Manufacturing method of prefabricated assembled deep-arc wave-proof wall

A prefabricated assembly and manufacturing method technology, applied in the direction of breakwaters, manufacturing tools, molds, etc., can solve the problems of low qualified rate of steel bar protection layer, difficulty in uniform steel bar spacing, and easy pollution of steel bar skeletons, so as to save the need for reserved hole seals Blocking links, good construction quality, and the effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

[0057] The invention relates to a method for manufacturing a prefabricated deep circular arc wave wall, which comprises the following steps:

[0058] S1: Make a reinforcement cage based on the finalized tire frame;

[0059] S2: Place the reinforcement cage in the finalized formwork, pour concrete based on the finalized formwork, remove the finalized formwork after the concrete reaches strength, and form a prefabricated deep circular arc wave wall.

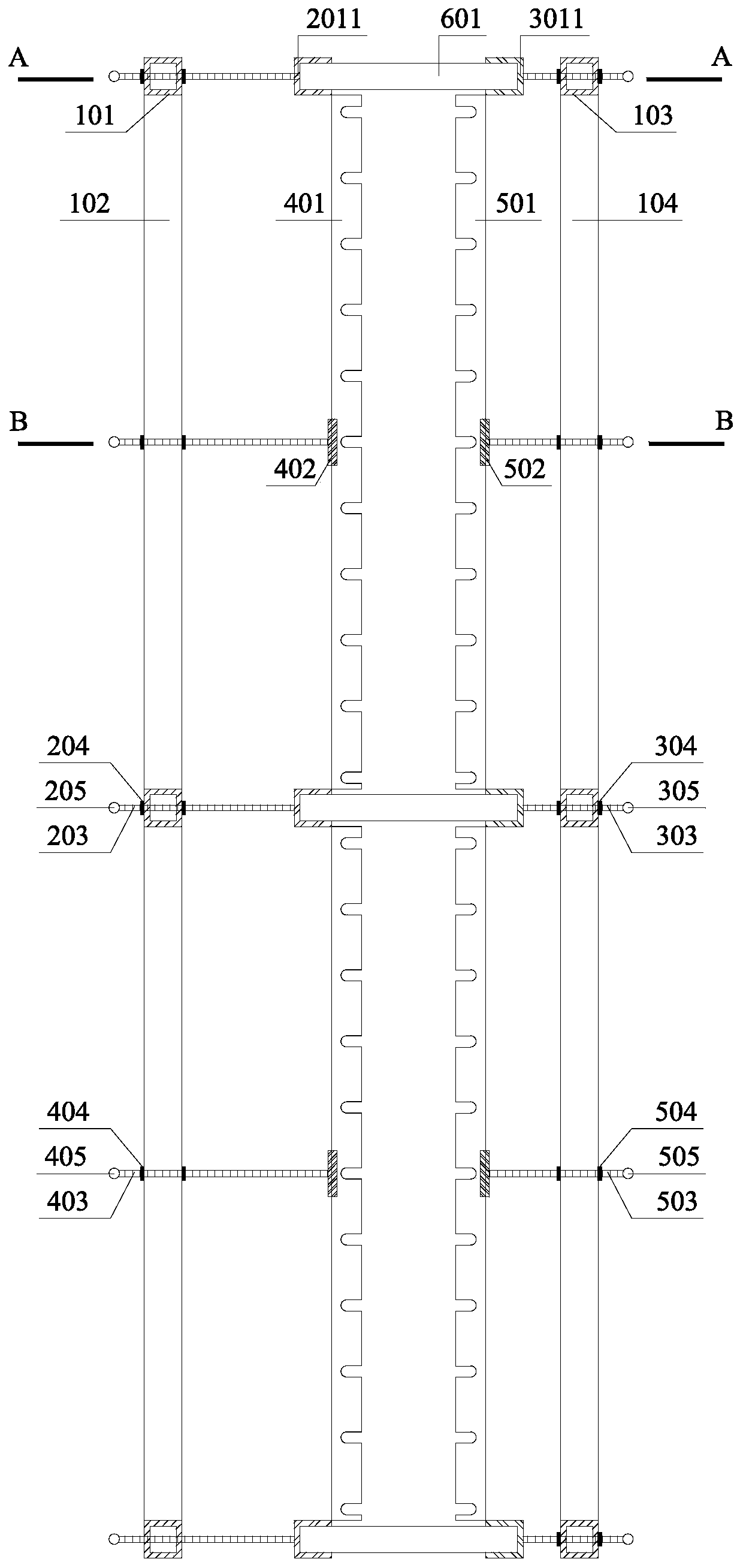

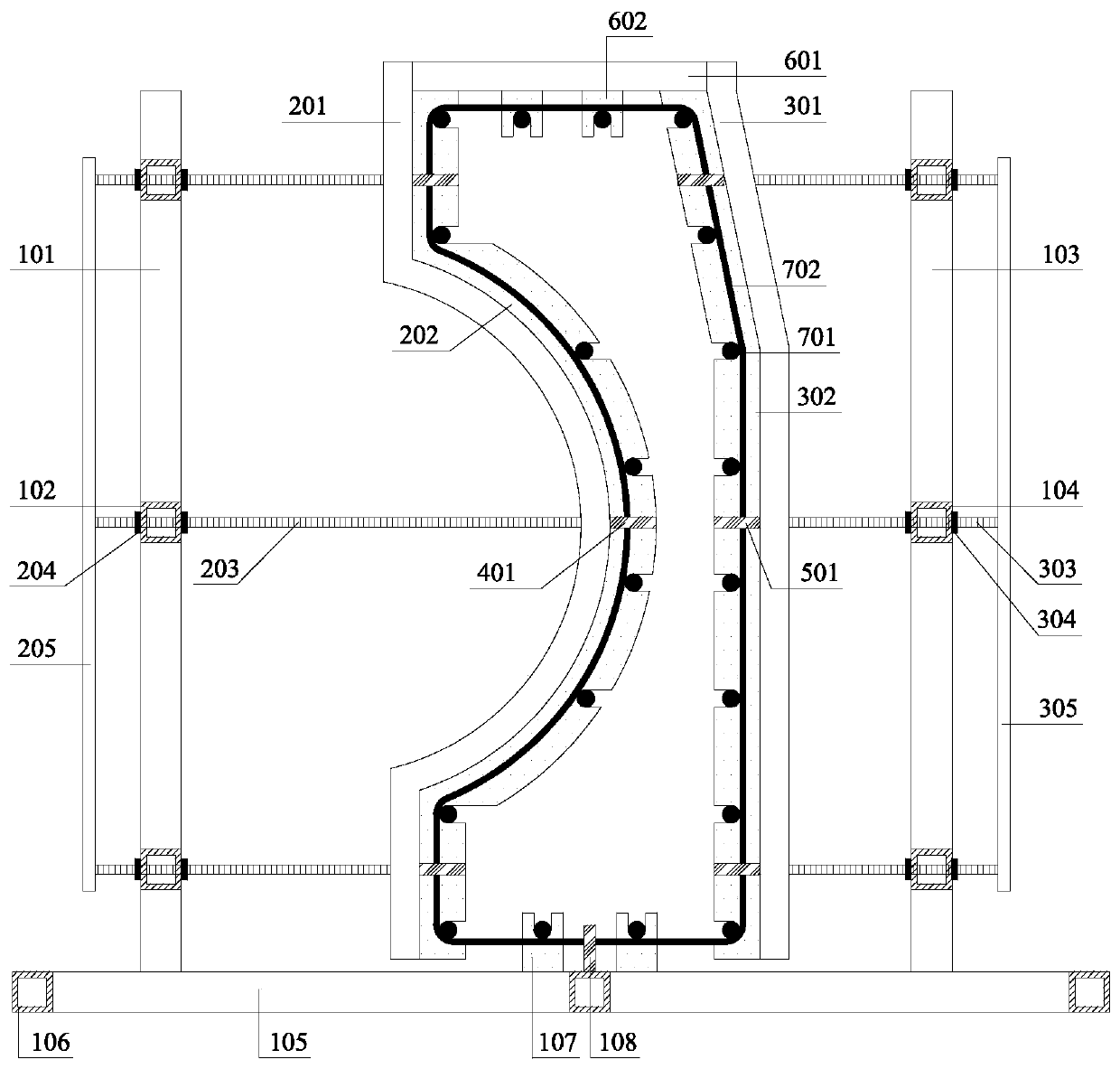

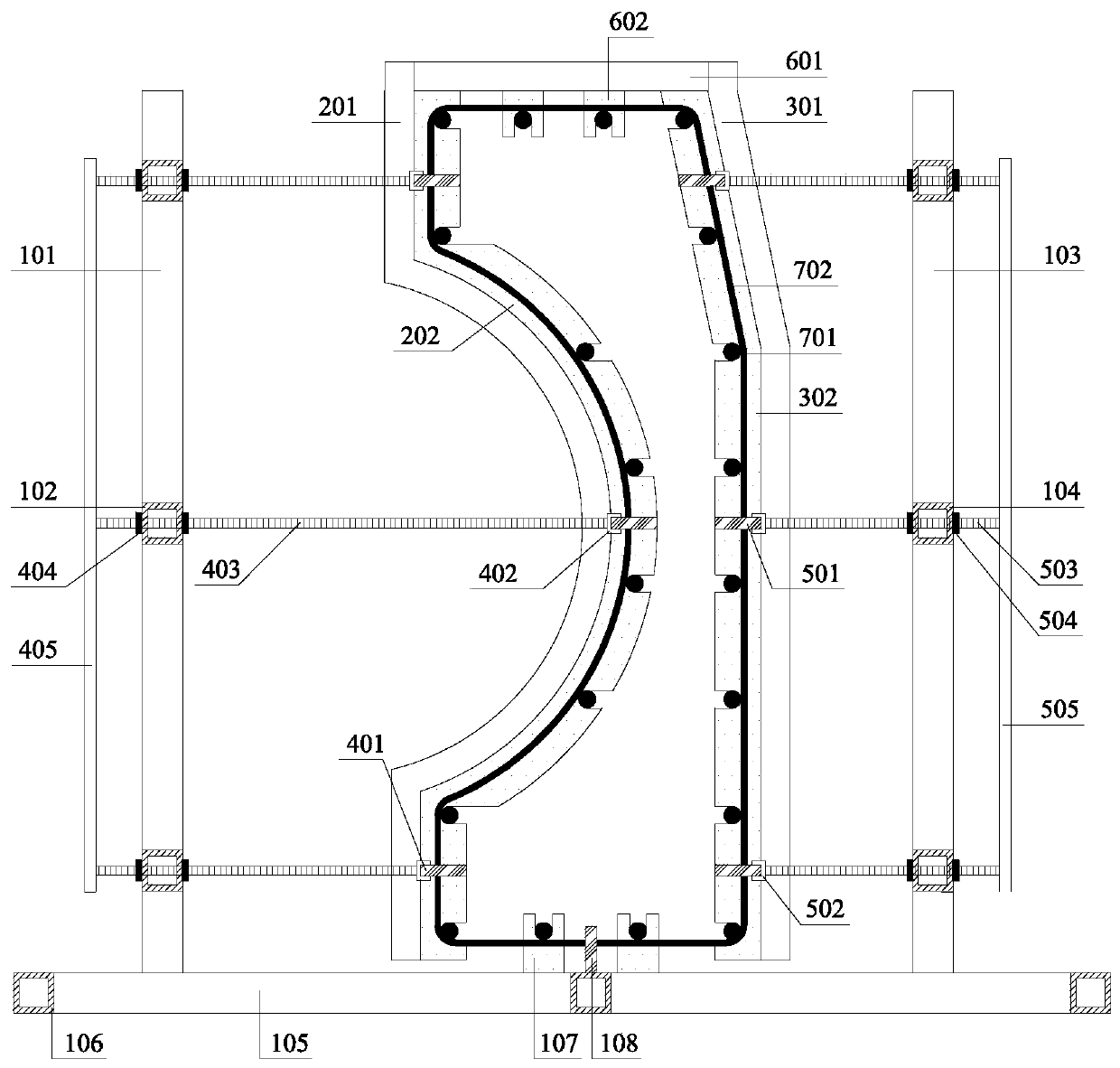

[0060] In step S1, the structure of the integrally formed and finalized tire frame of the deep circular arc anti-wave wall reinforcement cage is as follows: Figure 1~3 As shown, it includes a fixed frame 1, a main rib positioning frame 2 of an arc segment, a main rib positioning frame 3 of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com