Low-cost ZnNCN material preparation method

A low-cost, TRD-ZIF-8 technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of large particle size, small specific surface area and high production cost of nanoparticles, and achieve small particle size, large specific surface area and electrochemical performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

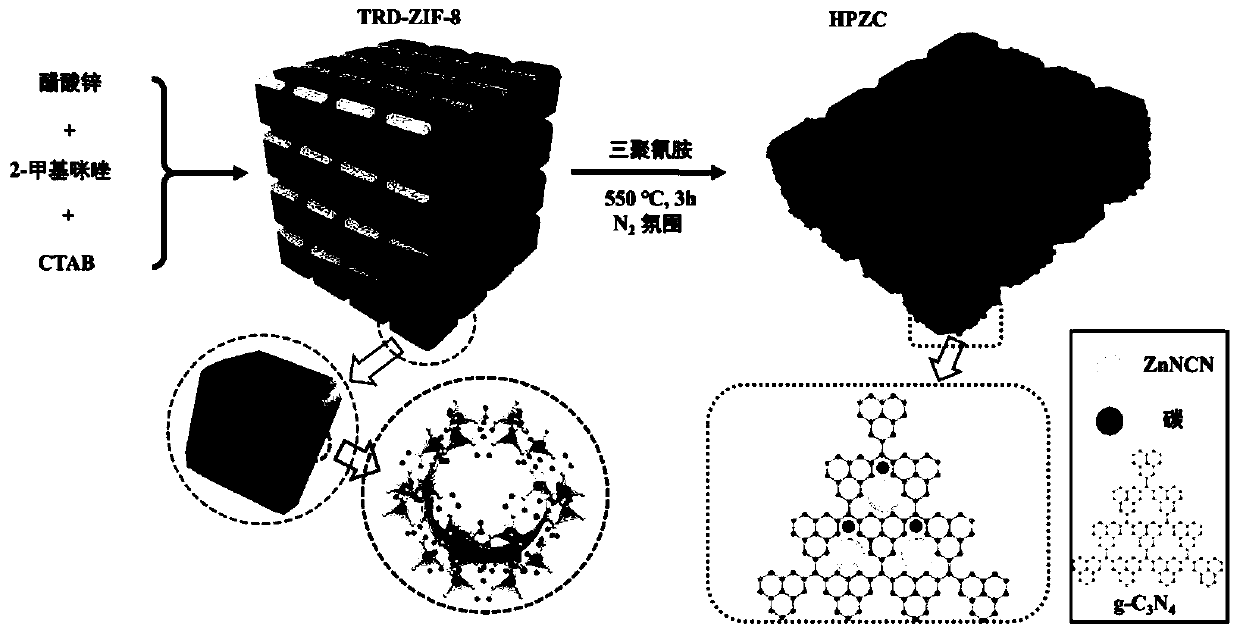

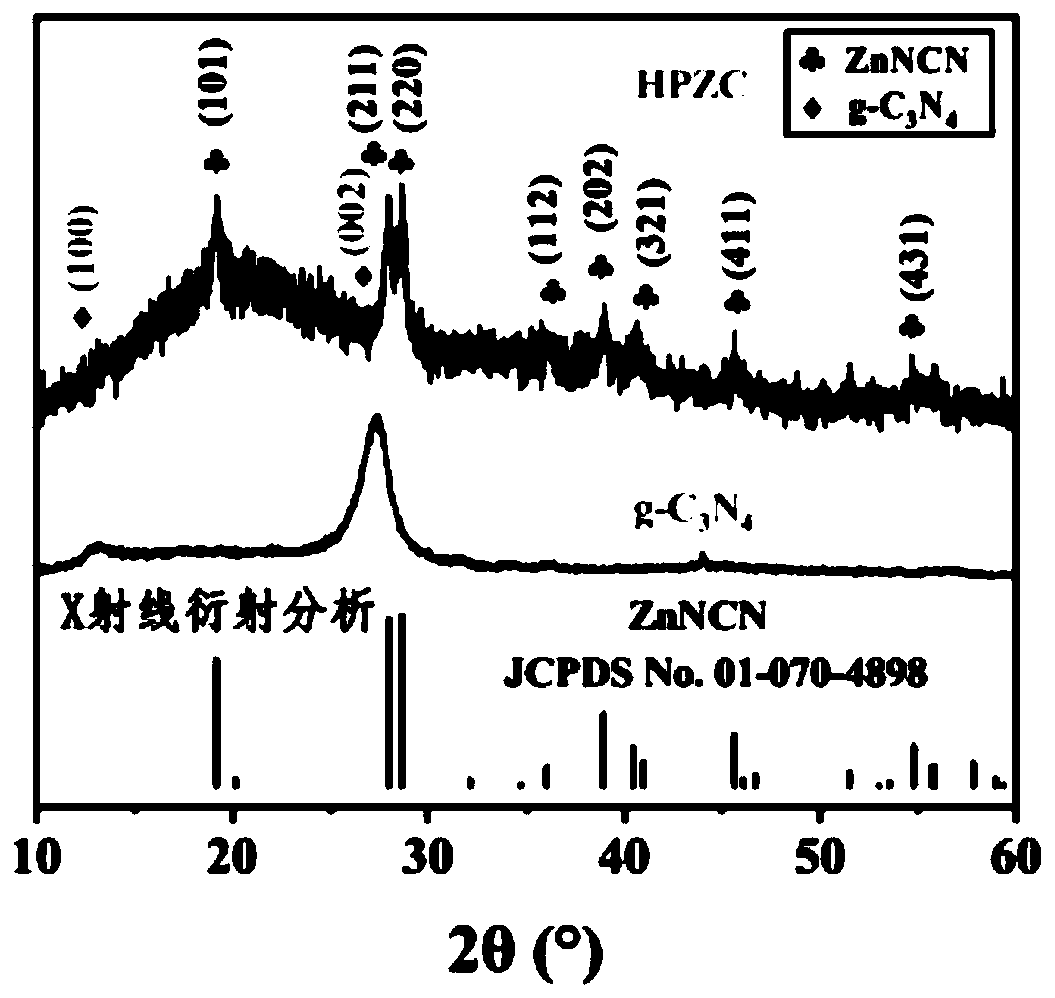

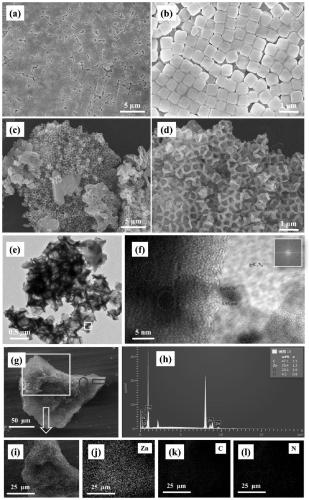

[0023] refer to Figure 1-5 , a low-cost ZnNCN material preparation method, comprising the following steps:

[0024] S1: Synthesis of truncated rhombohedral dodecahedral zeolite imidazolate framework-8 (TRD-ZIF-8) nanoparticles: Zn(CH 3 COO) 2 2H 2 O (600 mg) in 10 ml of aqueous solution was added to 10 ml of aqueous solution of 2-methylimidazole (0.54 mM) and CTAB (2.58 mM), stirred slowly for a few seconds, and after 10 minutes, the original transparent solution turned white Solution, after standing at room temperature for 3h, centrifuged at 9000r.p.m, enriched in a 50mL centrifuge tube, then the resulting TRD-ZIF-8 nanoparticles were washed 3 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com