Auxiliary frame for vehicle, in particular electric vehicle

A technology for electric vehicles and sub-frames, which is used in the connection between motor vehicles, vehicle components, and superstructure sub-assemblies, etc., can solve the problems of low strength, increased chassis wear, and heavy weight, and achieve high bending strength and Rigidity, reduced mechanical stress, high rigidity and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

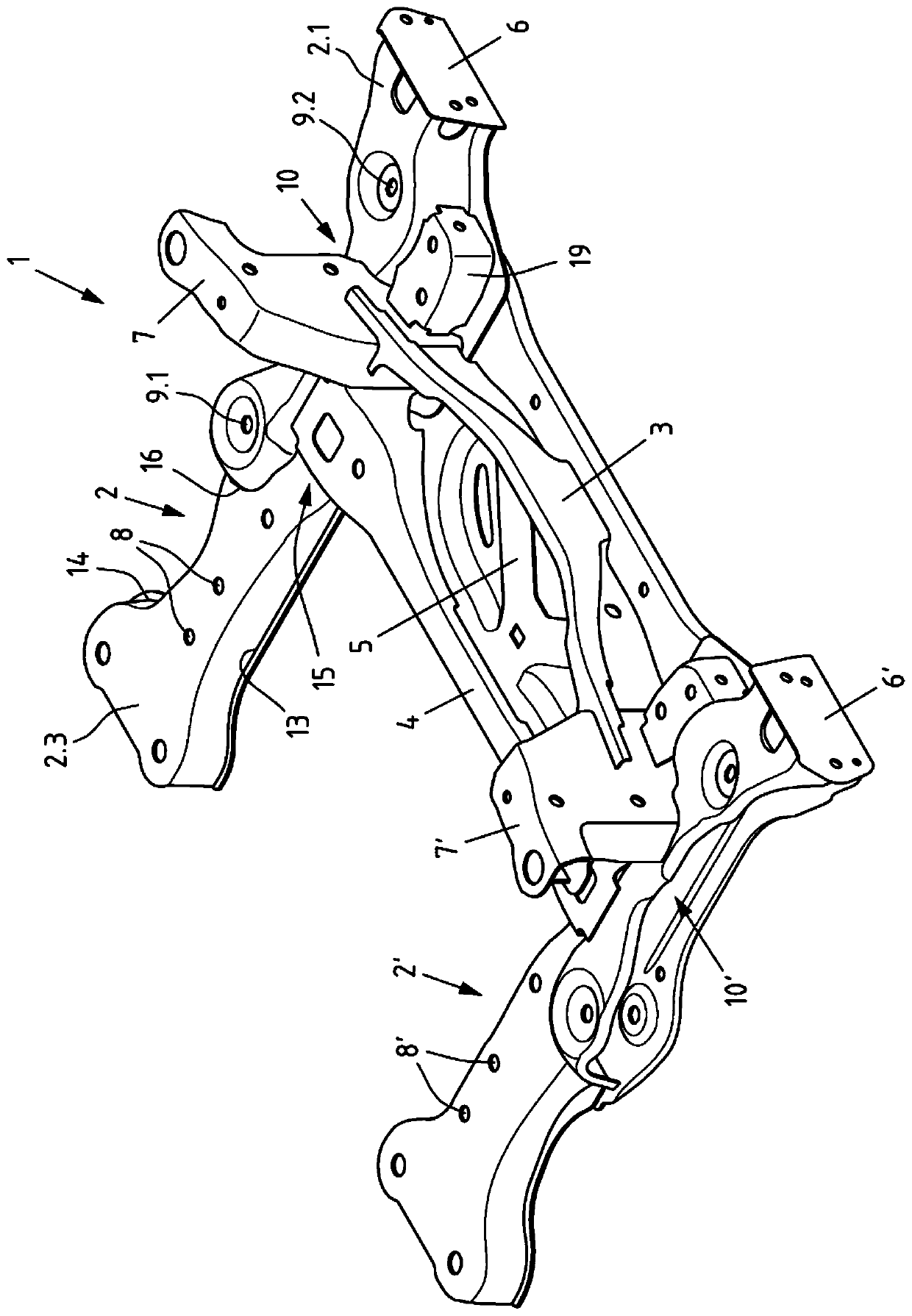

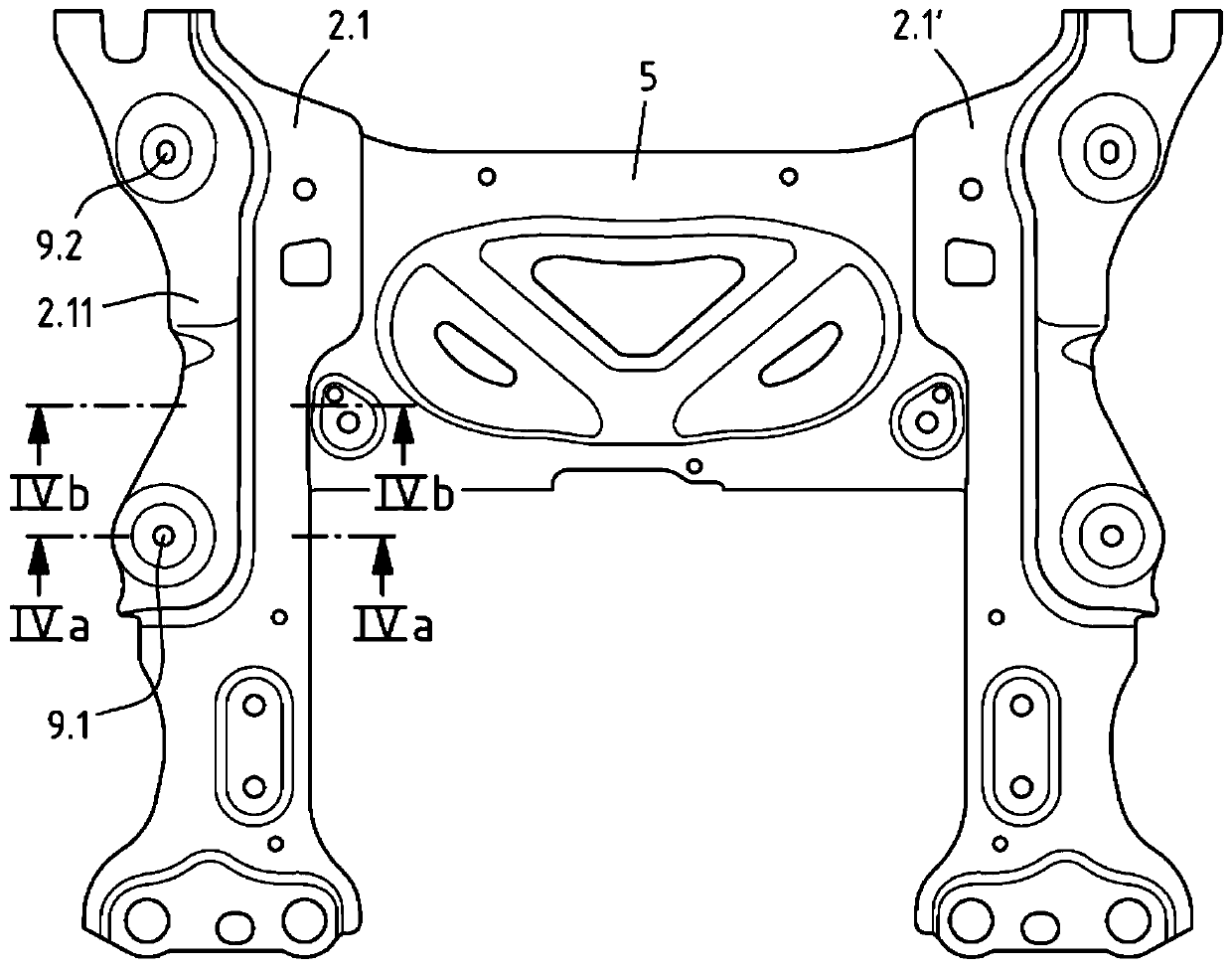

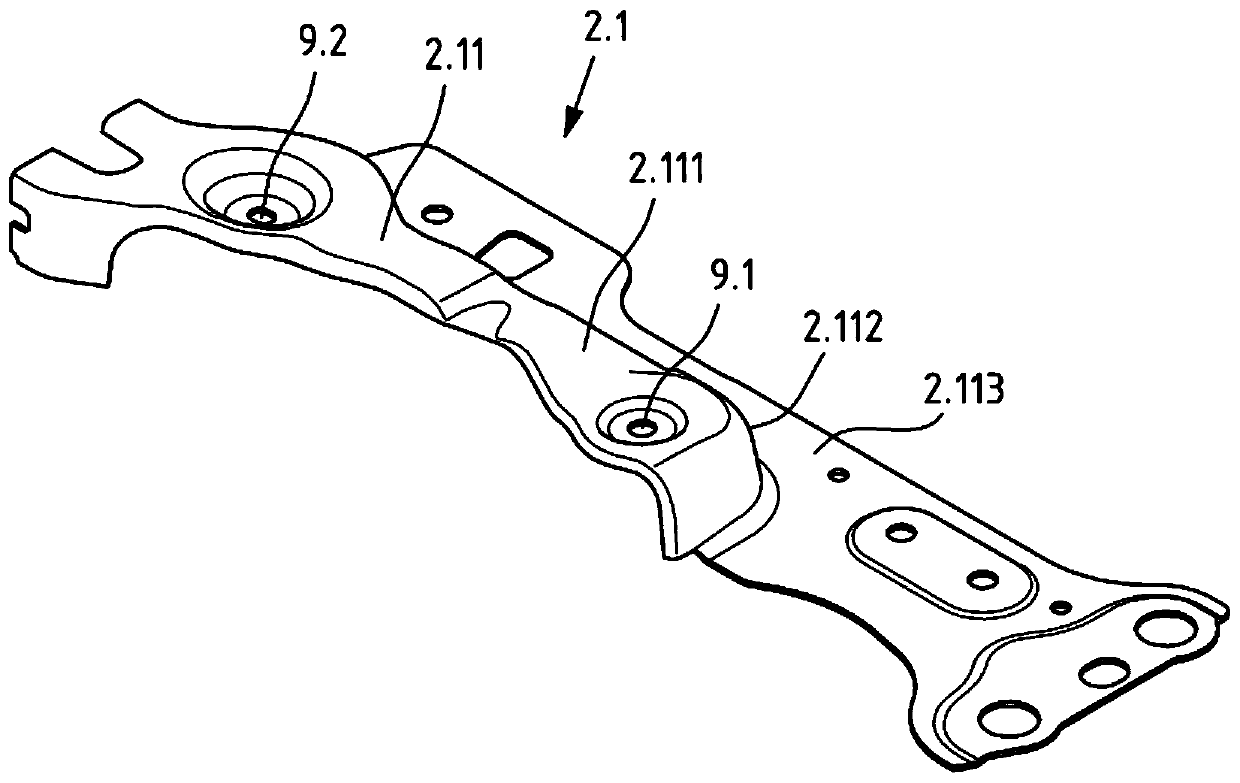

[0036] figure 1 A subframe 1 for a motor vehicle, in particular an electric vehicle, is shown. The subframe 1 , which is embodied here by way of example as a front axle subframe, is composed of a longitudinal frame and a transverse frame. The term “longitudinal frame” is understood here to mean a bearing element or a section of a bearing element of a subframe which, in the installed state of the subframe 1 , extends substantially along the longitudinal axis of the relevant motor vehicle. In contrast, the transverse support extends substantially transversely to the longitudinal axis of the motor vehicle in the installed state of the subframe 1 .

[0037] The longitudinal support and the transverse support are made of sheet metal (sheet metal shell). exist figure 1 Shown in particular is a left longitudinal support 2, a right longitudinal support 2', a front transverse support 3 and an upper shell 4 serving as a transverse support. Also visible are sheet metal shells 5 servi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com