A freeze-thaw system for freezing, thawing or mixing processes of biopharmaceutical materials

A biopharmaceutical material and mixing process technology, applied in the field of freeze-thaw system, can solve the problems of out-of-sync temperature treatment, no temperature record, low production efficiency, etc., and achieve the effect of beautiful molding, easy cleaning and disinfection, and uniformity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

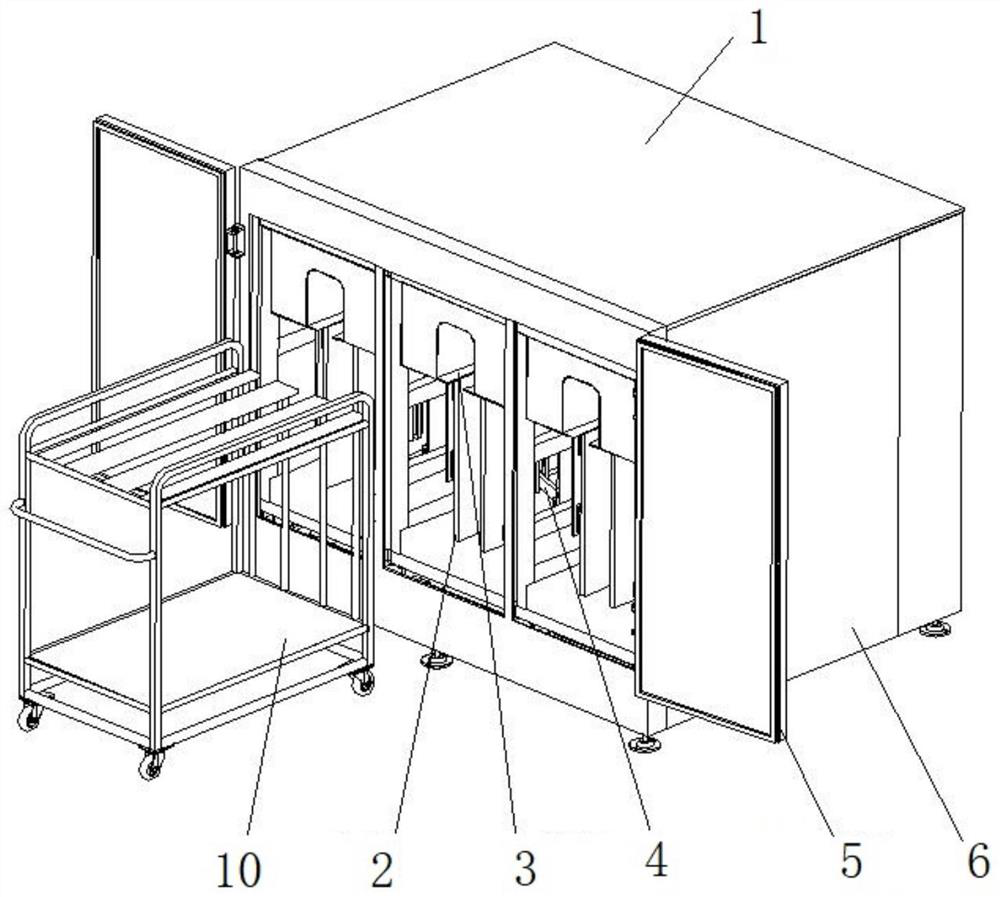

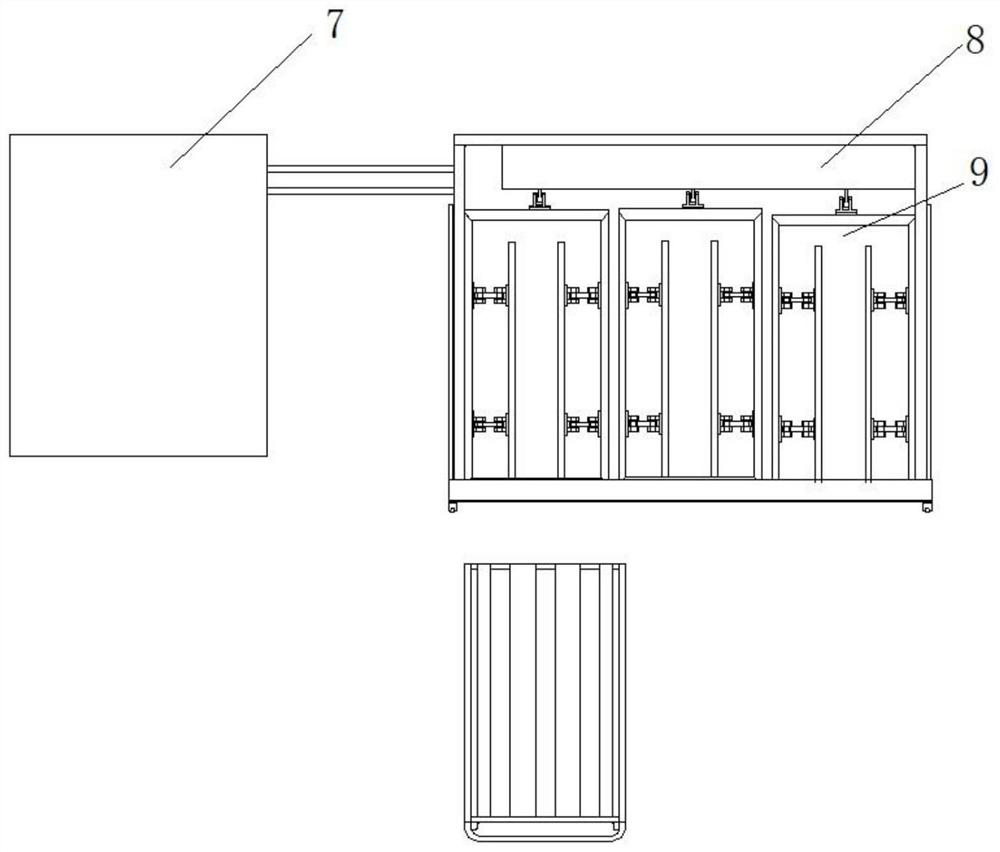

[0022] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

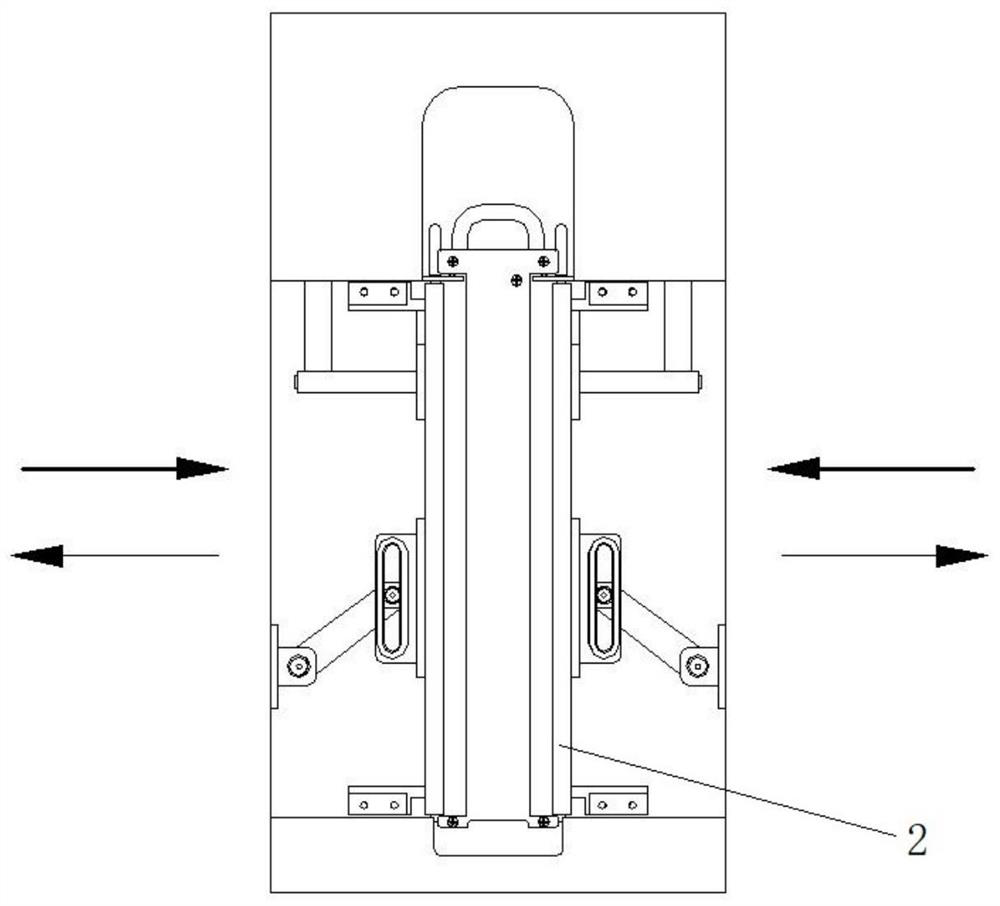

[0023] Such as Figure 1-4 As shown, the present invention provides a freeze-thaw system for freezing, thawing or mixing process of biopharmaceutical materials, including a freeze-thaw machine 1, a cooling and heating unit 7, a compartment 9, a partition 2, a driving mechanism 4 and a rocking mechanism 8. The freeze-thaw machine 1 is provided with a cabin 9; the cabin 9 is provided with two corresponding parallel partitions 2, a drive mechanism 4 and a swing mechanism 8 whose board surfaces are vertical to the ground; the partition 2 is set as a hollow plate shape, the interior of the partition is provided with a temperature-conducting medium, and the partition 2 is connected to the cooling and heating unit 7; the board surfaces of the two partitions 2 move towards each other and separate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com