Nano bamboo charcoal chopsticks and preparation method thereof

A technology of nano-bamboo charcoal and chopsticks, which is applied in the field of plastic chopsticks, can solve the problems of complex production process, limit the popularization and application of nano-bamboo charcoal chopsticks, and high raw material cost of silver-loaded zinc-copper zeolite, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

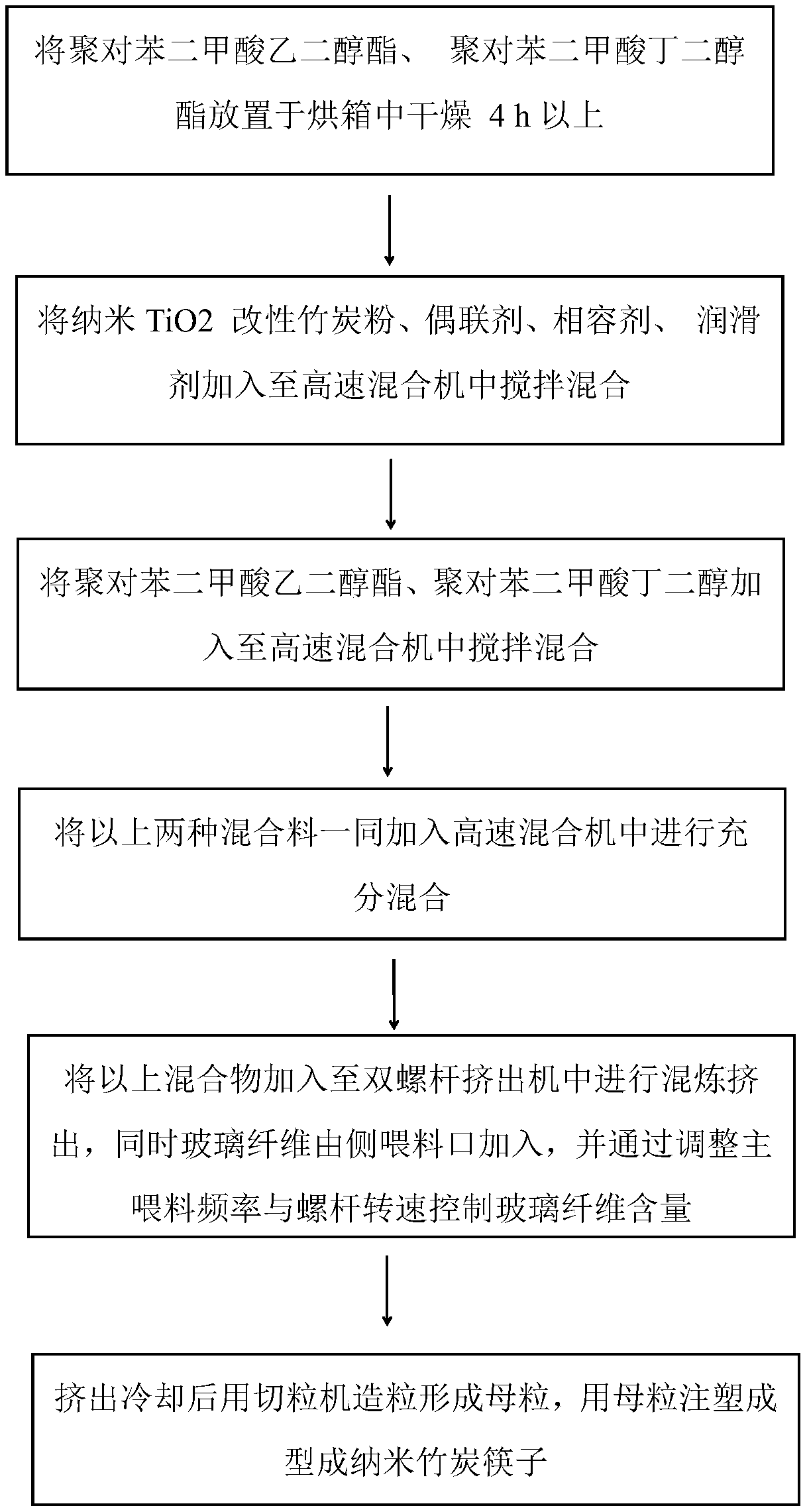

Image

Examples

Embodiment 1

[0023] Raw material preparation:

[0024] Place polyethylene terephthalate and polybutylene terephthalate in an oven at 120°C to dry for more than 4 hours; the diameter of nano-TiO2 modified bamboo charcoal powder is 13 nanometers; the glass fiber is alkali-free glass fiber , with a diameter of 10 μm.

[0025] Weigh raw materials:

[0026] Weigh 20 parts of nano-TiO2 modified bamboo charcoal powder, 0.2 parts of silane coupling agent, 0.2 parts of titanate coupling agent, 1.6 parts of maleic anhydride grafted ethylene-octene copolymer, 2 parts of internal lubricant, polyparaphenylene 40 parts of ethylene glycol diformate (PET), 20 parts of polybutylene terephthalate (PBT).

[0027] Raw material mix:

[0028] Add the weighed nano-TiO2 modified bamboo charcoal powder, silane coupling agent, titanate coupling agent, maleic anhydride grafted ethylene-octene copolymer and internal lubricant into a high-speed mixer and stir and mix; Take the good polyethylene terephthalate and p...

Embodiment 2

[0042] Raw material preparation:

[0043] Place polyethylene terephthalate and polybutylene terephthalate in an oven at 120°C to dry for more than 4 hours; the diameter of nano-TiO2 modified bamboo charcoal powder is 13 nanometers; the glass fiber is alkali-free glass fiber , with a diameter of 10 μm.

[0044] Weigh raw materials:

[0045] Weigh 10 parts of nano-TiO2 modified bamboo charcoal powder, 0.2 parts of silane coupling agent, 0.1 part of titanate coupling agent, 1.7 parts of maleic anhydride grafted ethylene-octene copolymer, 3 parts of internal lubricant, polyparaphenylene 40 parts of ethylene glycol diformate (PET), 30 parts of polybutylene terephthalate (PBT);

[0046] Raw material mix:

[0047] Add the weighed nano-TiO2 modified bamboo charcoal powder, silane coupling agent, titanate coupling agent, maleic anhydride grafted ethylene-octene copolymer and internal lubricant into a high-speed mixer and stir and mix; Take the good polyethylene terephthalate and po...

Embodiment 3

[0056] Raw material preparation:

[0057] Put polyethylene terephthalate and polybutylene terephthalate in an oven at 120°C for more than 4 hours; the diameter of nano-TiO2 modified bamboo charcoal powder is 20 nanometers; the glass fiber is alkali-free glass fiber , with a diameter of 13 μm.

[0058] Weigh the raw materials:

[0059] Weigh 15 parts of nano-TiO2 modified bamboo charcoal powder, 0.2 part of silane coupling agent, 0.1 part of titanate coupling agent, 1.7 parts of maleic anhydride grafted ethylene-octene copolymer, 3 parts of internal lubricant, polyparaphenylene 40 parts of ethylene dicarboxylate (PET) and 25 parts of polybutylene terephthalate (PBT);

[0060] Raw material mix:

[0061] The weighed nano-TiO Modified bamboo charcoal powder, silane coupling agent, titanate coupling agent, maleic anhydride grafted ethylene-octene copolymer and internal lubricant are added to the high-speed mixer and stirred and mixed; The obtained polyethylene terephthalate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com