A clean production control method for vertical electric furnace steelmaking

A clean production, electric furnace steelmaking technology, applied in cleaning methods and appliances, electric furnaces, chemical instruments and methods, etc., can solve problems such as inconsistency in system control, the impact of clean production in workshops, and unfavorable occupational health of on-site production workers. Reduce the production of dioxins, ensure cleaner production, and improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

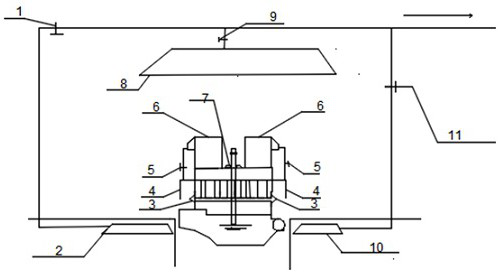

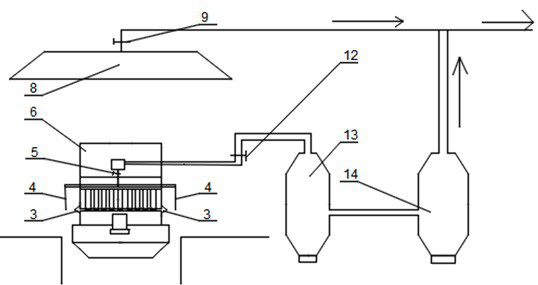

[0025] This embodiment is a clean production control method for vertical electric furnace steelmaking, which includes adjusting the primary flue gas and secondary flue gas control systems at all levels in each smelting period according to the scrap steel cone ratio and corresponding to different flue gas control system models The opening of the valve is used to ensure the collection rate of flue gas. The specific model control requirements are as follows:

[0026]When the scrap pile ratio used is ≤0.3t / m³ as raw material. Feeding period: Feeding period: valve 1 of the flue gas collection hood on the tapping side, valve 11 of the flue gas collection hood on the slag discharge side, the secondary flue gas secondary control system is closed, and does not work; the roof collection hood valve 9 secondary smoke The opening degree of the first-level gas control system is 100%; the opening degree of the ring-shaped collection cover valve 5 around the shaft is 100% for the primary flue...

Embodiment 2

[0029] This embodiment is a clean production control method for vertical electric furnace steelmaking, which includes adjusting the primary flue gas and secondary flue gas control systems at all levels in each smelting period according to the scrap steel cone ratio and corresponding to different flue gas control system models The opening of the valve is used to ensure the collection rate of flue gas. The specific model control requirements are as follows:

[0030] When the scrap steel used is 0.3t / m³<heap ratio<0.9t / m³ as the raw material. Feeding period: valve 1 of the flue gas collection hood on the tapping side, valve 11 of the flue gas collection hood on the slag discharge side, the secondary flue gas secondary control system is closed and does not work; the roof collecting hood valve 9 secondary flue gas primary The opening degree of the control system is 100%; the opening degree of the primary flue gas secondary control system of 5 primary flue gas secondary control syst...

Embodiment 3

[0033] This embodiment is a clean production control method for vertical electric furnace steelmaking, which includes adjusting the primary flue gas and secondary flue gas control systems at all levels in each smelting period according to the scrap steel cone ratio and corresponding to different flue gas control system models The opening of the valve is used to ensure the collection rate of flue gas. The specific model control requirements are as follows:

[0034] When the scrap pile ratio used is ≥0.9t / m³ as raw material. Feeding period: valve 1 of the flue gas collection hood on the tapping side, valve 11 of the flue gas collection hood on the slag discharge side, the secondary flue gas secondary control system is closed and does not work; the roof collecting hood valve 9 secondary flue gas primary The opening degree of the control system is 100%; the opening degree of the primary flue gas secondary control system of 5 primary flue gas secondary control systems is 100%; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com