High-quality-factor microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and high quality factor, applied in the field of microwave dielectric materials, can solve the problems of high sintering cost and high sintering temperature, and achieve the effect of low sintering cost, low sintering temperature and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

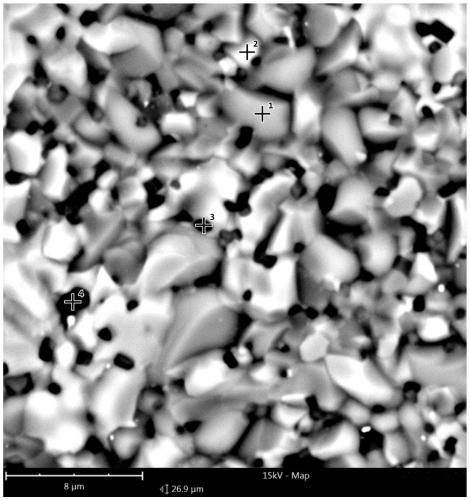

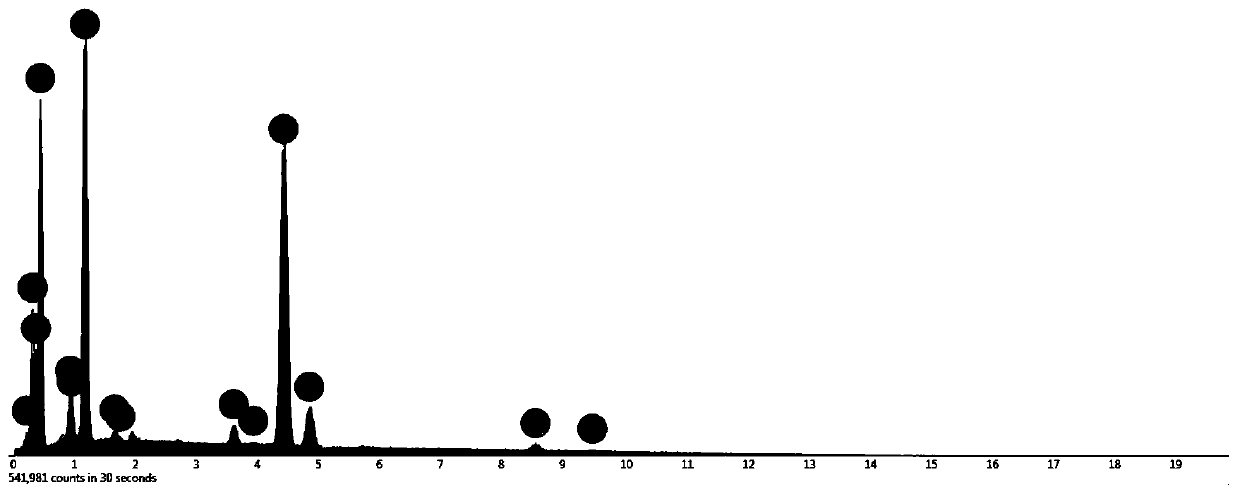

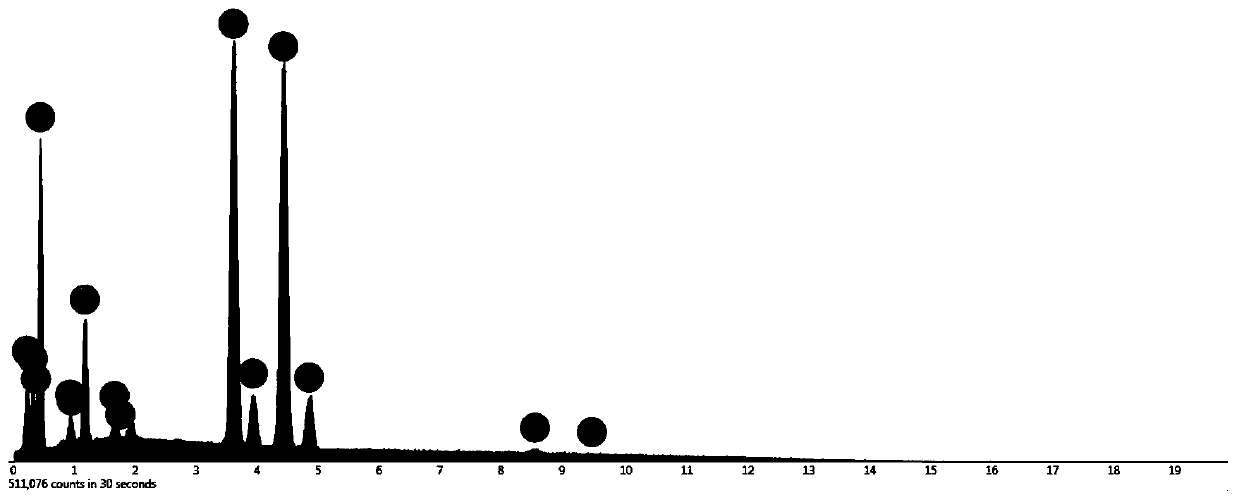

Image

Examples

Embodiment

[0030] The microwave dielectric ceramic material with high quality factor is prepared, specifically through the following method.

[0031] The microwave dielectric ceramic material is raw material according to the following formula expression: (1-x)(Mg 1-y ,Zn)TiO 3 +xCaTiO 3 +awt%Mg 2 SiO 4 +bwt%MO;

[0032] Wherein, 0.03≤x≤0.08, 0.05≤y≤0.3, 0≤a≤15, 0≤b≤3; said a and b are respectively said Mg 2 SiO 4 and MO accounted for (1-x)(Mg 1-y ,Zn)TiO 3 +xCaTiO 3 The mass percentage; MO is a metal oxide, preferably a metal oxide MnO 2 、Al 2 o 3 , CeO 2 and Nb 2 o 5 one or more of.

[0033] The specific operation of the preparation process is as follows:

[0034] Step 1, synthesis of Mg 2 SiO 4 ; will analyze pure MgCO 3 and SiO 2 According to Mg 2 SiO 4 The stoichiometric ratio is batched to form the first batch, and according to the first batch: deionized water: zirconia ball weight ratio is 1: (2 ~ 3): (3 ~ 4) ratio, in the horizontal ball mill Mixed in the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com