Motor train unit oil pipeline cooling unit

A technology of cooling unit and oil pipeline, which is applied in the direction of tubular components, damage protection, lighting and heating equipment, etc. It can solve the problems of not being able to meet the requirements of large-scale and rapid production, and achieve the convenience of rapid mass production, increase stability, and reduce connection difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

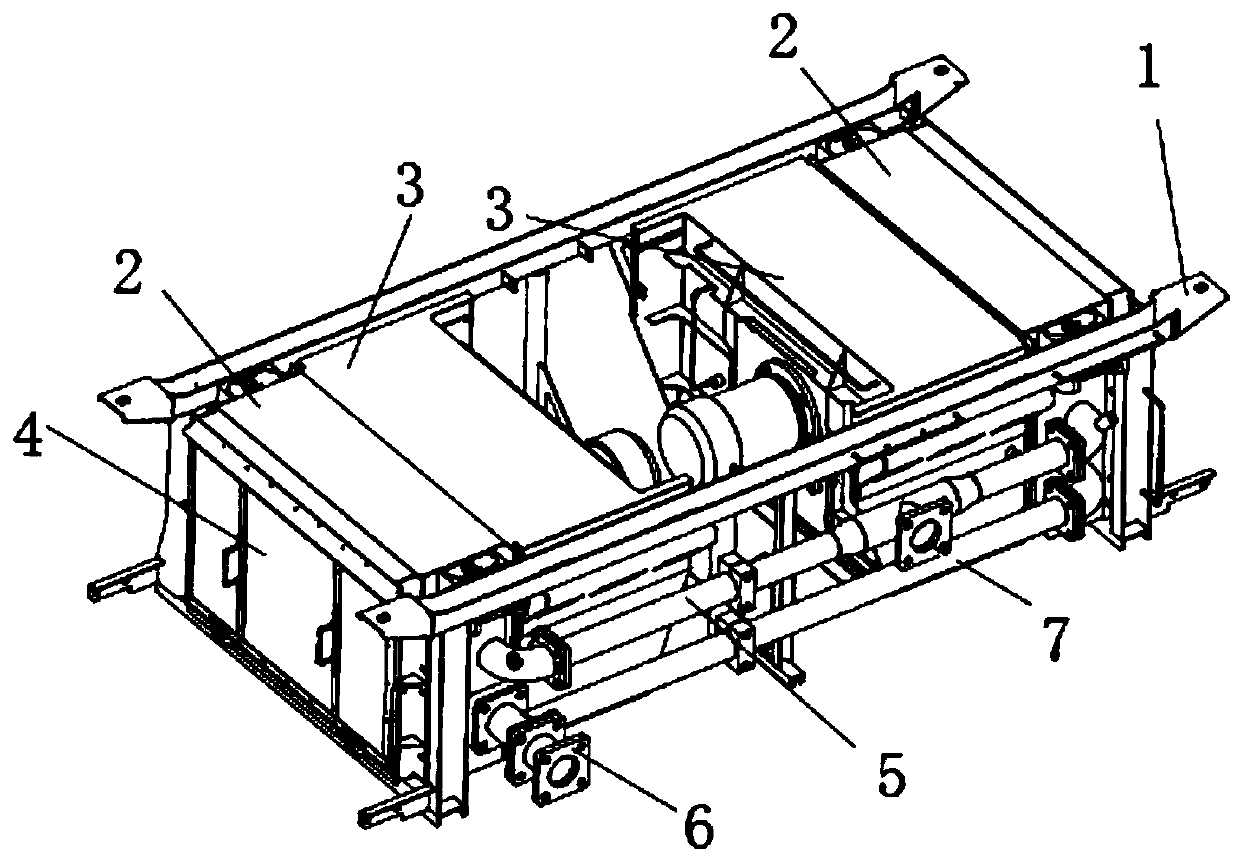

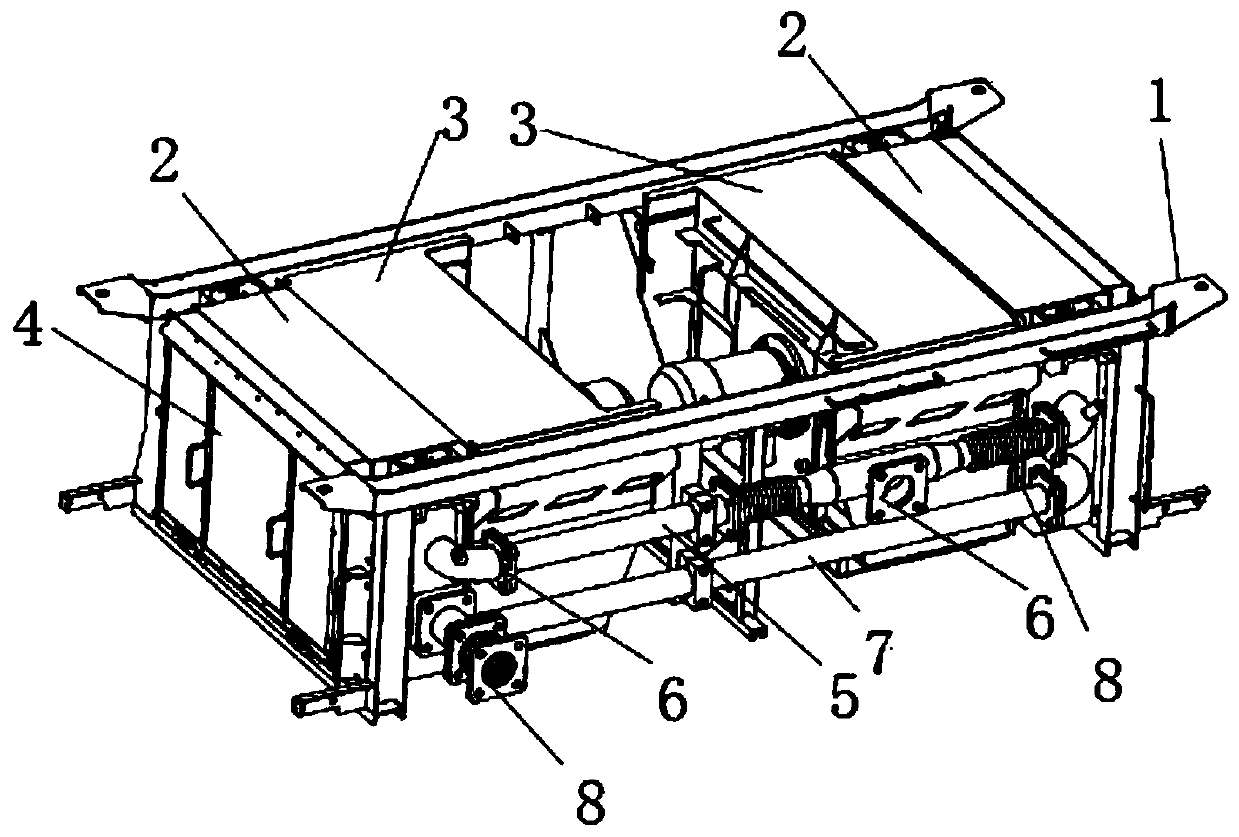

[0023] The specific implementation of the EMU oil pipeline cooling unit of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] See attached figure 2 , EMU oil pipe 7 road cooling unit includes oil pipe 5, radiator 2 and fan unit 3, oil pipe 5 is cooled by radiator 2 and fan unit 3, oil pipe 5 includes oil pipe 7 and pipe fitting 6, pipe fitting 6 is connected to oil pipe 7 Multiple positions are connected by setting expansion joints 8 at multiple connections between the pipe fitting 6 and the oil pipe 7 .

[0025] The expansion joint 8 is made of metal material, and a bellows expansion joint can be selected. For the different conditions of the installation location, various accessories such as pipe joints can be provided for connection, and the structure of the expansion joint 8 is a conventional or special-shaped structure, which does not affect the technical solution of the present invention.

[0026] The EMU oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com