Stainless steel four-way reversing valve main valve with integrated valve seat for air conditioner and machining method

A four-way reversing valve, stainless steel technology, applied in the field of reversing valves, can solve the problems of easy deformation of the valve port surface, weak welding, complex processing technology, etc., to achieve improved welding strength and reduced processing complexity , The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

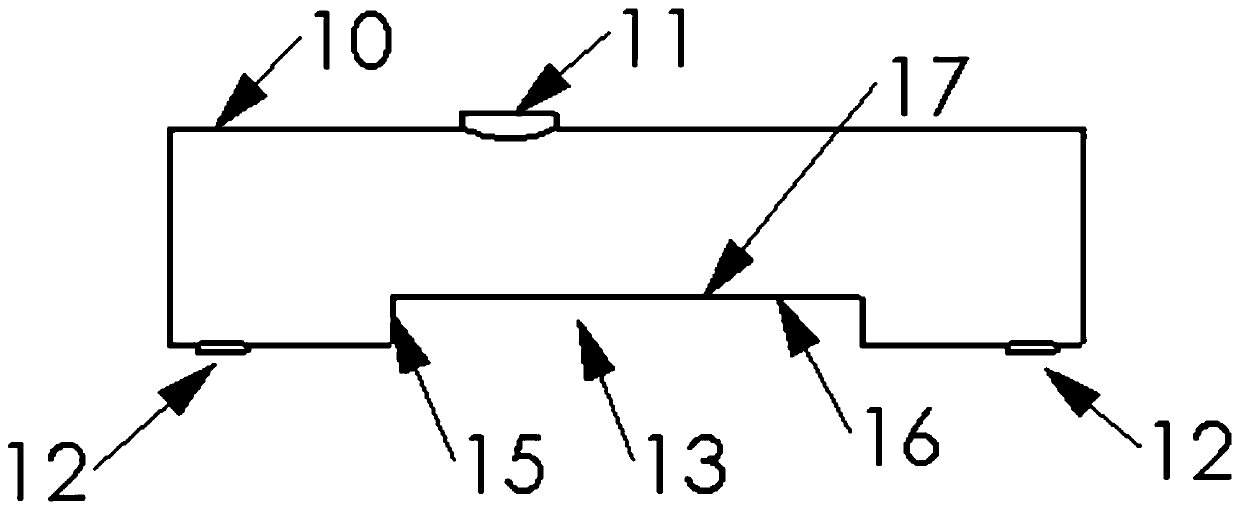

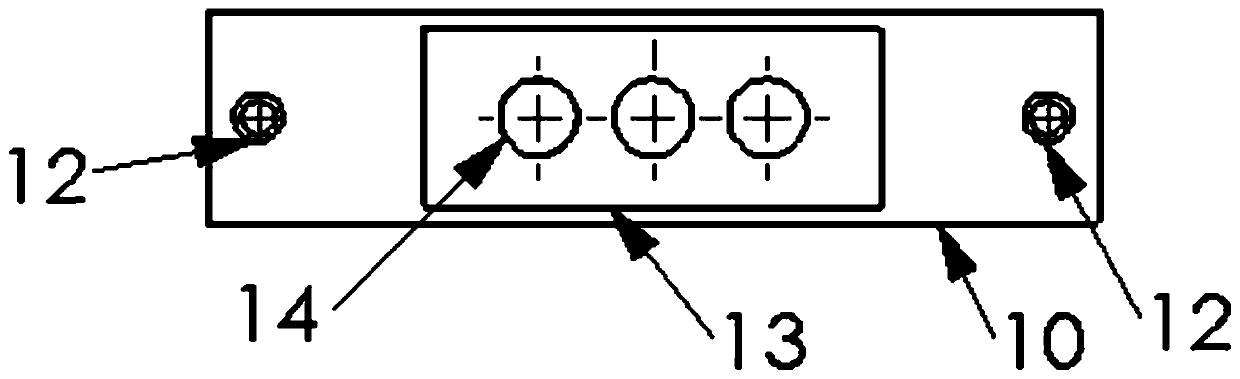

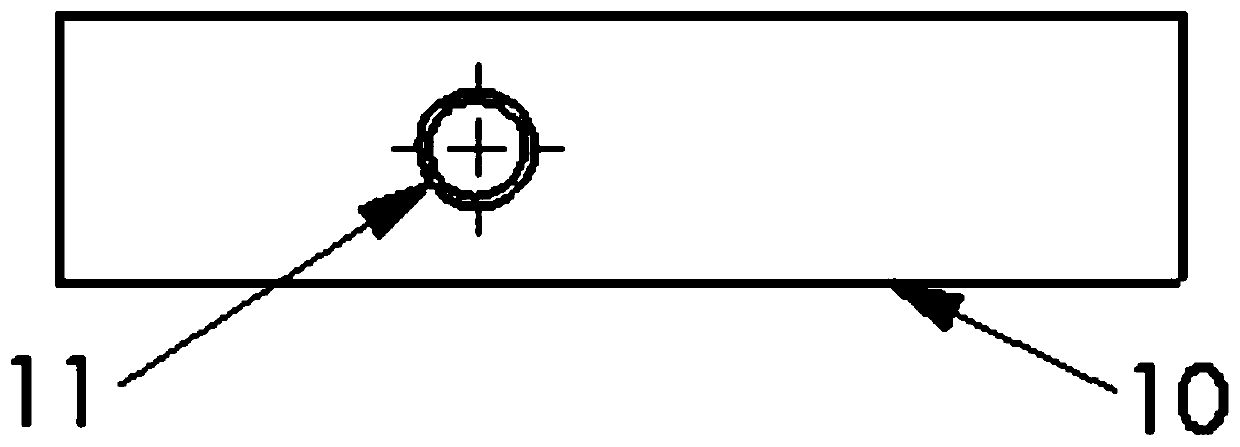

[0055] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 13, and 14, the present invention includes a tubular valve body 10, a D connecting pipe 30 is directly welded on the valve body 10, and also includes a connection fixed on the valve body 10 Seat 20, the parallel E connecting pipe 41, S connecting pipe 42, and C connecting pipe 43 are welded on the connecting seat 20, the middle part of the valve body 10 is concaved to form a valve seat 13, and the left and right sides of the valve seat 13 are connected to the The valve body 10 is disconnected to form an arched edge 15; the concave valve seat 13 forms a raised platform in the inner cavity of the valve body 10, and the top surface of the platform is the valve port surface 17 matched with the slider in the valve body, concave The connecting seat 20 is embedded in the valve seat 13, and the left and right sides of the connecting seat 20 cover the gap formed after the valve seat 13 and the valve body 10 are disconnected. The valve p...

Embodiment 2

[0087] The same place as Embodiment 1 will not be described in detail, the difference is: as Figure 9 , 10 , 11, 12, 15, and 16, the cross section of the connecting seat 20 is rectangular. The rectangular connection seat 20 is more convenient to process, which is beneficial to improve the processing accuracy and reduce the processing cost. On the premise of ensuring the reliability of welding, it is more convenient to use the connecting seat 20 for processing. The height of the connecting seat 20 is greater than or equal to the concave depth of the valve seat 13 to realize reliable sealing welding between the connecting seat and the valve body 10 .

[0088] After the above-mentioned improvement to the current technology, the production cost can be greatly reduced, and the production efficiency can be increased by 3 times at the same time. Has great economic value.

[0089] above Figure 1-16 The main valve and processing method of the stainless steel four-way reversing v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com