Integrated heat supply component

An integrated and component-based technology, applied in the field of vehicle parts, can solve problems such as poor heat dissipation of the engine cylinder head, poor reliability of multiple pipelines, damage to the engine cylinder head, etc., and achieve the effects of good appearance, improved stability, and reduced circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

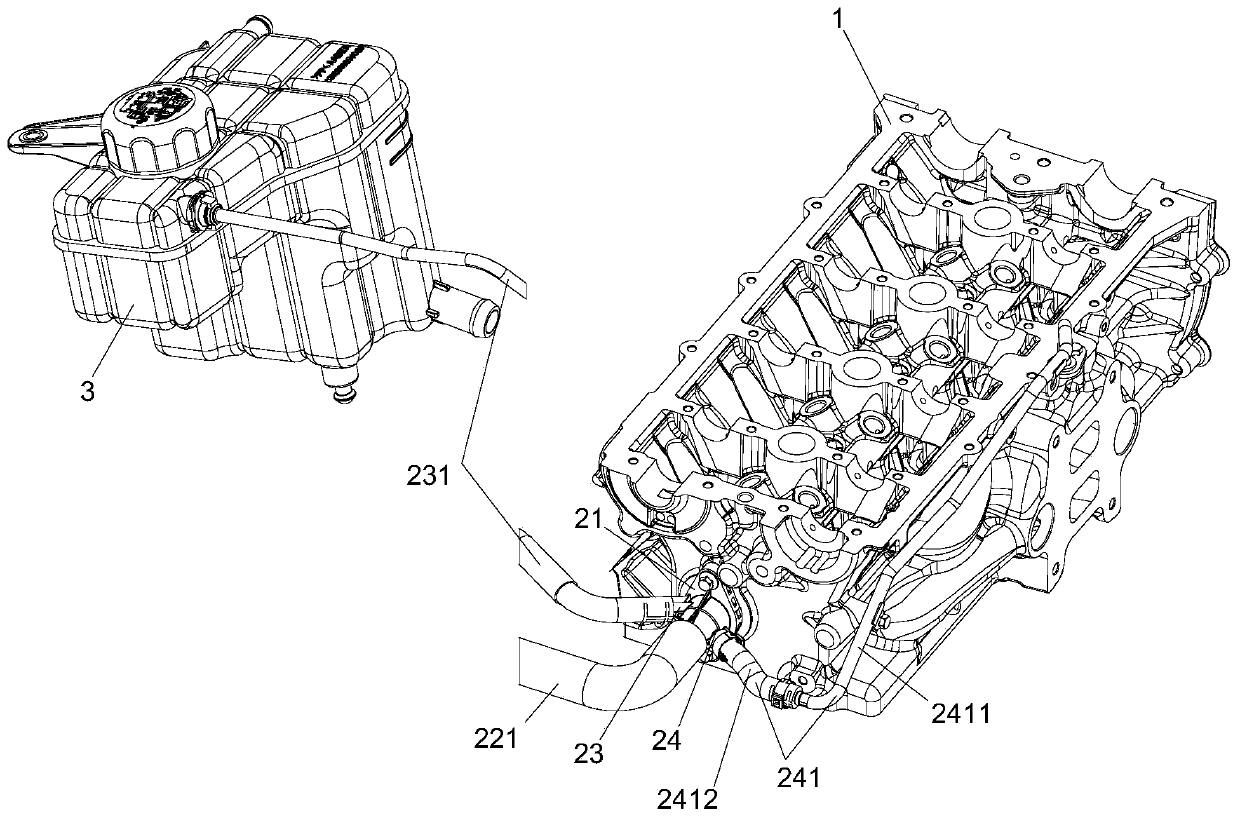

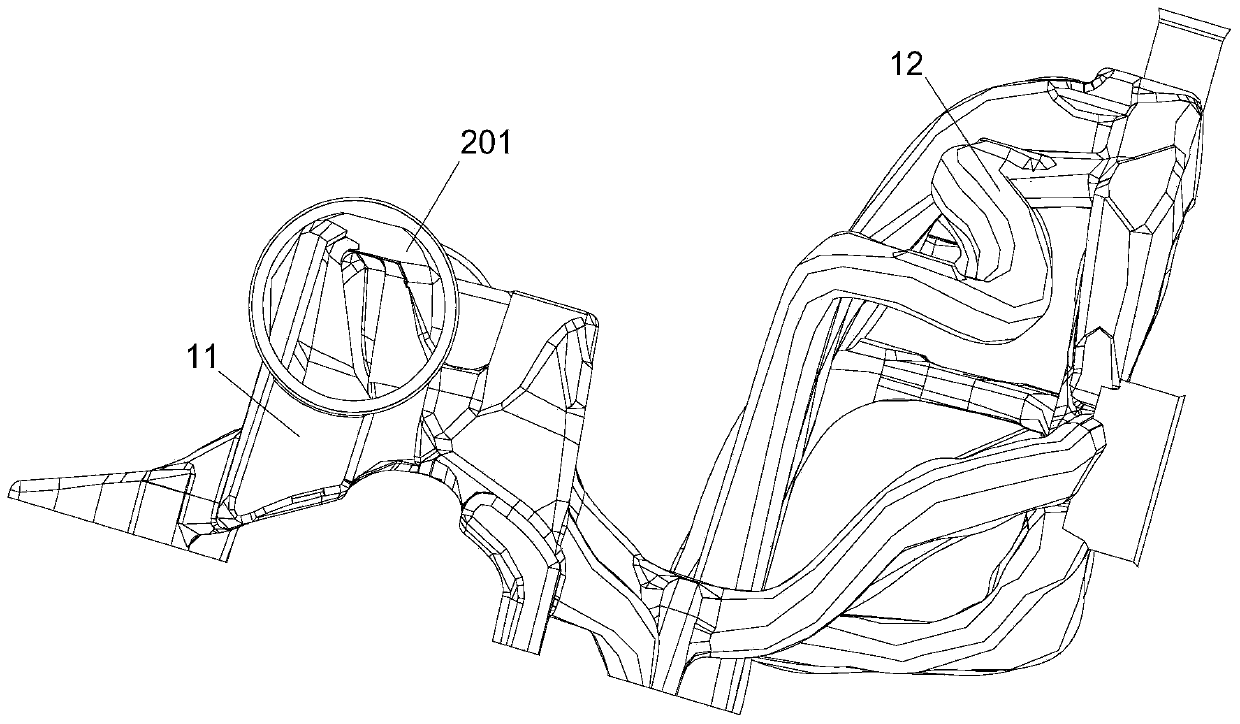

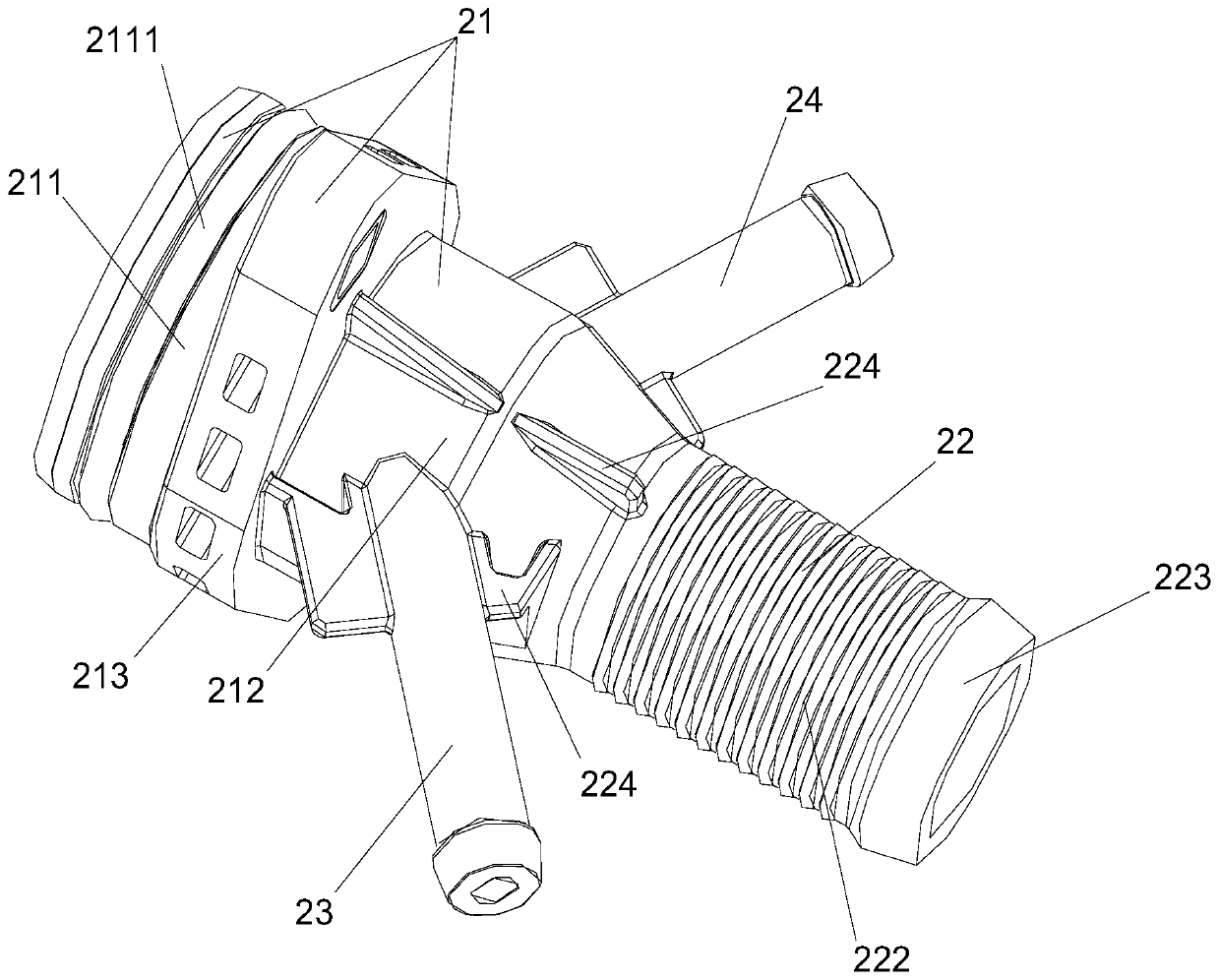

[0037] This embodiment relates to an integrated heating component, which is fixed on the engine cylinder head 1, and the engine cylinder head 1 is configured with a body water jacket 11 for cooling the engine cylinder head 1 body 21. like Figure 1 to Figure 5 As shown, the integrated heating component includes a body 21, and a cavity 201 communicated with the highest point of the body water jacket 11 is configured on the body 21. In addition, the integrated heating component also includes a cavity 201 arranged on the body 21. The heat supply part 22 connected to the cavity 201 and the heat exchange device arranged on the vehicle, and the exhaust part 23 arranged on the main body 21, the exhaust part 23 can constitute the cavity 201 and the heat exchange device arranged on the vehicle. The communication of the gas guiding device that can discharge the gas to the outside.

[0038] In terms of specific structure, such as image 3 and Figure 4 As shown, the body 21 includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com