Fuel injection valve assembly

A fuel injection valve and component technology, which is applied in the field of high-pressure common rail fuel injection, can solve the problems of limited working pressure of the injector, increased leakage risk of the contact surface, and high difficulty in manufacturing and processing, so as to reduce the opening delay time and improve the service life. , The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

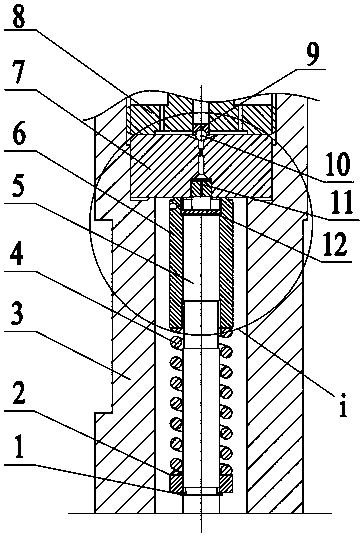

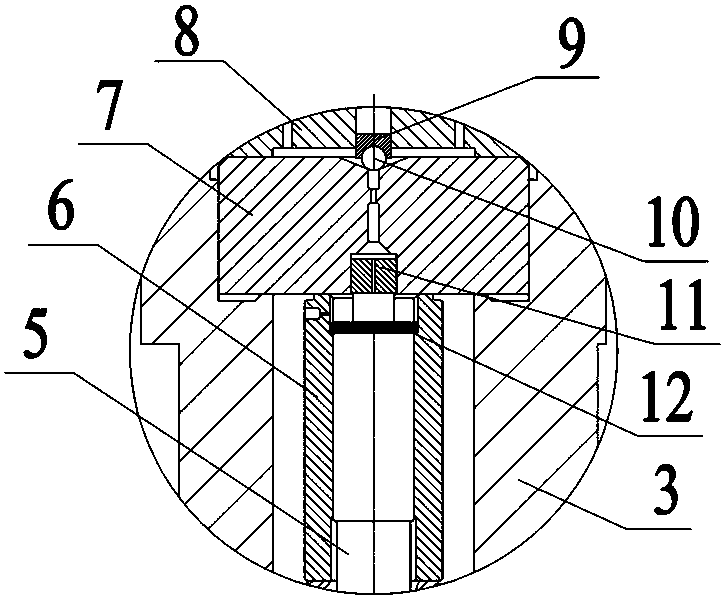

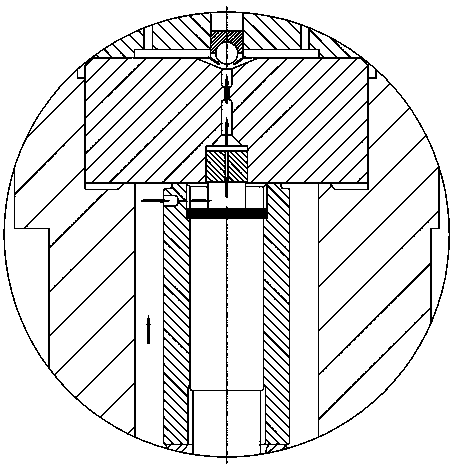

[0029] Example 1, please combine Figure 1 to Figure 3 As shown, the fuel injection valve components involved in this embodiment, such as figure 1 As shown, it includes a control plunger 5, a valve sleeve 6, an orifice 7 and a fastening valve seat 8. The fastening valve seat 8 and the injector body 3 are fixed by threaded connection, and the orifice plate 7 is fixed to the injector body 3. Inside, the valve sleeve 6 is sleeved on the outer circumference of the control plunger 5 to cooperate with the control plunger 5 , and the gap between the valve sleeve 6 and the control plunger 5 is between 0.008mm and 0.012mm. The valve sleeve spring 4 acts on the lower end surface of the valve sleeve 6, and the upper end surface of the valve sleeve 6 abuts against the lower end surface of the orifice plate 7. At this time, the control plunger 5, the valve sleeve 6 and the orifice plate 7 form a control cavity. The side wall of the valve sleeve 6 is provided with an oil inlet hole commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com