Lens assembling equipment

A technology for assembling equipment and lenses, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem that manual assembly accuracy cannot meet high-definition and other problems, increase unit hourly production capacity, achieve full automation, and high assembly accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention and its outstanding advantages are described in detail below with reference to the accompanying drawings. In some embodiments, since the device is a left-right symmetrical mechanism, in order to simplify the description, the following embodiments of the present invention mainly introduce the mechanism of the left part of the device, and the structure of the right part is symmetrical or similar to the device.

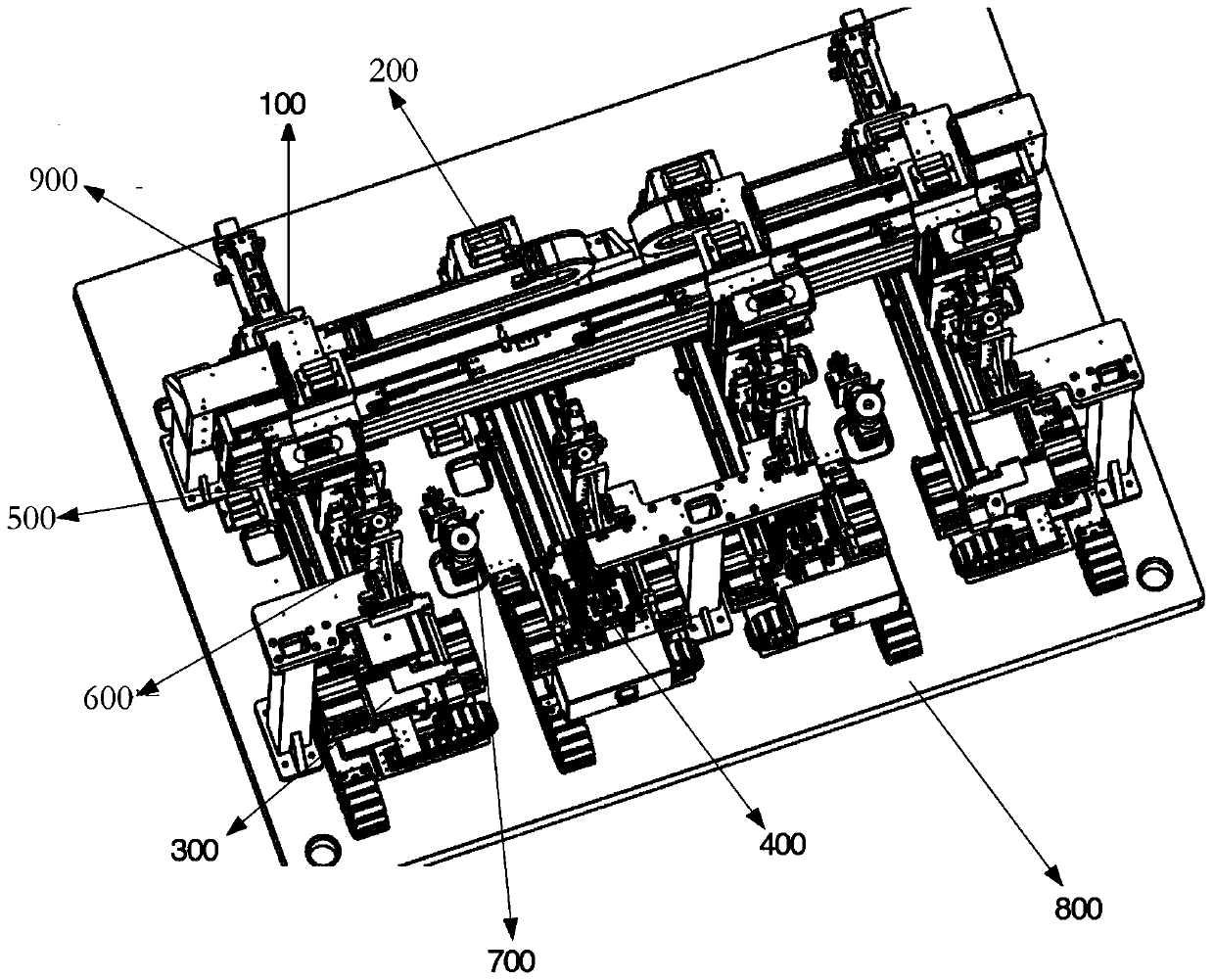

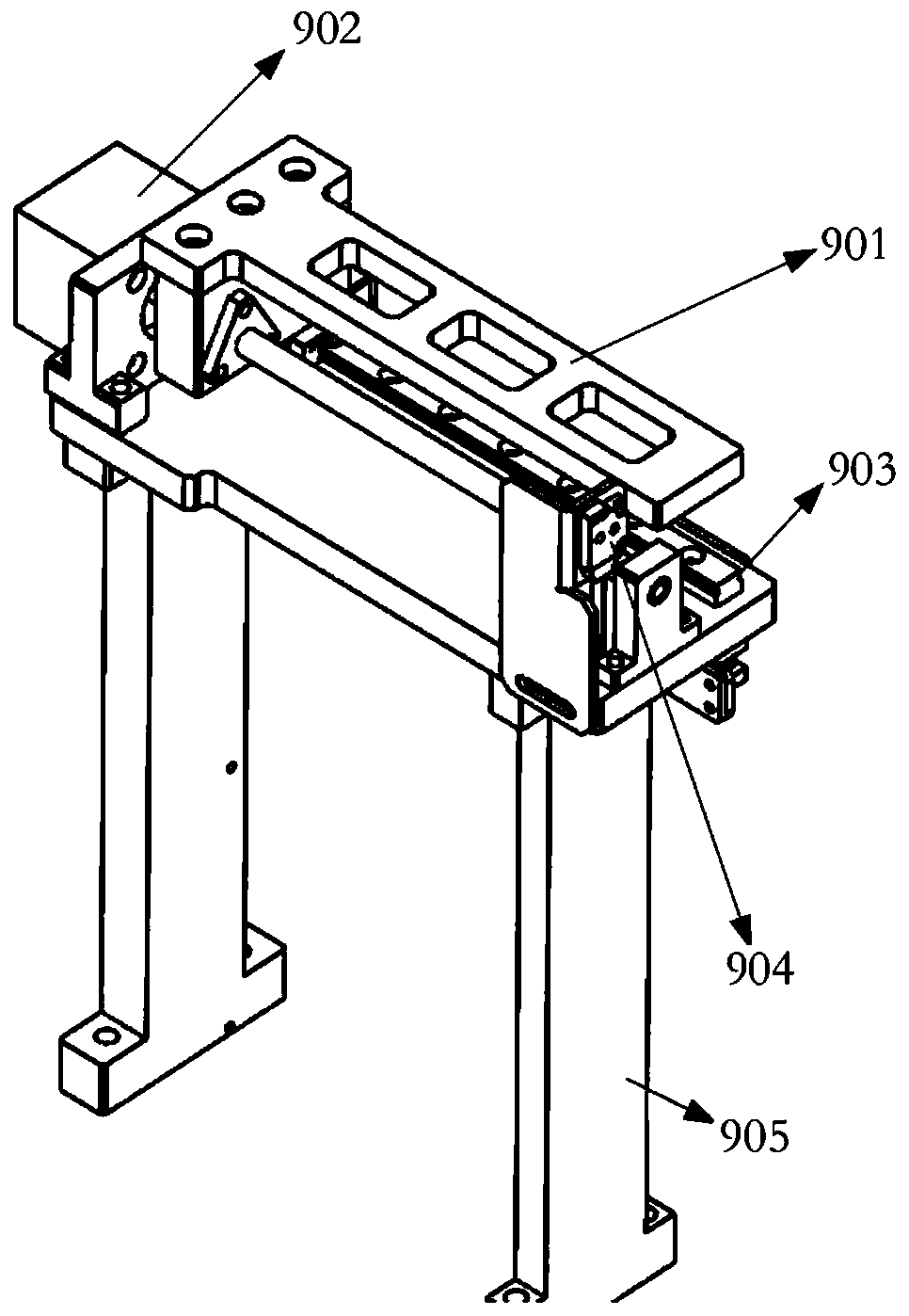

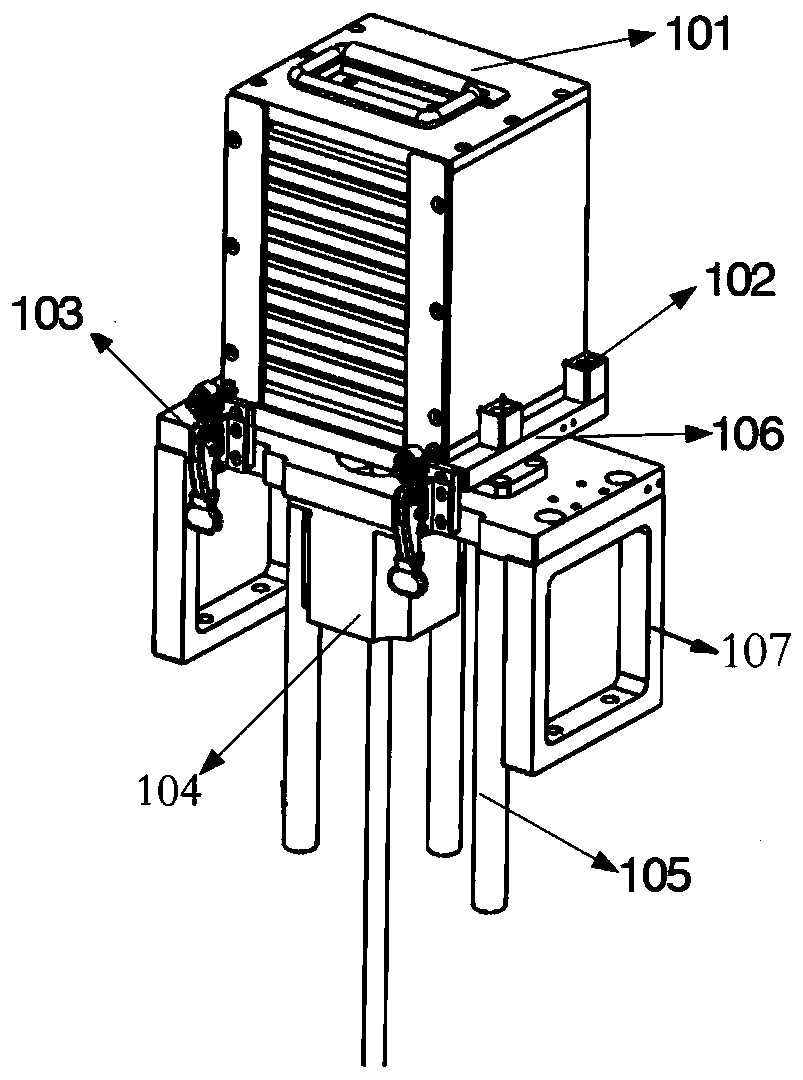

[0042] figure 1 The main body configuration of the embodiment of the present invention is exemplarily depicted. Generally speaking, the lens assembly equipment mainly includes a frame structure 800 (such as a rigid frame structure, which can be metal / alloy, hard insulating material, etc.) , lower flexibility), and the lens discharge push rod structure 900, the lens bin lifting structure 100, the mirror base bin lifting structure 200, the lens transport structure 300, the mirror base transport structure 400, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com