An oil and gas well casing liquid resin plugging and squeezing tool and construction technology

A technology of liquid resin and construction technology, which is used in wellbore/well components, sealing/isolation, earth-moving drilling, etc. It can solve the problems of many times of tripping the pipe string, wasting materials, and retaining plugging agents, and reducing the The effect of tripping risk, reducing tripping cost and saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

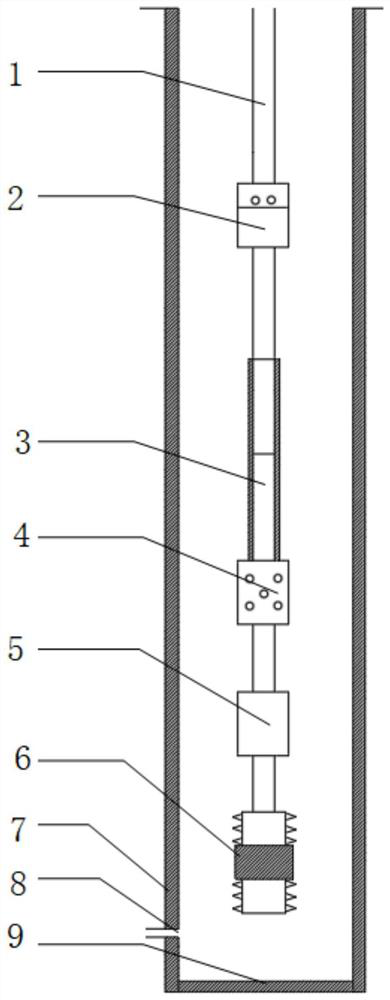

Method used

Image

Examples

Embodiment 1

[0053] Zhen* Well was put into production on October 4, 2010. The initial daily liquid production was 4.86m3, daily oil production was 3.15t, water content was 22.8%, dynamic liquid level was 1309m, and salt content was 71309mg / L; The liquid level is 259m, and the salt content is 23380mg / L. The analysis shows that the casing is damaged. Decided to do chemical plugging.

[0054] (1) Pull out the pipe string from the original well.

[0055] (2) Through the well.

[0056] Specifically: lower the Φ118mm×1.5m through well gauge, and lead to the bottom of the artificial well.

[0057] (3) Find leaks.

[0058] Specifically, the packer is used, and the whole well section is tested for leakage, and the location of the leakage point is determined to be 1608m.

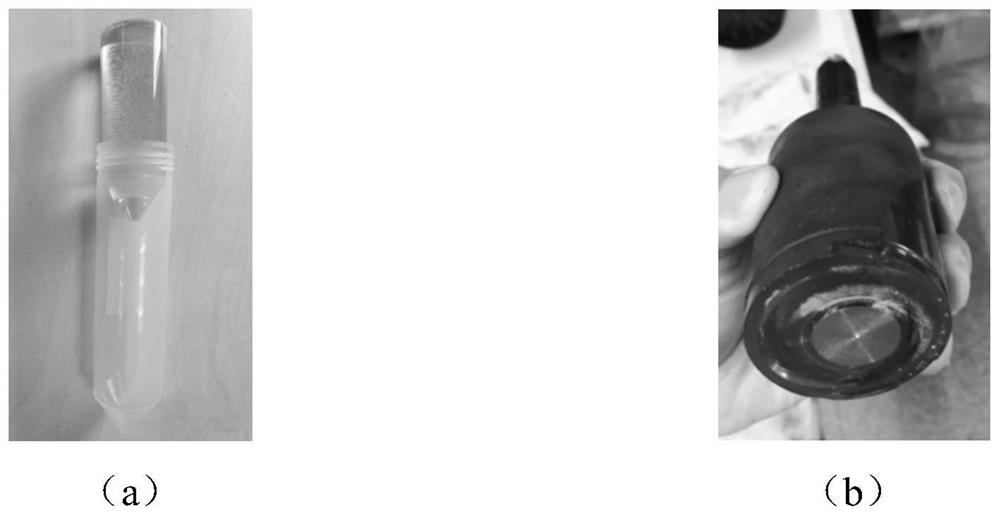

[0059] (4) Tool lamination.

[0060] Specifically: use low-pressure polyethylene tape to wrap the tool string, with a thickness of 1.5mm, tighten the film tape, and the width of the blank holder is 12mm. Grow 20cm and stuff...

Embodiment 2

[0075] The Huan* Well was put into production on March 6, 2012, with an initial daily oil production of 2.86t, a water cut of 25.3%, a dynamic liquid level of 1433m, and a salt content of 72,415mg / L; The salt was 21089mg / L, and the analysis indicated that the casing was damaged. Decided to do chemical plugging.

[0076] (1) Pull out the pipe string from the original well.

[0077] (2) Through the well.

[0078] Specifically: lower the Φ118mm×1.5m through well gauge, and lead to the bottom of the artificial well.

[0079] (3) Find leaks.

[0080] Specifically, the packer is used, and the whole well section is tested for leakage, and the location of the leakage point is determined to be 1608m.

[0081] (4) Tool lamination.

[0082] Specifically: use low-pressure polyvinyl chloride tape to wrap the tool string, with a thickness of 1.2mm, tighten the film tape, and the width of the blank holder is 15mm. The tool string covers the tool surface from the seat sealing tool to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com