Slitting device for electrolytic copper foil

A technology of electrolytic copper foil and mounting plate, which is applied in the field of electrolytic copper foil slitting device, can solve problems such as aluminum foil is easy to cause quality problems, circuit board short circuit, lithium battery is easy to cause breakdown accidents, etc., to maintain cleaning effect and ensure quality , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

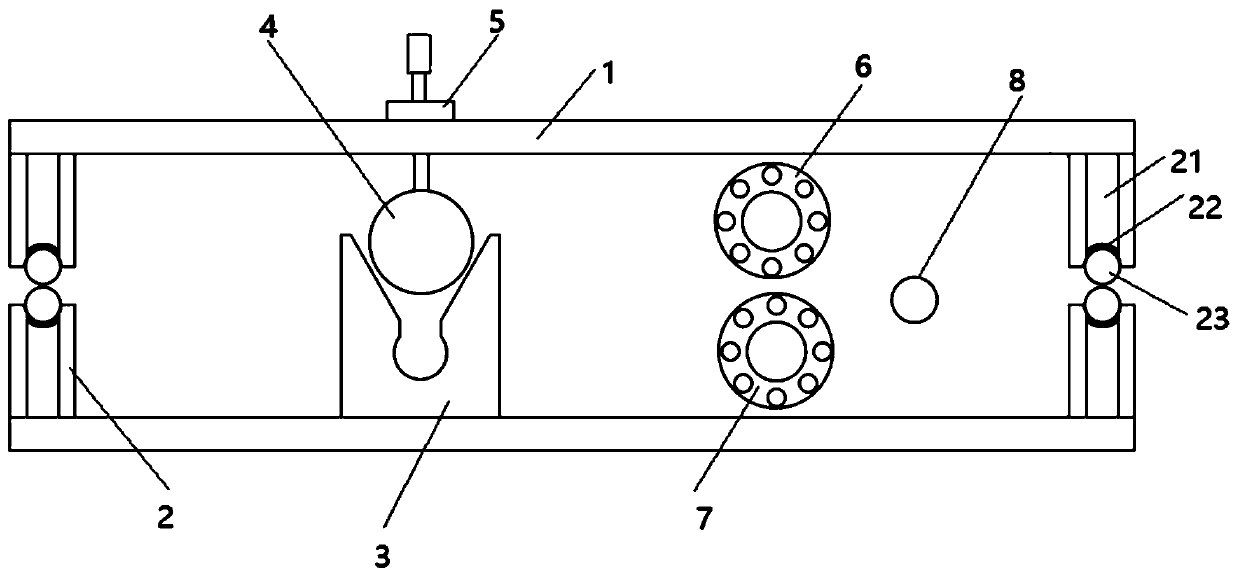

[0032] see Figure 1-8 , describe in detail in conjunction with the following examples:

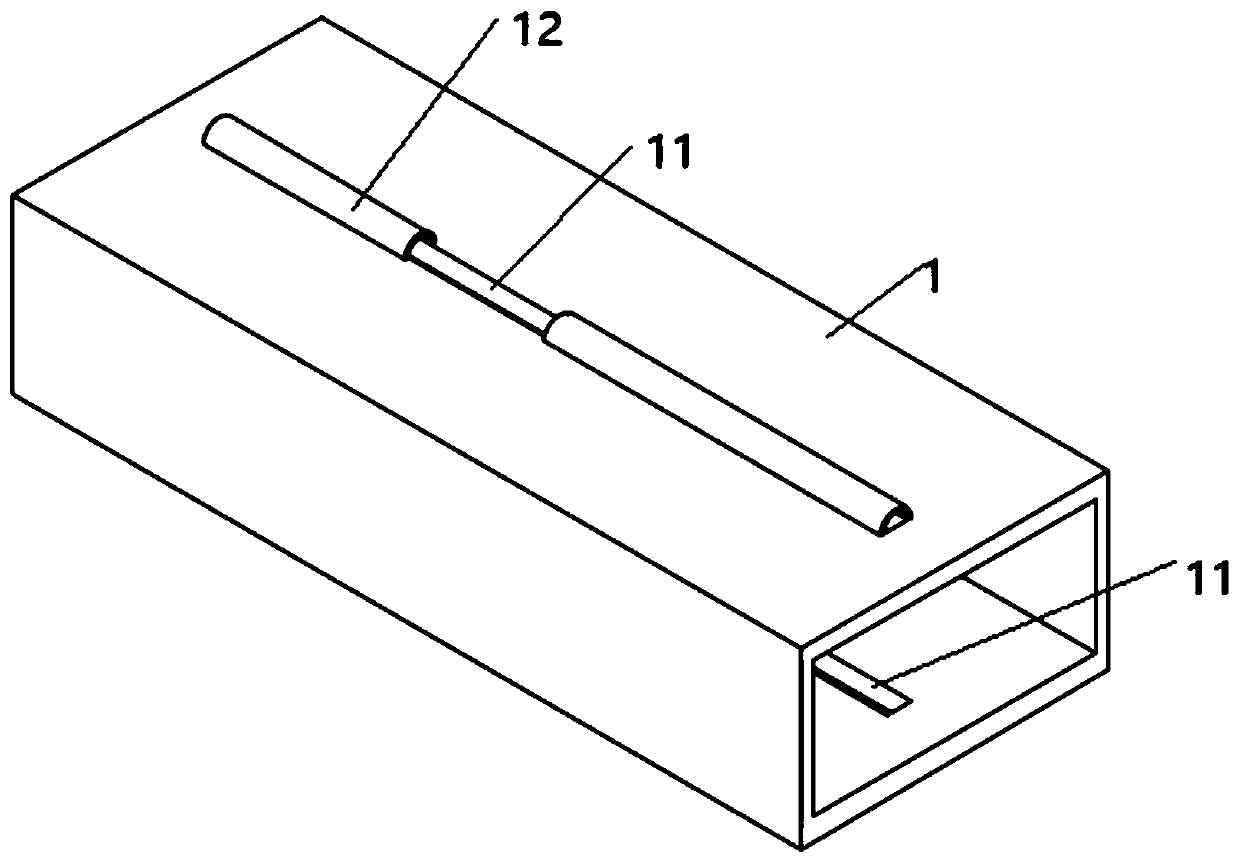

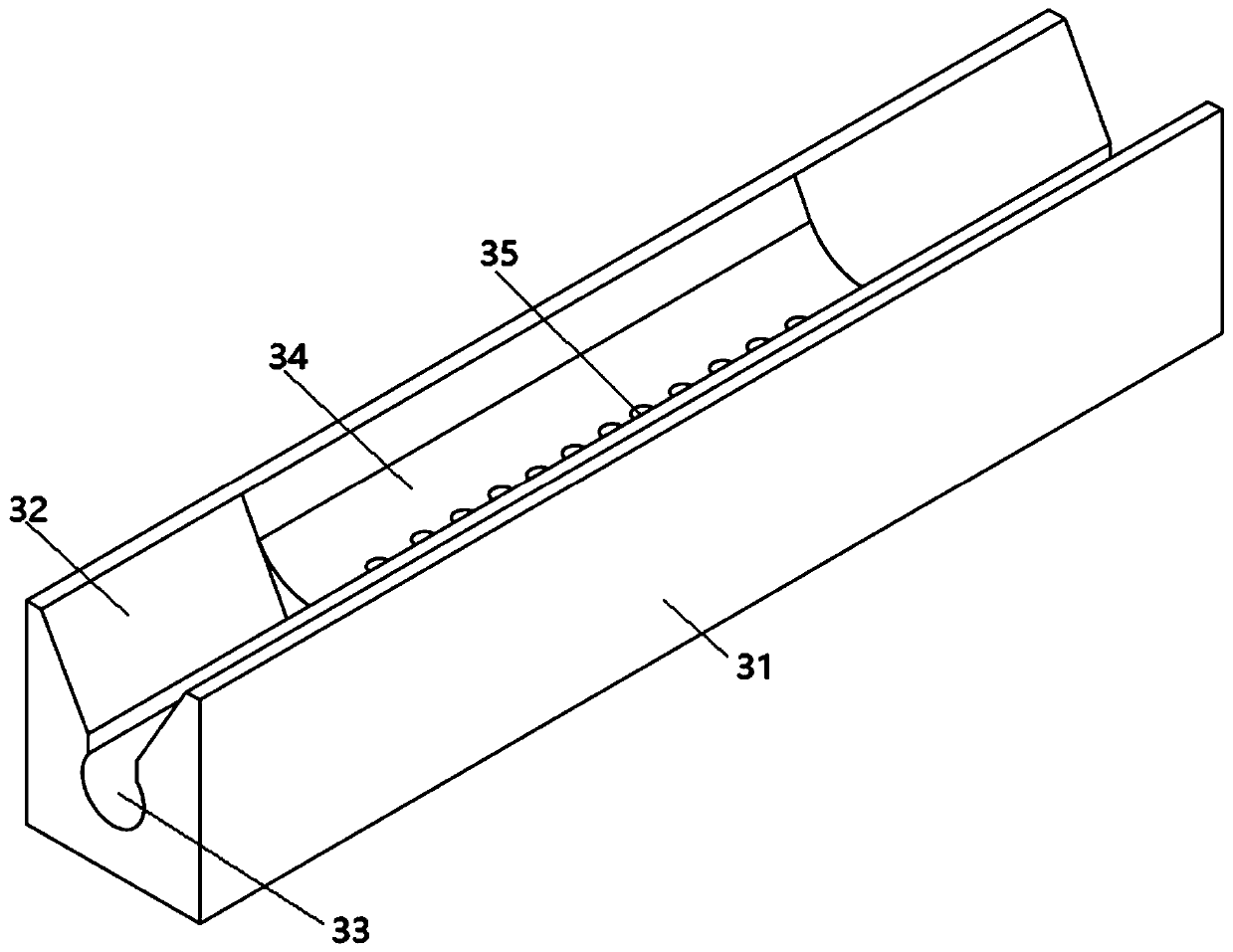

[0033] An electrolytic copper foil cutting device, such as figure 1 As shown, it includes a casing 1 with openings at both ends, a sealed guide roller 2 fixedly installed at both ends of the opening of the casing 1, and a dust collecting seat 3 fixedly installed in the casing 1, which is arranged above the dust collecting seat 3 and connected to the casing. 1 Rotatingly connected cutting roller 4, a cutting knife 5 arranged above the cutting roller 4 and slidingly connected with the casing 1, a first dust removal roller 6 and a second dust removal roller 7 arranged on one side of the dust collecting seat 3, The first dust removal roller 6 and the second dust removal roller 7 are rotatably installed on the casing 1, the first dust removal roller 6 is arranged above the second dust removal roller 7, and a guide roller 8 is also rotatably installed in the casing 1, and the guide roller 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com