A high-strength flame-retardant polyphenyl resin and its application in the preparation of thermal insulation boards

A polyphenyl resin, high-strength technology, applied to high-strength flame-retardant polyphenyl resin and its application in the preparation of thermal insulation boards, can solve the problems of weak load-bearing capacity, reduced flame retardant performance of thermal insulation boards, low strength and the like , to achieve the effect of improving strength and toughness, improving strength and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

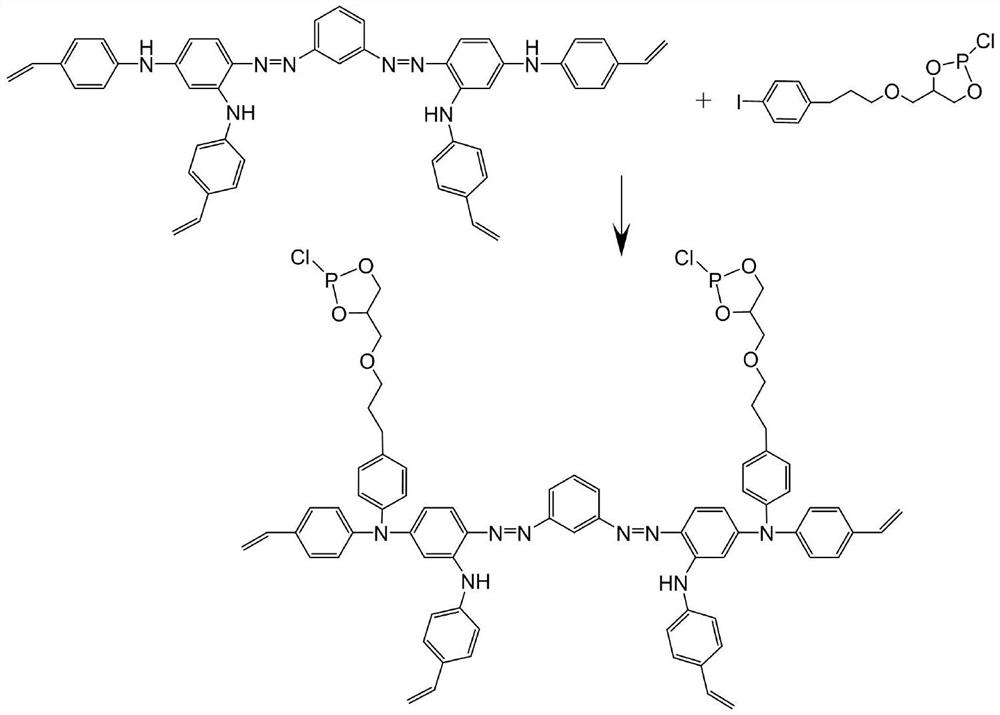

[0034] The specific preparation process of high-strength flame-retardant polyphenyl resin is as follows:

[0035] Step 1: α-allyl glyceryl ether and phosphorus oxychloride are added to the reaction tank at the same time according to the ratio of the amount of substances in the ratio of 1:1.16, wherein the tail end of the condenser tube provided in the reaction tank is passed into the sodium hydroxide The solution is used to absorb the generated hydrogen chloride gas, and the temperature is raised to 50°C for reflux reaction for 4 hours, and then the product is subjected to rotary evaporation to remove the unreacted phosphorus oxychloride in it to obtain allyl phosphoric acid, which is subjected to infrared IR analysis , at 543cm -1 The infrared absorption peak of the P-Cl bond appears at 1028cm -1 The infrared absorption peak of the P-O-C bond appeared at 3018cm -1 The stretching vibration peak of the C=C double bond appears at ;

[0036] Step 2: After continuously blowing ...

Embodiment 2

[0043] The concrete preparation process of polyphenyl resin is as follows:

[0044] Step 1: Weigh 1 mol of bismanii brown, add it to water and stir to dissolve, then add 4.35 mol of 4-vinylphenol and 9.4g of phosphoric acid to it, heat up to 220°C for reflux reaction for 5 hours, remove unreacted 4-vinylphenol under reduced pressure, After cooling, add sodium hydroxide solution with a mass concentration of 8%, stir until crystals are precipitated, then filter after standing overnight, wash with ethanol and dry to obtain unsaturated alkaline brown;

[0045] Step 2: Add 1 mol of unsaturated basic brown, 4.3 mol of iodobenzene, 6.8 g of copper powder, 0.12 mol of potassium carbonate and 3 L of nitrobenzene into the reaction tank at the same time, raise the temperature to 170°C for 24 hours under reflux, and then dissolve the product with dichloro Methane is extracted, followed by vacuum distillation to remove the solvent, and the obtained product is sequentially washed with water...

Embodiment 3

[0048] The specific preparation process of the high-strength flame-retardant polyphenyl resin is the same as in Example 1, and the Bismarck brown used in Example 1 is replaced by p-phenylenediamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com