Dehydration device for dried chicken floss processing by using bamboo tube

A technology of dehydration device and chicken floss, which is applied in the direction of heating device, lighting and heating equipment, drying machine for static materials, etc. It can solve the problems of poor dehydration effect affecting the quality of chicken floss products, so as to ensure uniform dehydration effect and increase shaking intensity and effect, the effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

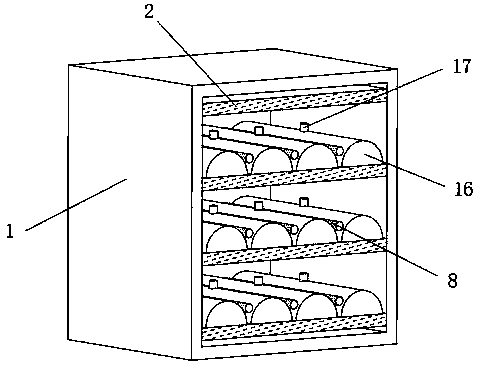

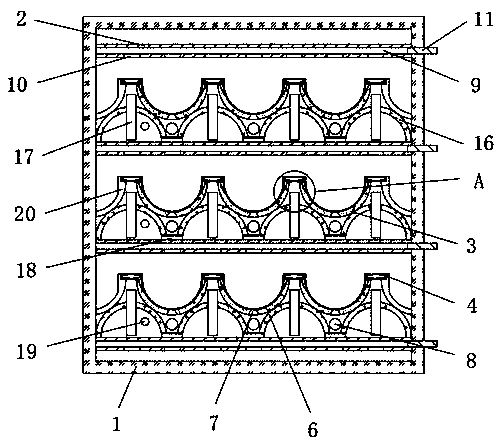

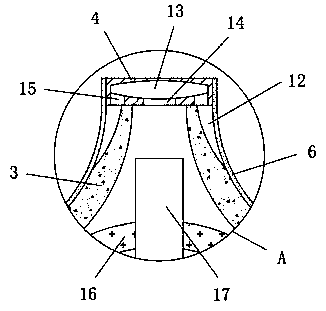

[0026] refer to Figure 1-4 , a dehydration device for processing chicken floss using bamboo tubes, comprising a baking oven 1, a plurality of partition seats 2 are fixed between the inner walls on both sides of the oven 1, and the interior of the oven 1 is composed of multiple partition seats 2 A baking cavity, a heating element 8 and a steam guide pipe 11 are fixed in the baking cavity, a placing seat is placed at the bottom of the baking cavity, and the top of the placing seat is covered with chicken material, and the placing seat is provided with a plurality of semicircular sections. shaped bamboo tube plate 3, and the inner wall of the bamboo tube plate 3 is provided with a plurality of arc-shaped spacer bars 5, the bamboo tube plate 3 and the spacer bar 5 are integrally formed structures, and mesh cloth 6 is fixed between the inner walls of the two sides of the bamboo tube plate 3 , and the bottom of the mesh cloth 6 naturally hangs down to fit the inner wall of the bamb...

Embodiment 2

[0035] refer to Figure 1-4 , a kind of dehydration device that utilizes bamboo tube to carry out chicken floss processing, on the basis of embodiment 1, bamboo tube plate 3 is arranged to adopt feed liquid cooking, before using bamboo tube plate 3, bamboo tube plate 3 is placed in feed liquid to cook, The bamboo tube plate 3 made of bamboo is used to dissolve part of the feed liquid, and evaporates to various positions of the bamboo tube plate 3 during the baking and dehydration process, further enhancing the taste and quality of the actual chicken floss production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com