Heat-sensitive photocatalytic spray gel and preparation method thereof

A heat-sensitive, photocatalytic technology, applied in the field of air purification, can solve the problems of weak PM2.5 purification, difficult to completely remove, secondary environmental pollution, etc., achieve high-efficiency photocatalytic purification performance, not easy to crystallization fragmentation and falling off, The effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

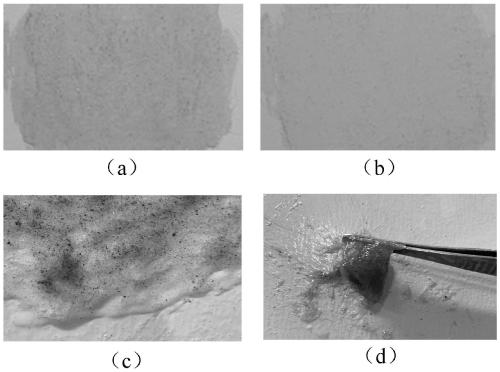

Image

Examples

Embodiment 1

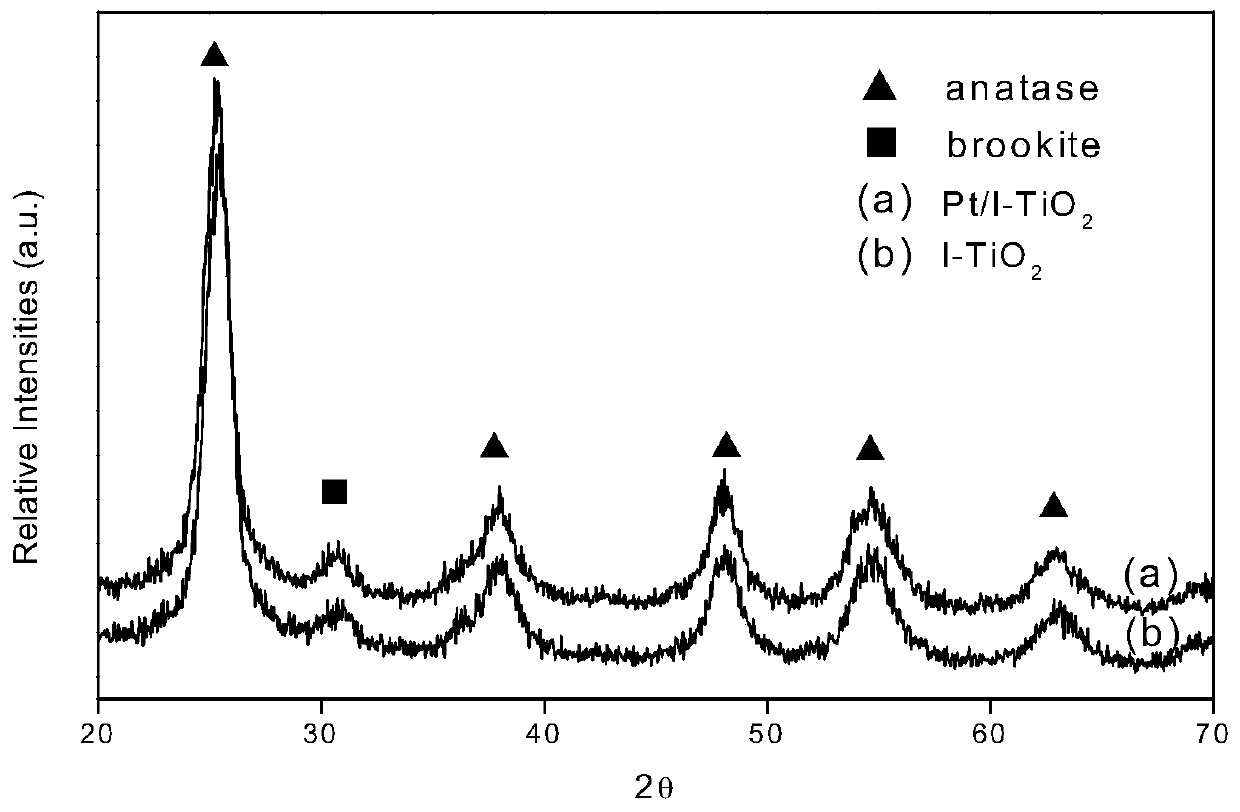

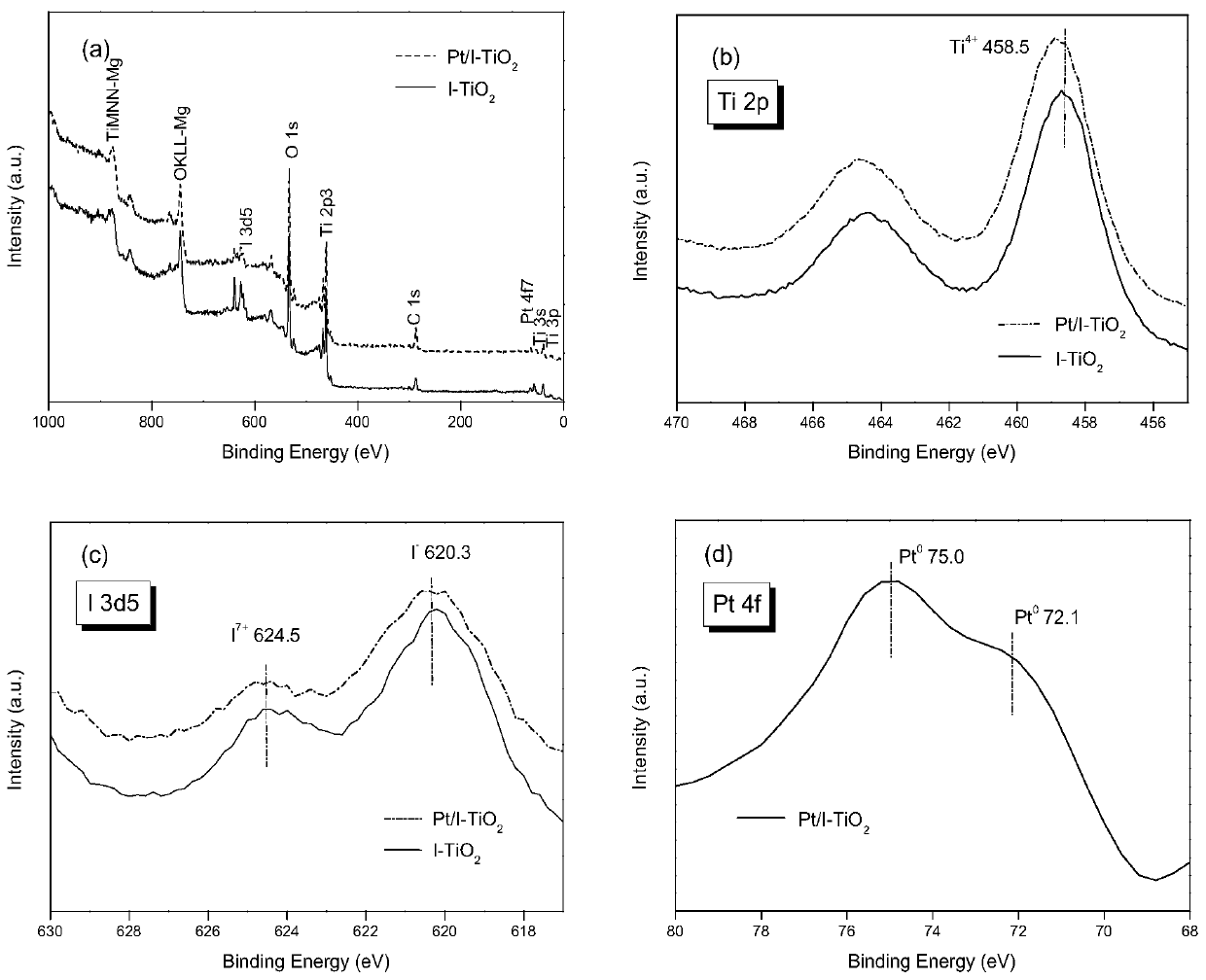

[0037] The heat-sensitive photocatalytic spray gel of the present embodiment is made of the following raw materials in parts by weight: 3 parts of platinum and iodine co-doped modified titanium dioxide nanopowders loaded with chitosan with a particle size of less than or equal to 10 μm as the photocatalytic material, 0.04 parts of sodium alginate, 7.5 parts of heat-sensitive cellulose and 750 parts of deionized water; the heat-sensitive cellulose is hydroxypropyl methylcellulose; the chitosan-loaded platinum and iodine co-doped modified titanium dioxide nanopowder The preparation method is:

[0038] S1. Dissolve 1.5g of iodic acid in 20mL of deionized water, then add 30mL of absolute ethanol a, 15mL of acetic acid and 3mL of polyethylene glycol in sequence, and stir evenly to obtain a mixed solution A; After the butyl ester and 30mL of absolute ethanol b are mixed evenly, they are added dropwise to the mixed solution A to react to obtain the mixed solution B; the polyethylene ...

Embodiment 2

[0066] The heat-sensitive photocatalytic spray gel of the present embodiment is made of the following raw materials in parts by weight: 2 parts of platinum and iodine co-doped modified titanium dioxide nanopowders loaded with chitosan with a particle size of less than or equal to 10 μm as the photocatalytic material, 0.05 parts of sodium alginate, 5 parts of heat-sensitive cellulose and 500 parts of deionized water; the photocatalytic material is chitosan-loaded platinum and iodine co-doped modified titanium dioxide nanopowder; the chitosan-loaded platinum and The preparation method of iodine co-doped modified titanium dioxide nanopowder is:

[0067] S1. Dissolve 1.5g of iodic acid in 20mL of deionized water, then add 30mL of absolute ethanol a, 15mL of acetic acid and 3mL of polyethylene glycol in sequence, and stir evenly to obtain a mixed solution A; After the butyl ester and 30mL of absolute ethanol b are mixed evenly, they are added dropwise to the mixed solution A to rea...

Embodiment 3

[0075] The heat-sensitive photocatalytic spray gel of the present embodiment is made of the following raw materials in parts by weight: 4 parts of platinum and iodine co-doped modified titanium dioxide nanopowders loaded with chitosan with a particle size of less than or equal to 10 μm as the photocatalytic material, 0.025 parts of sodium alginate, 10 parts of heat-sensitive cellulose and 1000 parts of deionized water; the heat-sensitive cellulose is hydroxypropyl methylcellulose; the chitosan-loaded platinum and iodine co-doped modified titanium dioxide nanopowder The preparation method is:

[0076] S1. Dissolve 1.5g of iodic acid in 20mL of deionized water, then add 30mL of absolute ethanol a, 15mL of acetic acid and 3mL of polyethylene glycol in sequence, and stir evenly to obtain a mixed solution A; After the butyl ester and 30mL of absolute ethanol b are mixed evenly, they are added dropwise to the mixed solution A to react to obtain the mixed solution B; the polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com