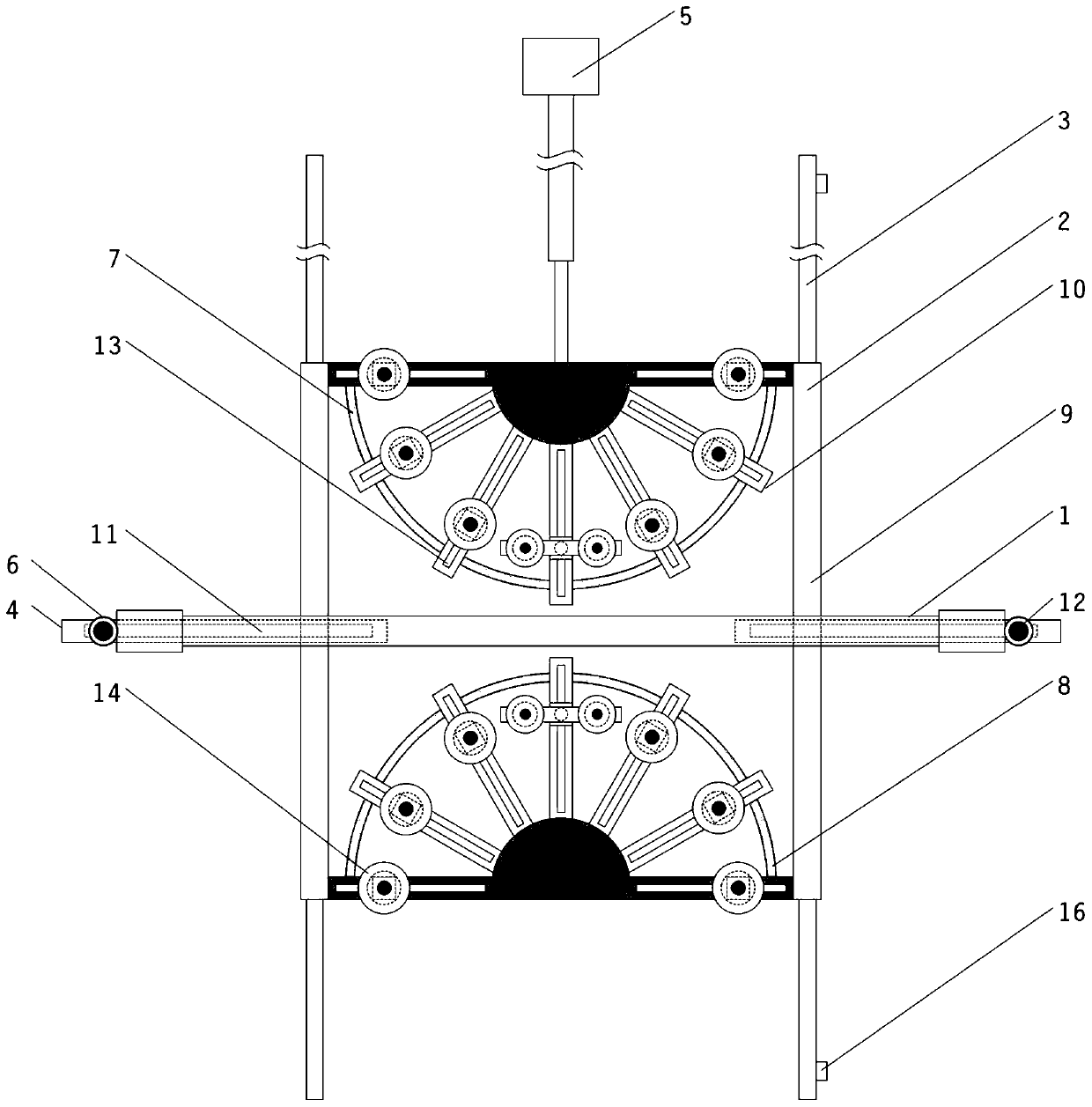

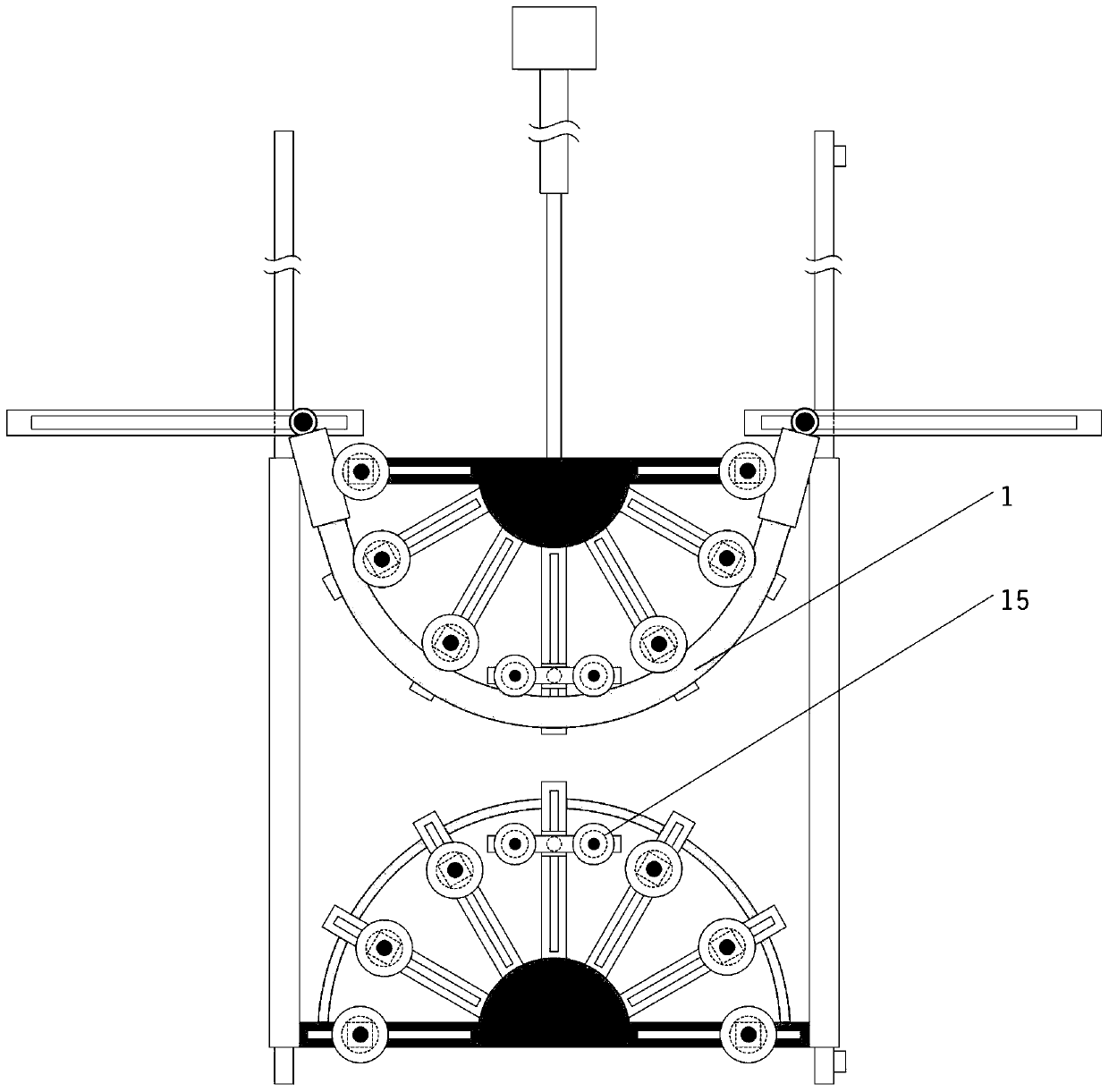

[0043] The coil performance test is carried out with polyester fiber reinforced polyethylene plastic composite continuous pipe with a specification of DN90mm and PN16MPa to determine the minimum coil size.

[0044] Step 1, adjust the position of all the rollers 14 in the first coiling device 7, so that the distance L between all the rollers 14 and the center of the circle of the first coiling device 7 after adjustment 1 Equal, L 1 =1500mm, and fixed roller 14.

[0045] Step 2, adjust the position of all the rollers 14 in the second coiling device 8, so that the distance L between all the rollers 14 and the center of the circle of the second coiling device 8 after adjustment 2 equal, and L 2 =L 1 =1500mm, and fixed roller 14.

[0046] Step 3, fix the two ends of a DN90mm PN16MPa polyester fiber reinforced polyethylene plastic composite continuous pipe sample 1 through the fixing ring 6 and the moving slider on the sample joint guide rail 4, and determine the coil size of th...

Embodiment 2

[0052] Aramid fiber reinforced cross-linked polyethylene downhole flexible composite coiled tubing with a specification of DN50mm and PN25MPa was used to conduct a coil performance test to verify whether the minimum coil size is 1200mm.

[0053] Step 1, adjust the position of all the rollers 14 in the first coiling device 7, so that the distance L between all the rollers 14 and the center of the circle of the first coiling device 7 after adjustment 1 Equal, L 1 =600mm, and fixed roller 14.

[0054] Step 2, adjust the position of all the rollers 14 in the second coiling device 8, so that the distance L between all the rollers 14 and the center of the circle of the second coiling device 8 after adjustment 2 equal, and L 2 =L 1 =600mm, and fixed roller 14.

[0055] Step 3, fix the two ends of an aramid fiber-reinforced cross-linked polyethylene downhole flexible composite continuous pipe sample 1 with a specification of DN50mm PN25MPa through the fixed ring 6 and the moving s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com