Silicon powder composition, method, reactor and device for producing hydrogen

A technology of reaction device and composition, applied in the field of silicon powder composition, to achieve the effect of improving practicability, stable reaction, stable and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

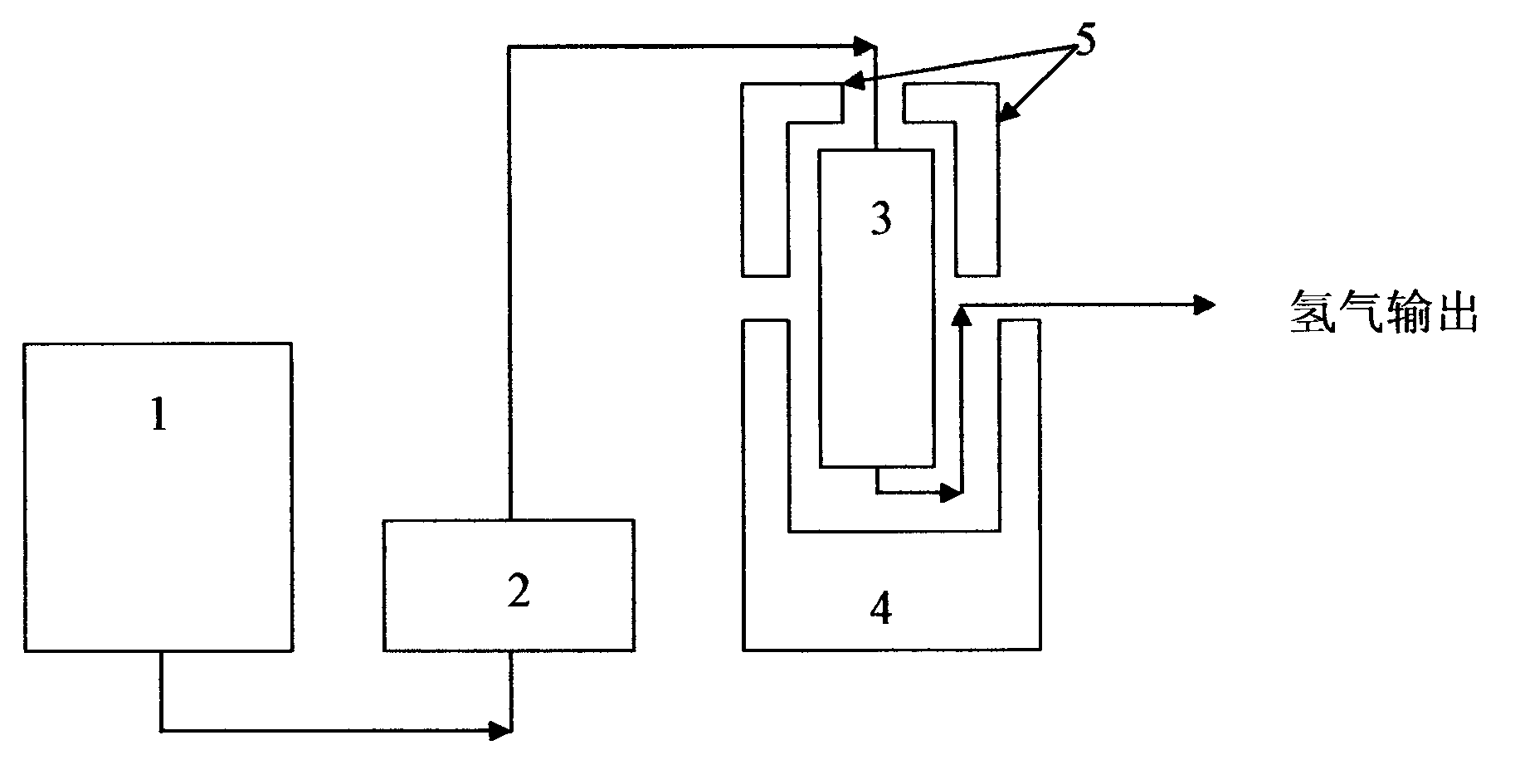

Method used

Image

Examples

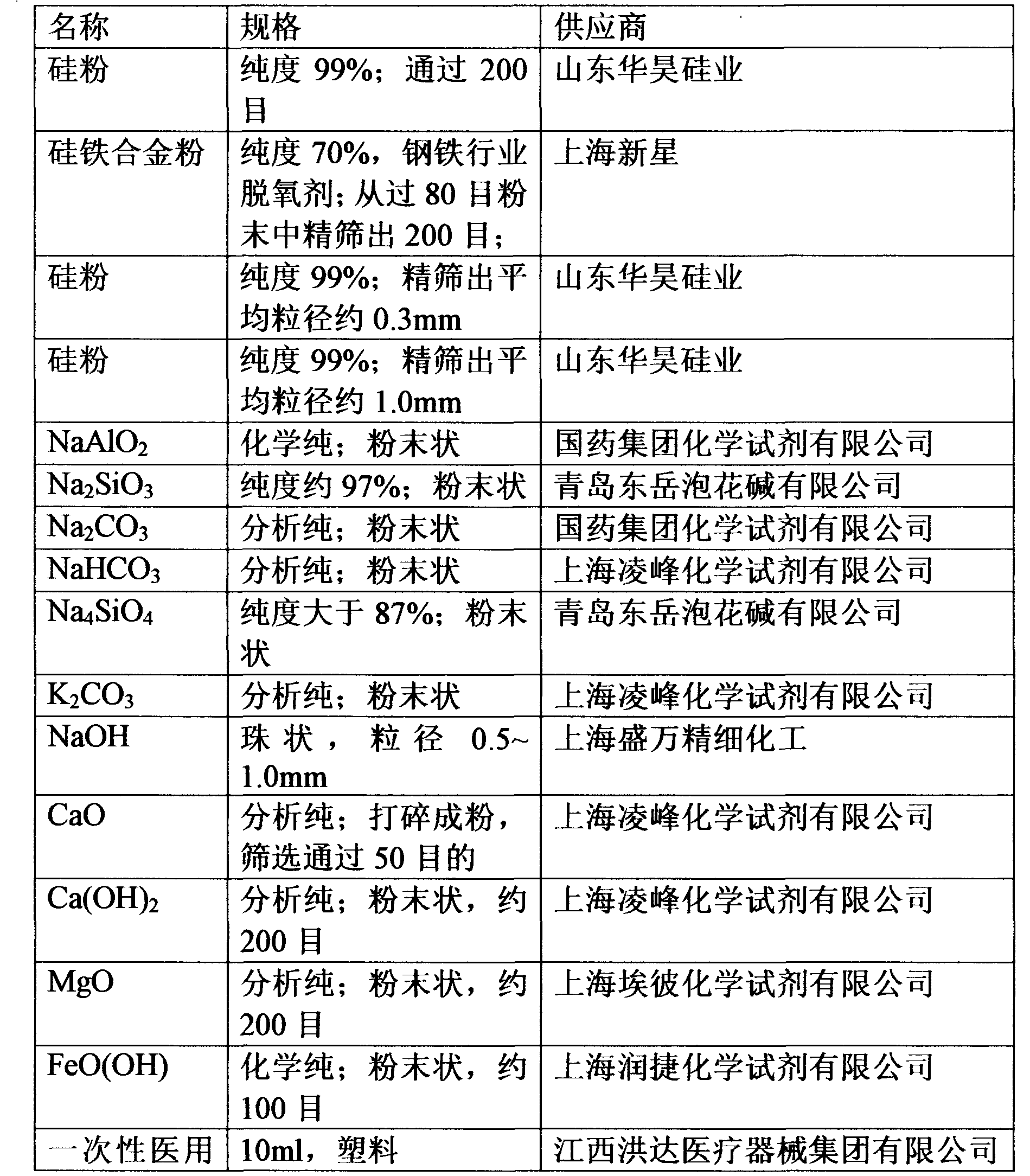

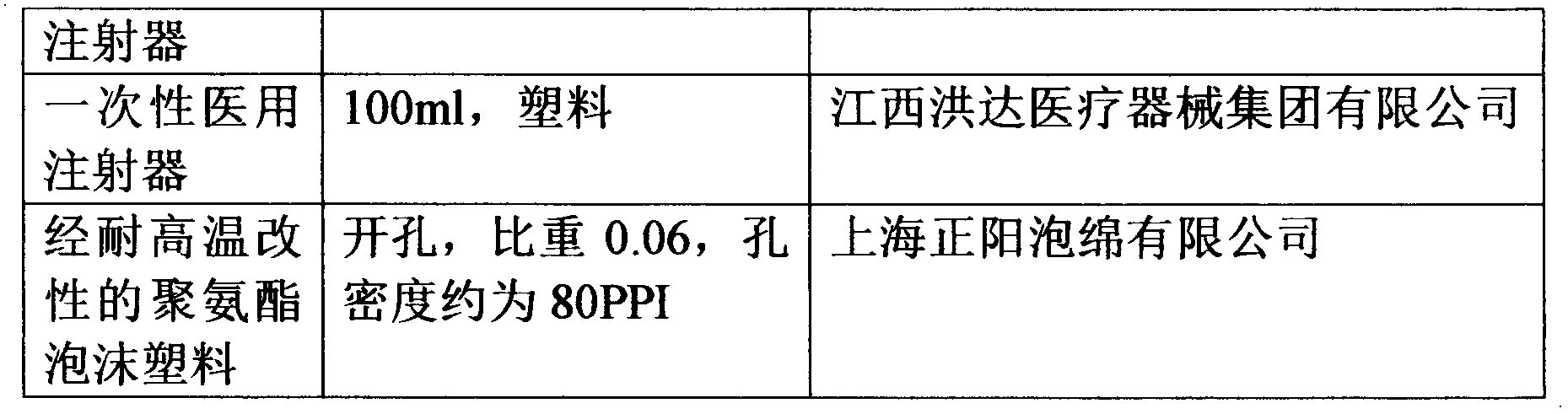

Embodiment 1

[0058] 1.05g silicon powder (about 3 / 80MOL), 2.1g CaO (about 3 / 80MOL), 0.5g NaAlO 2 After uniform mixing, a 10ml syringe is filled with a scale indicating that the volume of the composition is approximately 4.5cc.

[0059] The heater was used for the first 15 minutes, after which the heater was removed and an insulating cover was used instead.

[0060] The hydrogen production is recorded every 30 minutes, which are 130cc\160cc\210cc\220cc\210cc\210cc\180cc\130cc in sequence. At this time, the machine stops due to a significant drop in speed.

[0061] The cumulative hydrogen production is 1450cc, and the theoretically calculated reaction adequacy is 86.3%.

Embodiment 2

[0063] 1.05g silicon powder (about 3 / 80MOL), 2.1g CaO (about 3 / 80MOL), 0.5g Na 2 SiO 3 After uniform mixing, a 10ml syringe is filled with a scale indicating that the volume of the composition is approximately 4.0cc.

[0064] The heater was used for the first 15 minutes, after which the heater was removed and an insulating cover was used instead.

[0065] The hydrogen production volume is recorded every 30 minutes, which is 80cc\140cc\220cc\230cc\230cc\180cc\200cc\130cc in sequence. At this time, the machine stops due to a significant drop in speed.

[0066] The cumulative hydrogen production is 1410cc, and the theoretically calculated reaction adequacy is 83.9%.

Embodiment 3

[0068] 1.05g silicon powder (about 3 / 80MOL), 2.1g CaO (about 3 / 80MOL), 0.5g Na 2 CO 3 After uniform mixing, a 10ml syringe is filled with a scale indicating that the volume of the composition is approximately 4.0cc.

[0069] The heater was used for the first 15 minutes, after which the heater was removed and an insulating cover was used instead.

[0070] The hydrogen production volume is recorded every 30 minutes, which is 80cc\160cc\240cc\240cc\240cc\220cc\190cc\70cc in sequence. At this time, the machine stops due to a significant drop in speed.

[0071] The cumulative hydrogen production is 1440cc, and the theoretically calculated reaction adequacy is 85.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com