A kind of flame-retardant and antibacterial nylon wig fiber and preparation method thereof

A wig and fiber technology, applied in the field of flame-retardant and antibacterial nylon wig fiber and its preparation, can solve the problems of limited mechanical strength and flexibility, lack of research and production, complex processing technology, etc., achieve good smoothness and gloss, and significantly inhibit bacteria effect, the effect of increasing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

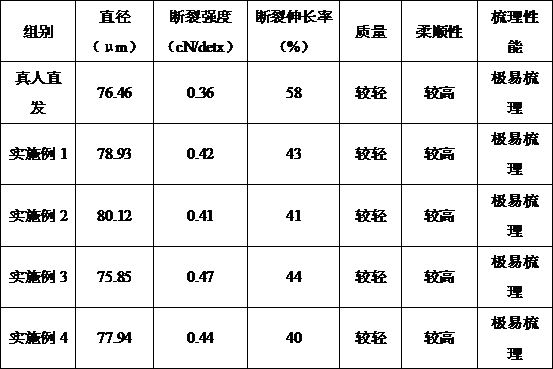

Examples

Embodiment 1

[0026] Modified nylon 66 is prepared according to the following steps:

[0027] Hexamethylenediamine and adipic acid with a weight ratio of 48% were respectively added to the polymerization reactor, and a nitrogen-containing phosphorus flame retardant with a weight ratio of 4% was weighed and added to the reactor. The reaction system is heated at 220-230° C. and 1.25-1.35 MPa for 2.5-3 hours. Then slowly increase the temperature to 260°C within 2 hours, maintain the system at 260°C and continuously exhaust and reduce the pressure, reduce the system to 2.4kPa at a uniform speed within 6 hours, keep the system at 260°C and 2.4kPa for 2 hours, then Cool in a cold water tank and pelletize to obtain modified nylon 66 masterbatch with a viscosity of 3.2-3.3.

[0028] The nitrogen-containing phosphorus flame retardant is: one or more of melamine cyanurate, melamine phosphate, melamine pyrophosphate or melamine polyphosphate.

Embodiment 2

[0030] A flame-retardant antibacterial nylon wig fiber, comprising the following steps:

[0031] (1) Percentage by weight: 85% of raw material modified nylon 66, 5% of flame retardant, 2% of synergistic flame retardant, 5% of antibacterial agent, 1% of dyeing agent, 1% of auxiliary additive, and 1% of dispersant ;

[0032] The modified nylon 66 is prepared from Example 1; the flame retardant is brominated epoxy resin; the synergistic flame retardant is antimony trioxide and silicon stannate, with a weight ratio of 1:2; The antibacterial agent is a quaternary ammonium salt antibacterial agent, chitosan and nano-silver antibacterial agent, and the weight ratio is 6:9:1; the additive is nano-calcium carbonate and silicon dioxide, and the mass ratio is 1:1; the dispersant Be the dispersed wax of molecular weight 200; Described dyeing agent is brown masterbatch;

[0033] (2) Dehumidify and dry the raw material at 95°C; the total time for dehumidifying and drying is 10 hours, and ...

Embodiment 3

[0040] A flame-retardant antibacterial nylon wig fiber, comprising the following steps:

[0041](1) Percentage by weight: 85% of raw material modified nylon 66, 5% of flame retardant, 2% of synergistic flame retardant, 5% of antibacterial agent, 1% of dyeing agent, 1% of auxiliary additive, and 1% of dispersant ;

[0042] The modified nylon 66 is prepared from Example 1; the flame retardant is brominated polystyrene; the synergistic flame retardant is antimony trioxide and silicon stannate, with a weight ratio of 1:2; Described antibacterial agent is quaternary ammonium salt antibacterial agent, chitosan and nano-silver antibacterial agent, weight ratio 6:9:1; Described additive is talcum powder; Described dispersant is the dispersing wax of molecular weight 200; Described dyeing agent It is brown masterbatch;

[0043] The remaining steps are the same as steps (2) to (8) in Example 2 to obtain antibacterial and flame-retardant nylon wig fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com