A high-strength autonomous self-healing hydrogel based on dopamine and its preparation method

A hydrogel and dopamine technology, applied in the field of biomaterials, can solve problems such as reducing or even reducing acidity, gelation failure, and hindering acrylamide polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

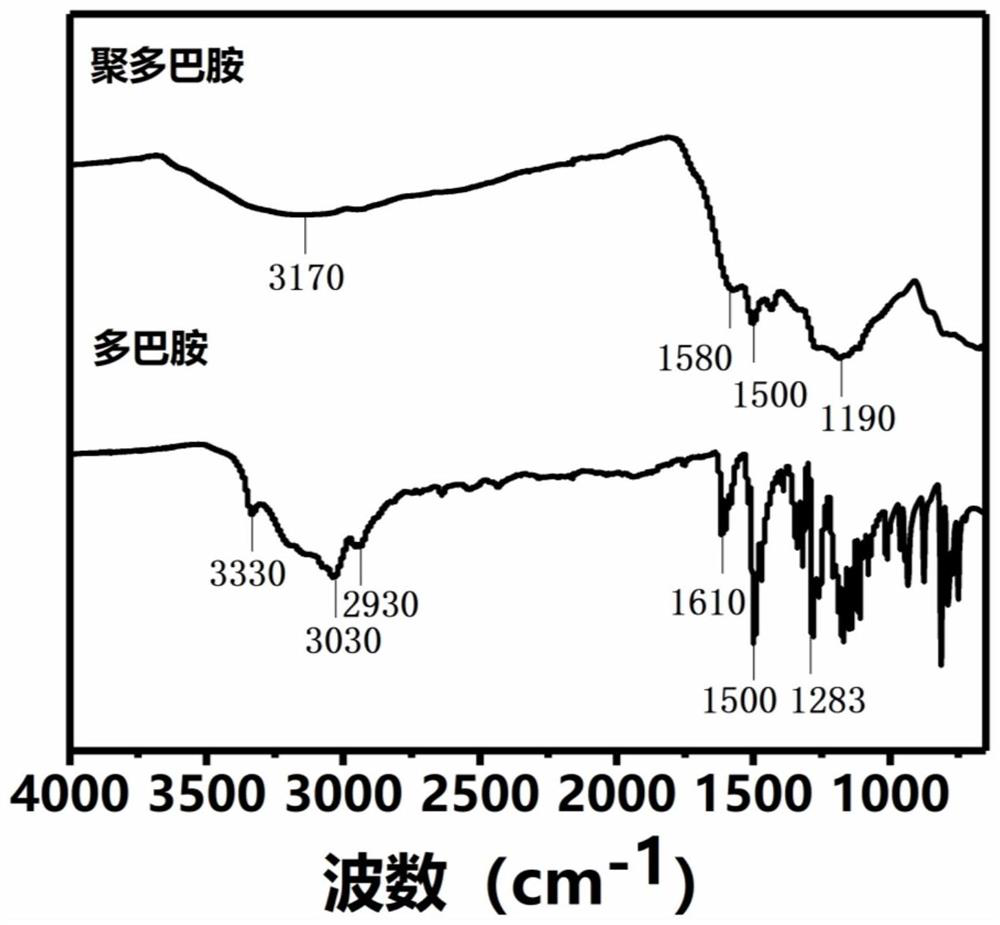

[0030]In the first step, 0.04 g of dopamine powder was dissolved in 22 mL of sodium hydroxide solution (pH=11) at room temperature, and stirred at pH 8-12 for 2 h to form a polydopamine solution.

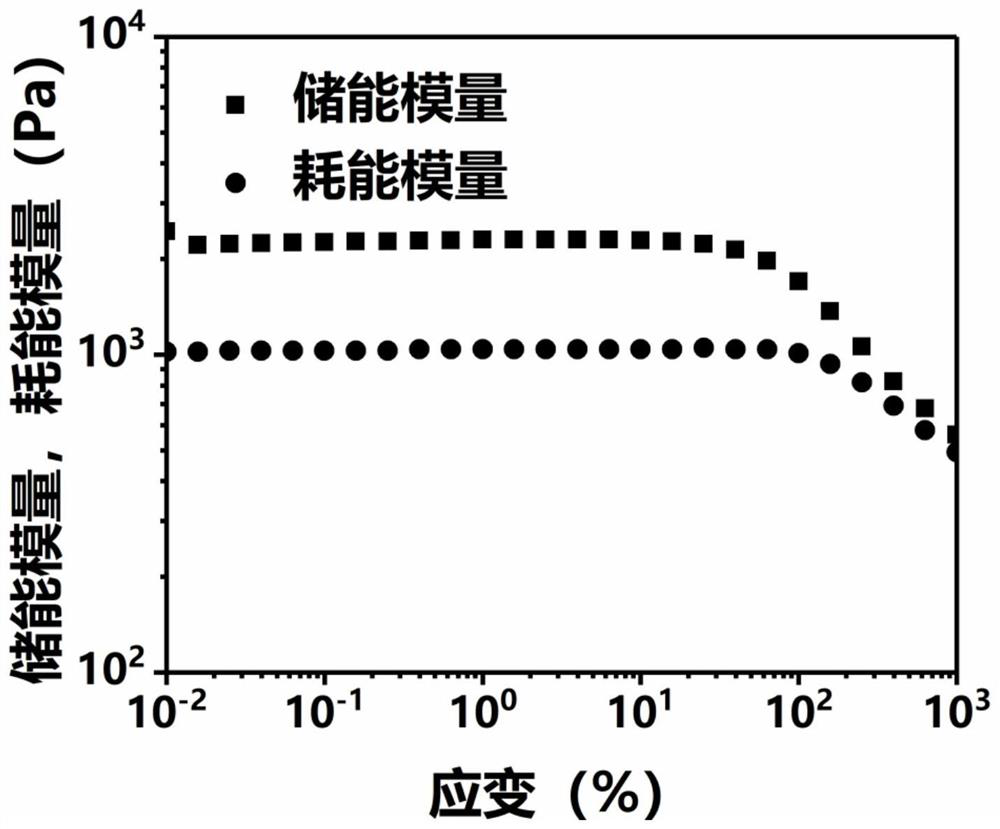

[0031] In the second step, at room temperature, mix 5g acrylamide, 8mg N,N'-methylenebisacrylamide and 0.4g ammonium persulfate in polydopamine solution, stir for 10 minutes, then add 60μL tetramethylethylenediamine , acrylamide polymerized within 1 min to form polydopamine-polyacrylamide hydrogel.

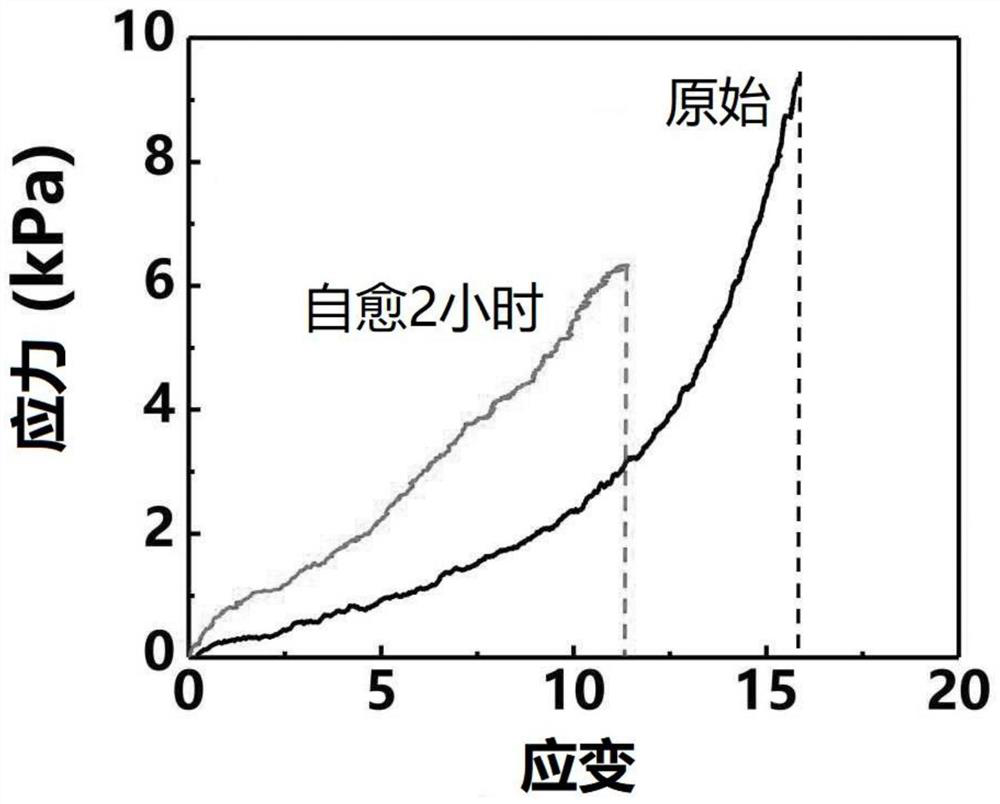

[0032] The static self-healing efficiency of the polydopamine-polyacrylamide (dopamine / acrylamide=0.8%) hydrogel obtained in Example 1 was quantitatively evaluated by stretch-repair-stretch test. The pristine gel showed tensile stresses as high as 9.4 kPa ( figure 1 ). In the absence of external stimuli, the repair balance can be reached within 2 hours. The tensile strength recovered to 67% of the intact hydrogel, and the final tensile elongation at break recovered to 70%.

Embodiment 2

[0034] Further, in order to prepare polydopamine-polyacrylamide hydrogel with high dopamine content (dopamine / acrylamide=1.6%), adjust the first step polydopamine preparation process in Example 1: adjust the solution pH and ammonium persulfate content to stimulate dopamine polymerization.

[0035] In the first step, 0.08 dopamine powder was dissolved in 22 mL of sodium hydroxide solution (pH=11) at room temperature, stirred for 1 h, then 0.2 g of ammonium persulfate was added to the solution, and stirred at pH 8-12 for 2 h, A polydopamine solution is formed.

[0036] In the second step, 5g of acrylamide, 3.5mg of N,N'-methylenebisacrylamide and 0.2g of ammonium persulfate were mixed in the polydopamine solution at room temperature. After stirring for 10 minutes, 40 μL of tetramethylethylenediamine was added, and acrylamide polymerized within 1 min to form a polydopamine-polyacrylamide hydrogel.

Embodiment 3

[0038] Further, in order to prepare polydopamine-polyacrylamide hydrogel with high dopamine content (dopamine / acrylamide=5%), adjust the first step polydopamine preparation process in Example 1: adjust the solution pH and ammonium persulfate content to stimulate dopamine polymerization.

[0039] In the first step, 0.25 g of dopamine powder was dissolved in 22 mL of sodium hydroxide solution (pH=11) at room temperature, stirred for 1 h, then 1 g of ammonium persulfate was added to the solution, and stirred at pH 8-12 for 2 h, A polydopamine solution is formed.

[0040] In the second step, 5g of acrylamide, 2.5mg of N,N'-methylenebisacrylamide and 0.2g of ammonium persulfate were mixed in the polydopamine solution at room temperature. After stirring for 10 minutes, 20 μL of tetramethylethylenediamine was added, and acrylamide polymerized within 1 min to form a polydopamine-polyacrylamide hydrogel.

[0041] The synthesis method of Example 3 successfully prepared polydopamine-po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com