A mobile device for steel pipe welding of steel pipe tower

A mobile device, tower steel pipe technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of difficult forklift operation, high construction risk, large manpower consumption, etc., and achieves compact structure, good moving stability, and reasonable arrangement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

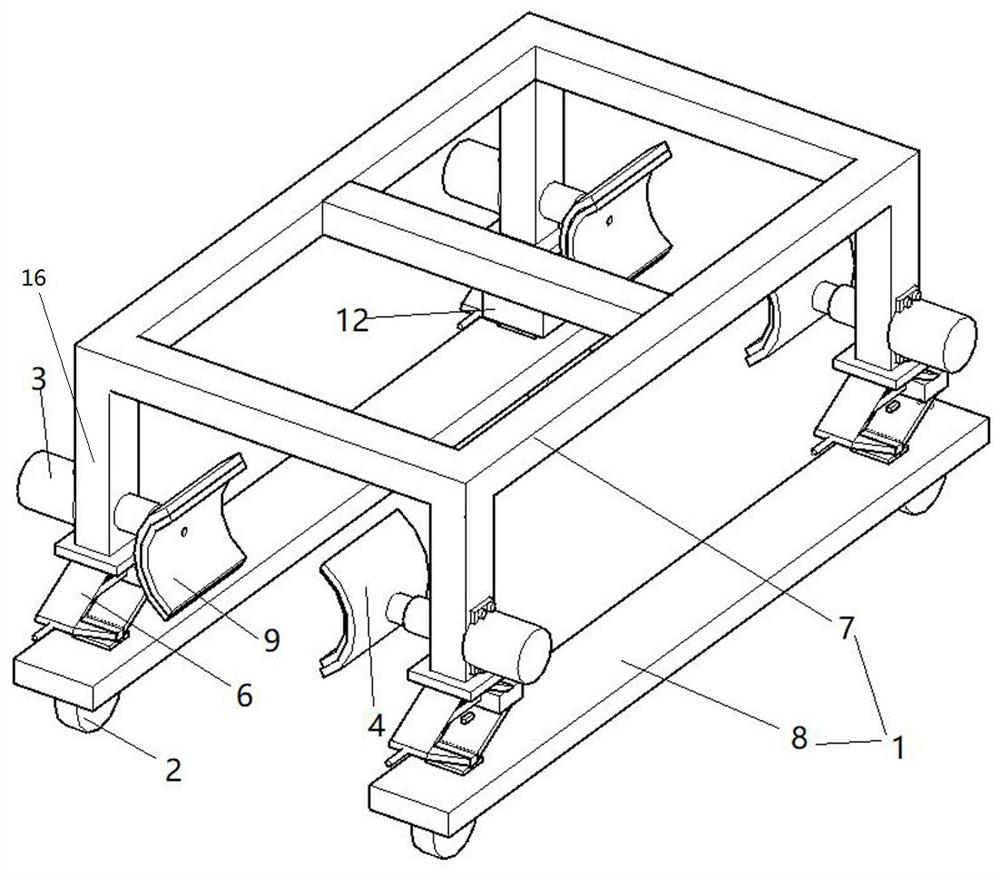

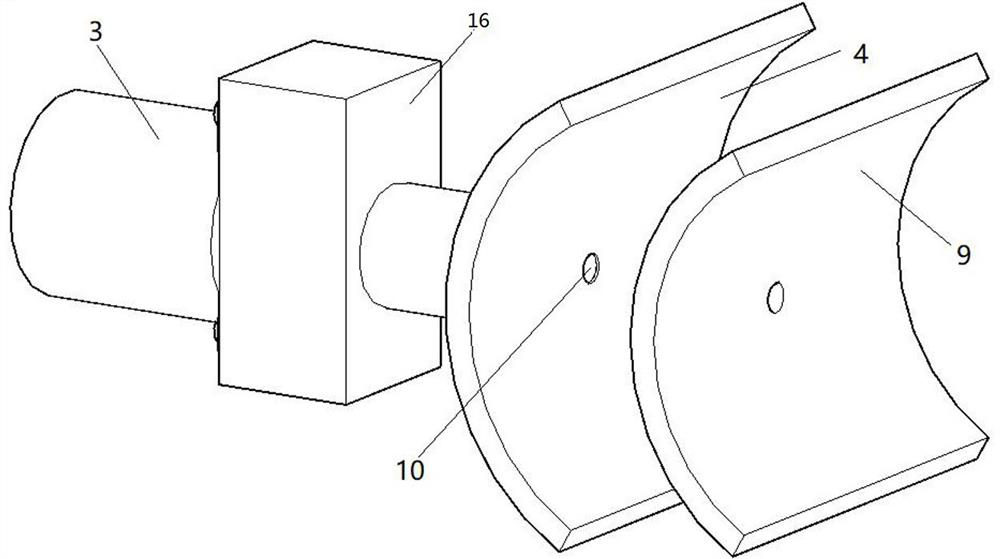

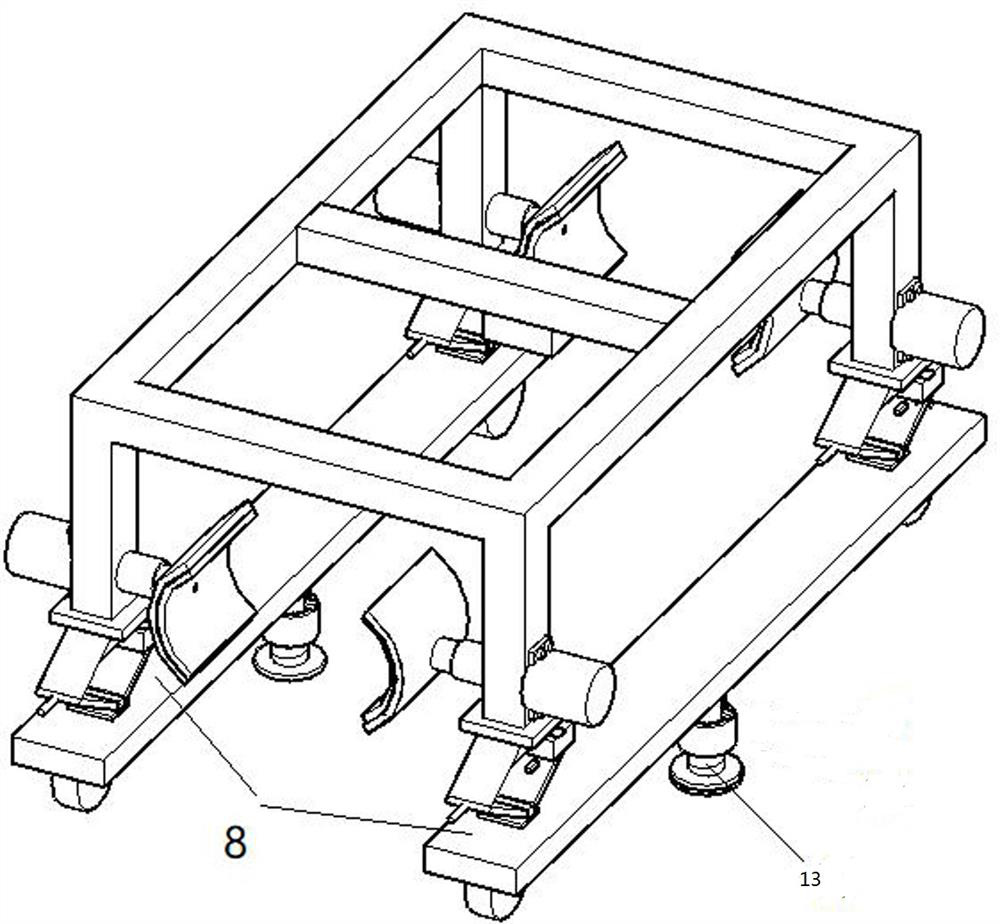

[0032] like Figure 1-2 Shown is the first embodiment of the present invention, a steel pipe welding device, including a fixed frame 1, the fixed frame 1 is composed of an upper fixed frame 7 and a lower fixed frame 8, and the lower fixed frame 8 is two rectangular tubes parallel to each other One, the four corners of the bottom surface of the fixed frame 1 are provided with universal brake wheels 2, that is, universal brake wheels 2 are respectively installed at both ends of the lower end faces of the two rectangular tubes. The upper fixed 7 frame is made up of three rectangular tubes two parallel to each other, two rectangular tubes three welded on two ends of three rectangular tubes two and four vertical bars 16 vertically welded on the bottom end faces of the three rectangular tubes. Four clamping assemblies are arranged symmetrically on the fixed frame 1, and the clamping assembly includes an electric push rod 3 and an arc-shaped plate 4 fixed on the end of the electric p...

Embodiment 3

[0038] like Image 6 Shown is the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the arc-shaped plate 4 is detachably connected to the end of the electric push rod 3, and the end of the electric push rod 3 is welded with an open end. Cylinder 24, inside the cylinder 24, an internal thread is machined by a lathe, and a round rod 25 is welded to the center of the outer peripheral surface of the arc-shaped plate 4, and an external thread matching the internal thread is processed on the outer peripheral surface of the round rod 25 through a die. The matching of the internal thread and the external thread realizes the detachable connection between the arc plate 4 and the electric push rod 3 .

Embodiment 4

[0040] like Figure 7-8 Shown is the fourth embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that two cross bars 14 are welded on the top of the upper fixing frame 7, and two slide blocks 15 are slidably connected on each cross bar 14. Block 15 is a cuboid block structure with a round hole processed by a lathe inside. The sliding bearing 26 is fixed by glue in the round hole. Sliding, the lower end surface of the slider 15 vertically fixes the vertical plate 27 by means of glue, etc., and the drive assembly that drives the slider 15 to move relatively or oppositely at the same time is set on the fixed frame 1. The drive assembly includes a rotating rod 28, which is rotatably connected to the slider On the block 15, the concave frame 29 is fixed by viscose on the left side of the slide block 15, and the rotating rod 28 is connected in the concave frame 29 by the rotation of the circular shaft. Break away from concave frame 29. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com