Gas extrusion sealing device of tube-sinking cast-in-place pile machine

A technology of immersed tube grouting piles and sealing devices, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve problems such as unsatisfactory use effects, aging gas valve structures, and unstable performance, achieving high fullness and ensuring Density, the effect of avoiding repeated reshaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

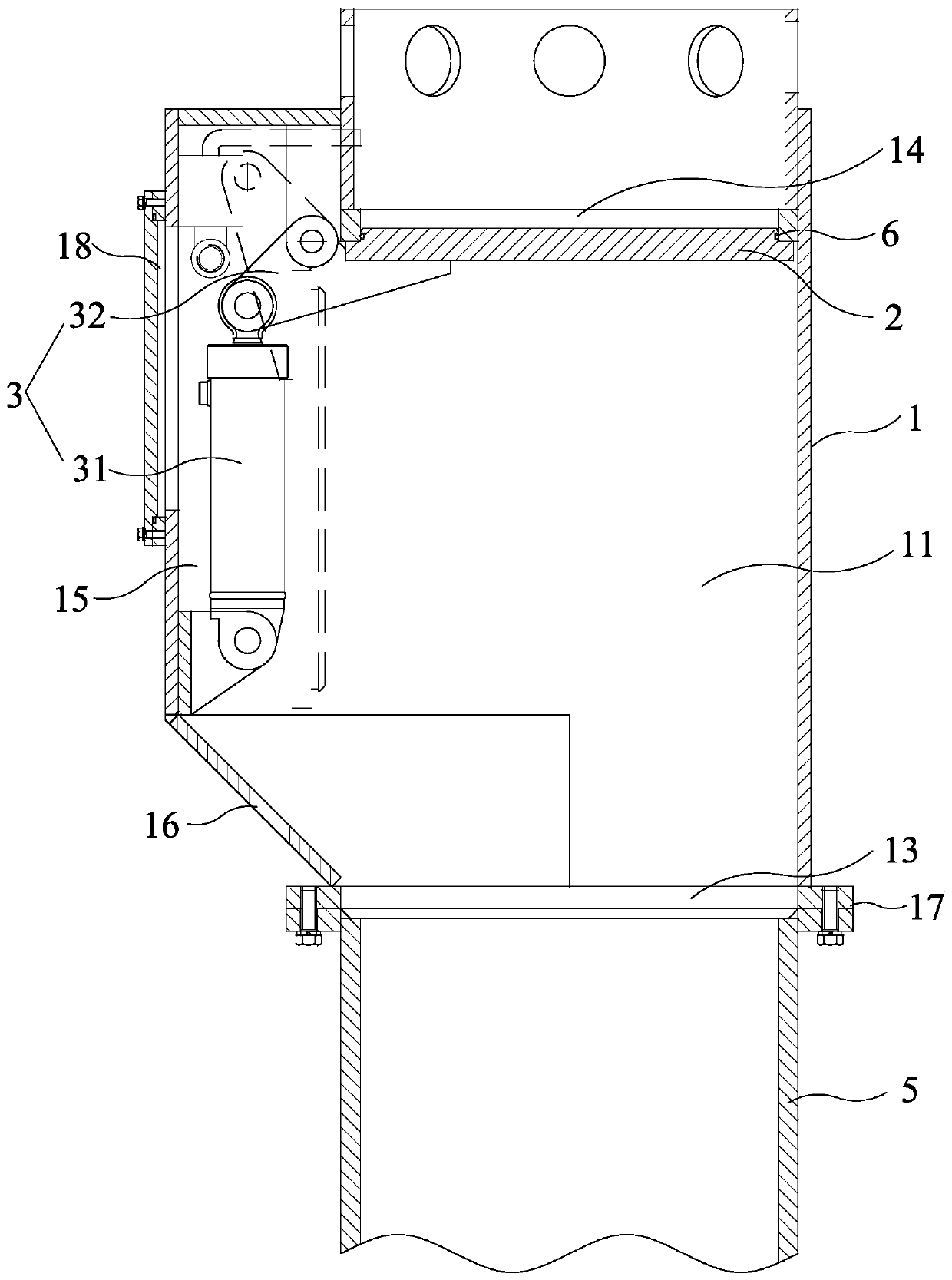

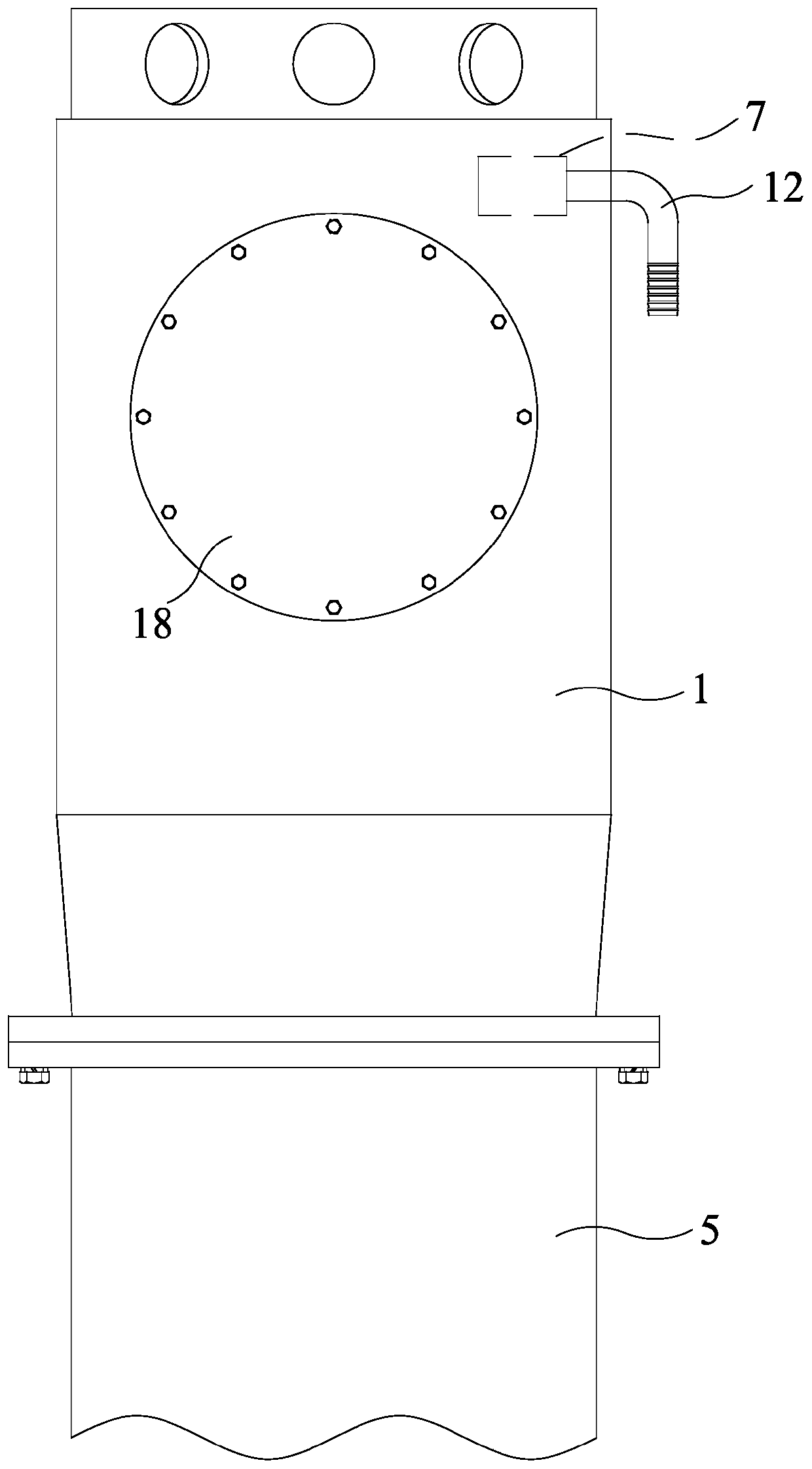

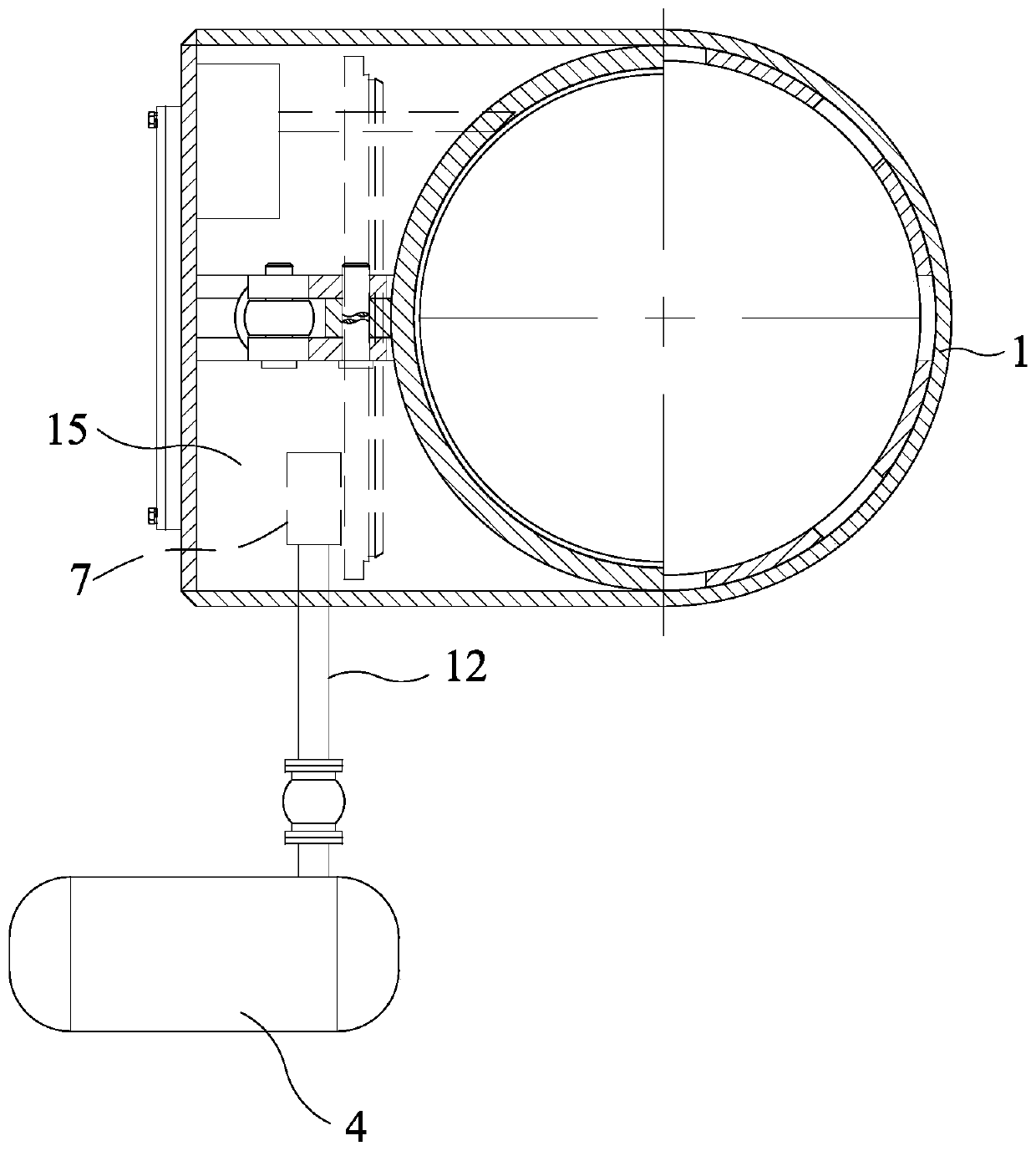

[0023] The invention provides a gas push sealing device for an immersed tube grouting pile machine, please refer to figure 1 , including a valve body 1, a cover plate 2, a control mechanism 3 and a gas booster mechanism 4, the valve body 1 is provided with a valve cavity 11 inside, and the valve cavity 11 is provided with an air intake passage 12, such as figure 2 and image 3 As shown, the air intake channel 12 communicates with the gas booster mechanism 4 through a pipeline, and an interface 13 is provided below the valve cavity 11, and the interface 13 is used for sealing connection with the construction steel pipe 5, and a feed inlet is provided above the valve cavity 11 14. The cover plate 2 is placed in the valve cavity 11, and is rotated to be installed on the feed port 14, and the feed port 14 can be used as a passage for feeding an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com