Coated CoNi/Al2O3 catalyst as well as preparation method and application thereof

A catalyst and coating technology, which is used in the synthesis and catalytic application of advanced nano-catalysts, can solve the problems of unfavorable large-scale preparation, cumbersome preparation methods, and poor catalyst activity, and achieve favorable catalytic activity, high CH4 selectivity, The effect of excellent life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 22.51g of aluminum nitrate was dissolved in 240ml of water to obtain an aluminum salt solution with a concentration of 0.25mol / L, then 0.46g of cobalt hydroxide and 0.46g of nickel hydroxide were added to the aluminum salt solution and stirred at room temperature for 24h to obtain a solution containing nickel and A uniform mixed sol of aluminum, the obtained mixed sol was baked at 80°C for 48 hours to obtain a mixed gel, and the obtained mixed gel was fired at 400°C for 4 hours under a hydrogen atmosphere to obtain a coated CoNi / Al with a loading capacity of 16%. 2 o 3 catalyst.

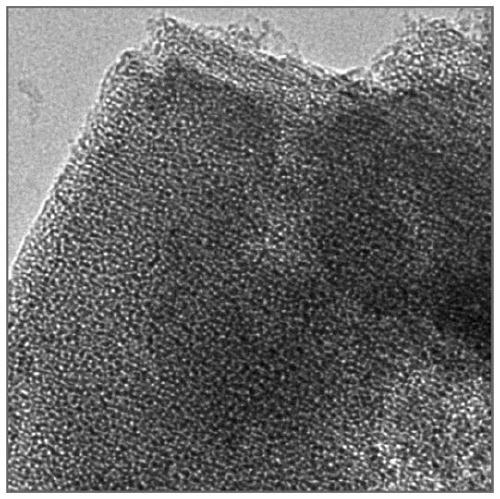

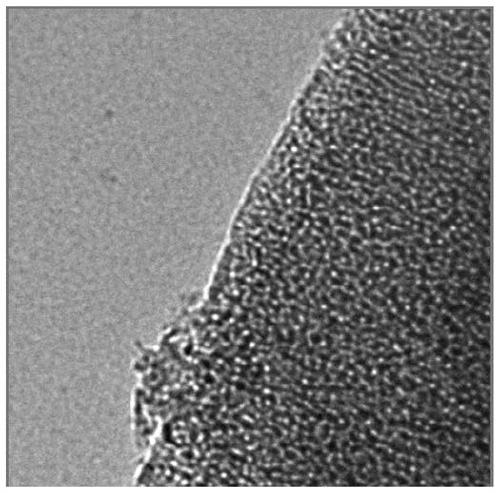

[0032] The morphology of the product prepared in this embodiment is characterized by transmission electron microscope, as figure 1 with figure 2 As shown, the prepared catalyst has a porous coating morphology, which is conducive to the high dispersion of the catalyst, and the porous structure is conducive to limiting the growth of the catalyst and maintaining the catalytic activity.

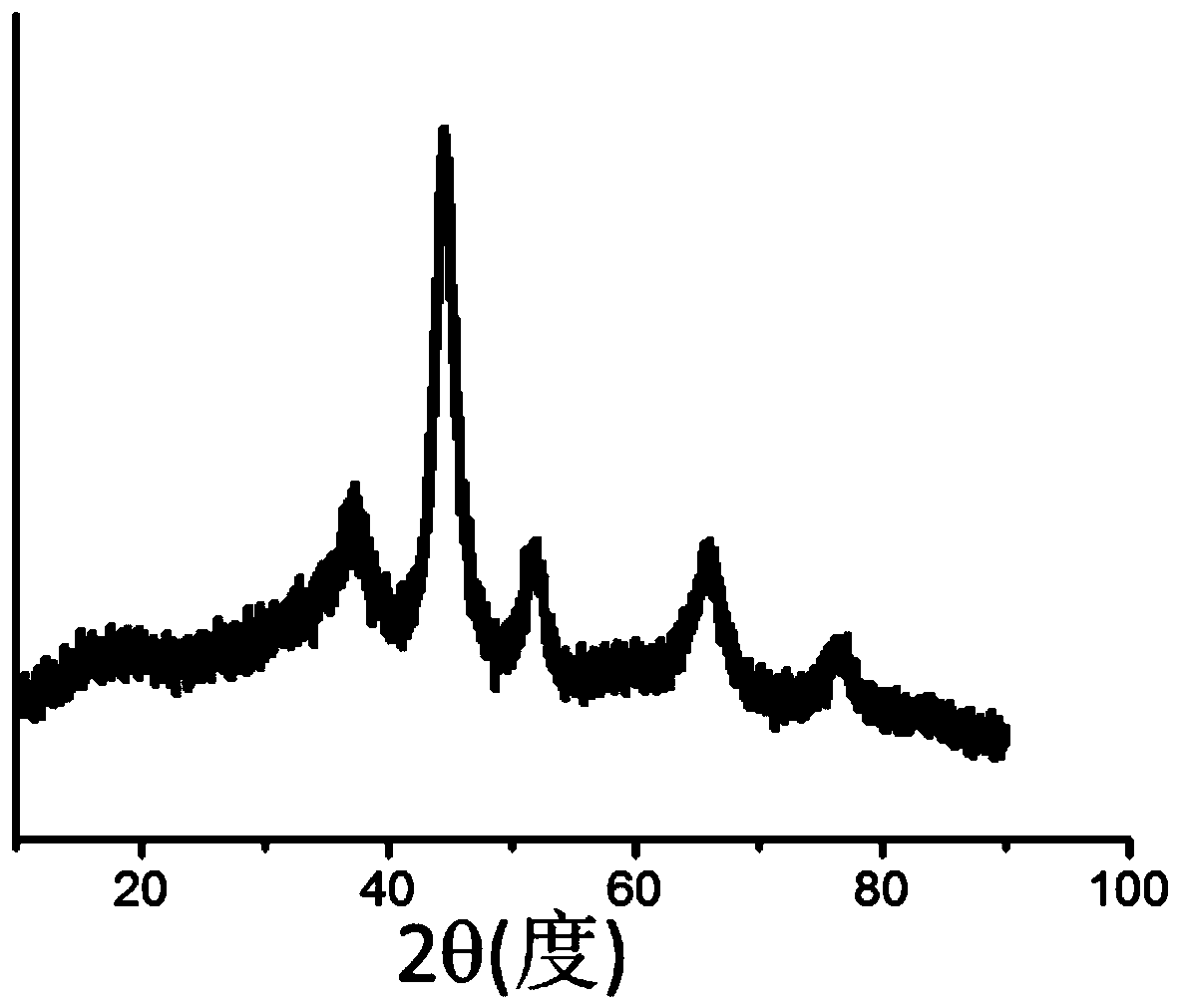

[003...

Embodiment 2

[0036] 7.2g of aluminum chloride was dissolved in 30ml of water to obtain an aluminum salt solution with a concentration of 1mol / L, then 0.92g of cobalt hydroxide and 0.92g of nickel hydroxide were added to the aluminum salt solution and stirred at room temperature for 72h to obtain a solution containing nickel and A homogeneous mixed sol of aluminum, the obtained mixed sol was baked at 120°C for 12h to obtain a mixed gel, and the obtained mixed gel was fired at 600°C under a hydrogen atmosphere for 1h to obtain a coated CoNi / Al with a loading capacity of 44%. 2 o 3catalyst. The morphology of the product was characterized by transmission electron microscopy, as Figure 5 As shown, the catalyst prepared in Example 2 has a porous coating structure, which is beneficial to the maintenance of the catalytic activity of the catalyst.

Embodiment 3

[0038] Catalytic Methanation Test

[0039] The catalytic methanation reaction is tested on a fixed bed, and the specific test process will be described in detail in the following examples.

[0040] Get the coating type CoNi / Al that 0.1g embodiment prepares 2 o 3 The catalyst carries out the CO methanation reaction, which is carried out on a micro-reaction high-pressure fixed bed-chromatographic analysis integrated system device. Sieve the catalyst pellets, select catalyst particles (40-60 mesh) and fill them in a stainless steel reaction tube with a quartz liner. 2 Reduction under the atmosphere for 2h. After reduction, adjust the temperature to the desired reaction temperature and switch to H 2 React with a mixed atmosphere of CO. One hour after the start of the reaction, samples were taken and analyzed with a six-way valve, and samples were taken every other hour for analysis thereafter.

[0041] The analysis of raw gas and products is carried out by an online gas chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com