Vacuum pump with function of performance degradation early warning and application of vacuum pump to oiling machine

A technology of vacuum pump and performance, applied in the direction of pump, pump control, mechanical equipment, etc., can solve the problems of refueling gun jumping in advance, increasing installation gap, affecting normal adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

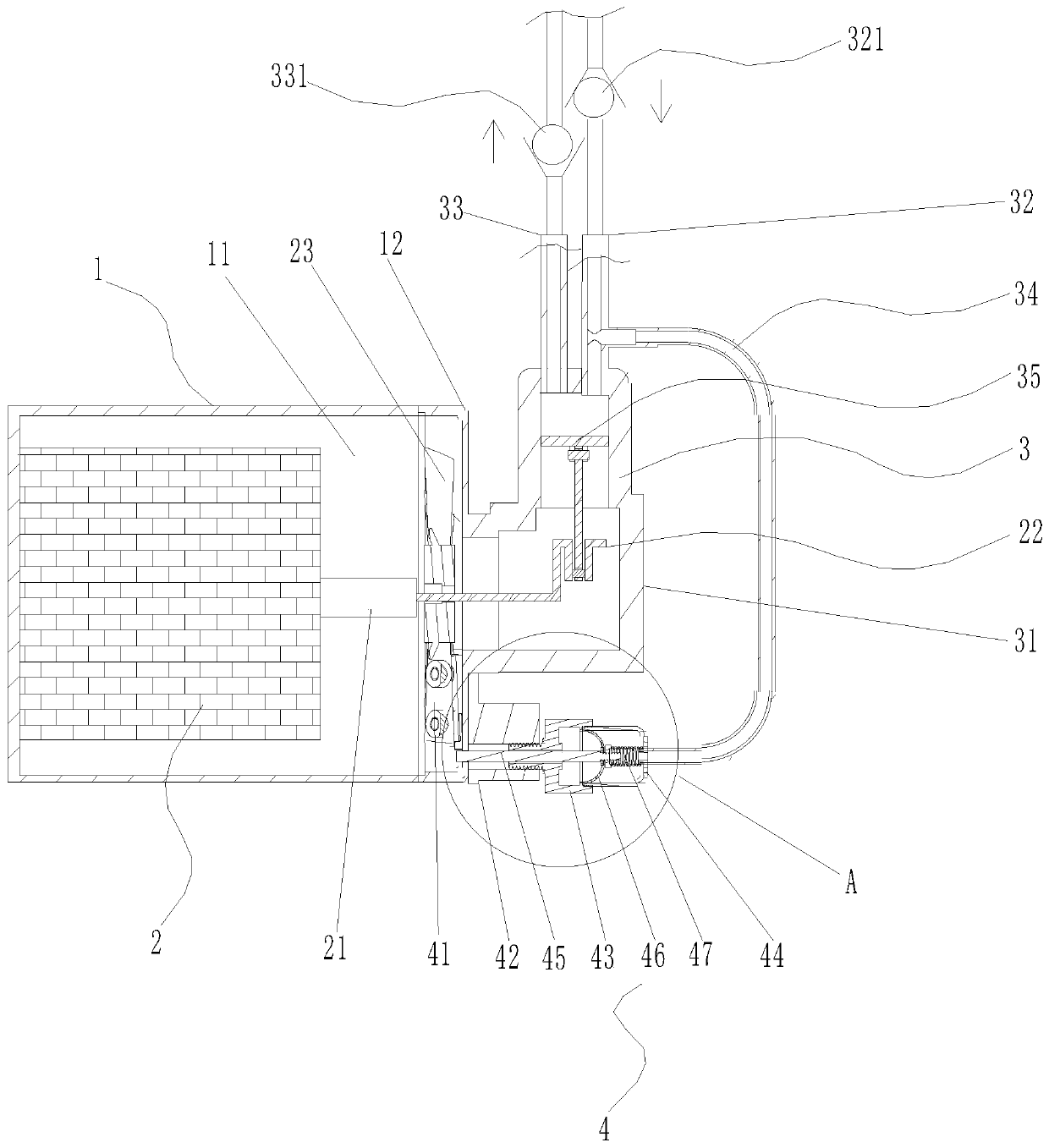

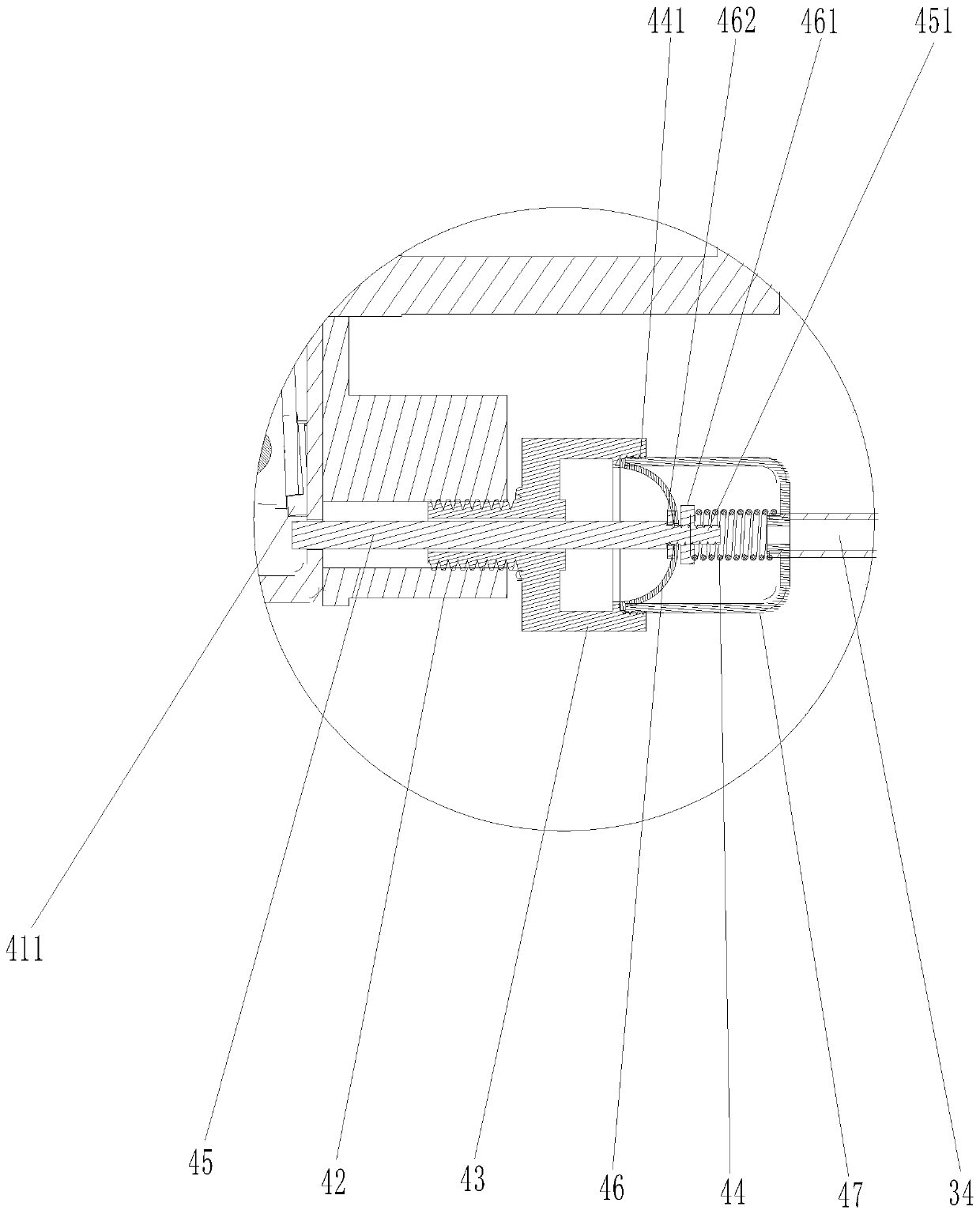

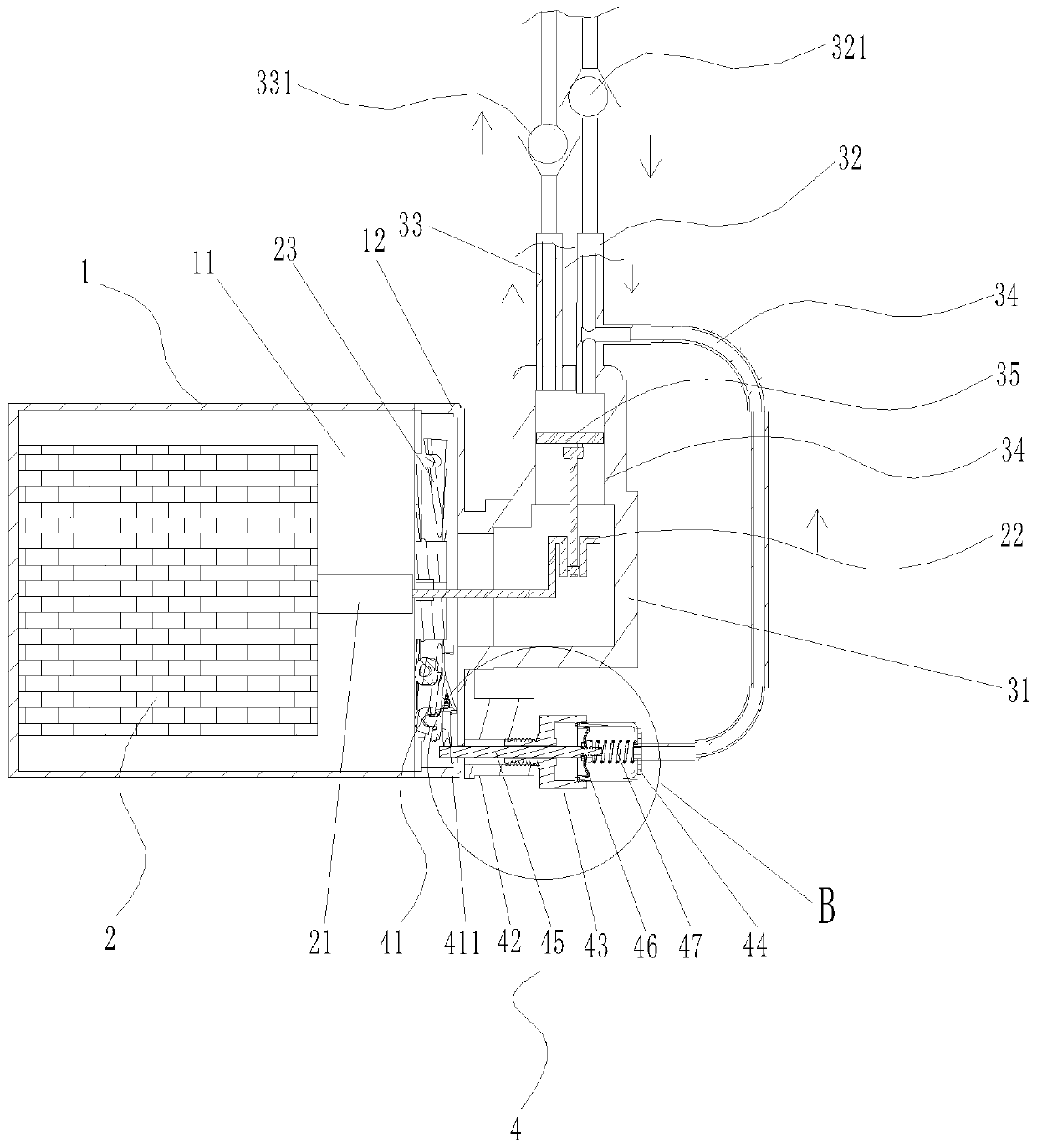

[0060] Such as Figure 1 to Figure 11 As shown in one of them, the present invention has a vacuum pump with early warning of performance degradation, including:

[0061] The casing 1 is a cylindrical shell structure with one end open;

[0062] The motor 2 is fixed in the casing 1, and its driving end has a rotating shaft 21 and the rotating shaft 21 extends along the open end of the casing 1;

[0063] Crankshaft 22, one end is a straight end and the end is fixedly connected with the rotating shaft 21 of the motor 2, and the other end is an eccentric end;

[0064] Fan blades 23 are even-numbered and fixedly connected to the straight end of the crankshaft 22 in a circular array;

[0065] The sub-housing 12 is fixed on the open end of the casing 1 and encapsulates the fan blade 23 and the motor 2 in the casing 1. The sub-housing 12 is provided with an avoidance through hole for the other end of the crankshaft 22 to pass through;

[0066] The negative pressure housing 3 is a cy...

Embodiment 2

[0084] Such as Figure 1 to Figure 15As shown in one, this embodiment is based on the structure of the vacuum pump with performance attenuation early warning in the above-mentioned embodiment 1. This embodiment also provides an early warning and troubleshooting device for oil and gas recovery vacuum pumps, which is installed in the refueling system. The refueling system Including oil tank 9, fuel dispenser 8, refueling gun 6, transmission pipeline 7 (including oil delivery pipe 71 and oil vapor recovery pipe 72); said oil tank 9 is sequentially connected with fuel dispenser and refueling gun through oil delivery pipe 71, said The oil vapor recovery pipe 72 is arranged in parallel with the oil delivery pipe 71 and the oil vapor recovery pipe 72 is connected with the refueling gun, the refueling machine and the oil tank 9 in sequence and is used to recover the oil and gas overflowed when the refueling gun is refueled. This embodiment includes the above-mentioned performance atten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com