Slab continuous casting plain carbon steel LF desulphurization method

A technology of slab continuous casting and ordinary carbon steel, applied in the field of iron and steel metallurgy, can solve the problems of high consumption of slag for desulfurization, fluctuation of slab continuous casting production, uncontrolled LF cost, etc. The effect of improving pourability and stably controlling the state of inclusions in molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Processing steel grade Q235-DG.

[0025] For the treatment of steel grade Q235-DG, the basic requirements for steel grade composition: 0.13%-0.20%C, 0.10%-0.20%Mn, 0.10%-0.20%Si. The implementation of the slab continuous casting common carbon steel molten steel treatment method is as follows:

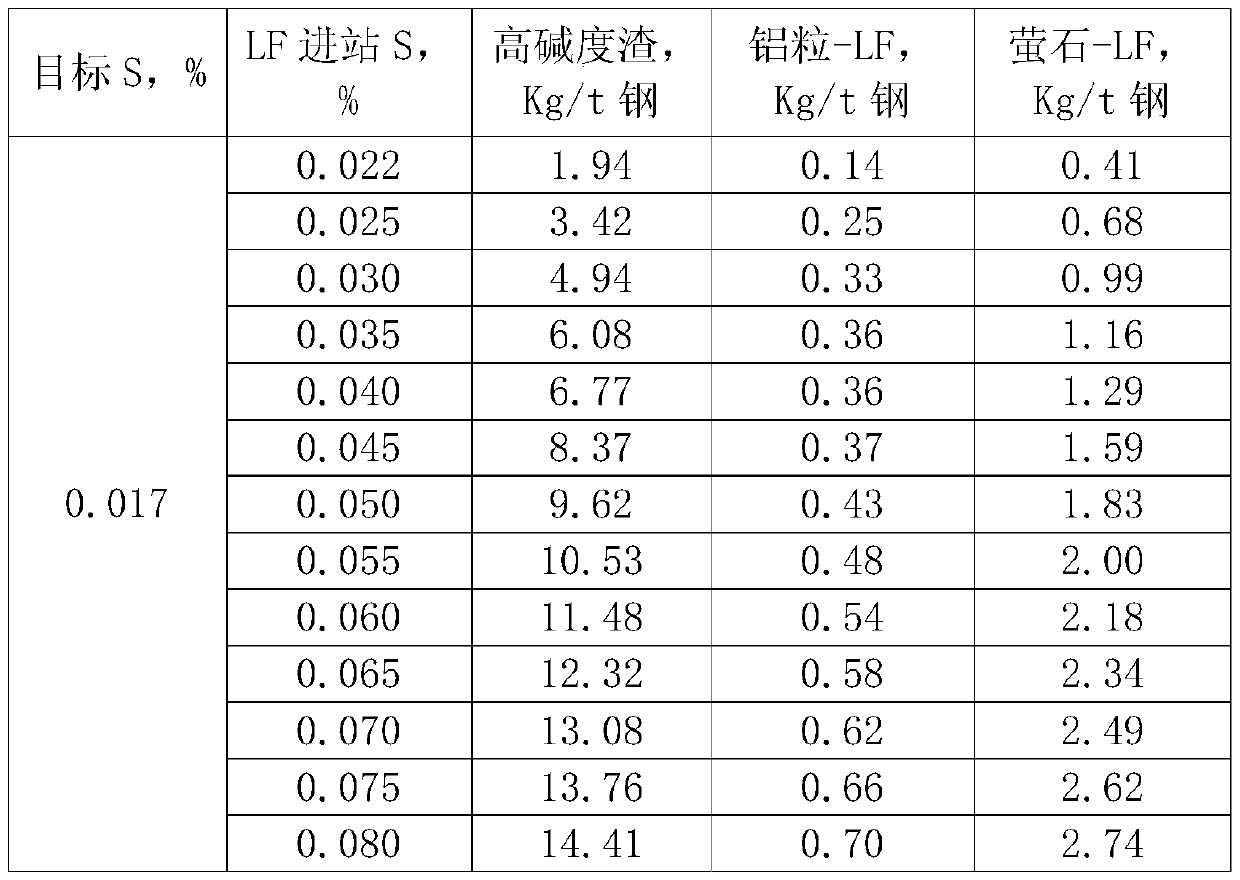

[0026] The amount of molten steel is 132.1 tons, the LF enters the station to determine the oxygen 46ppm, and the temperature is measured at 1569℃. The aluminum wire is fed 80g / t steel, measuring 96 meters (aluminum wire unit weight 0.2Kg / m), and the incoming sampling test composition is 0.14%C, 0.15 %Mn, 0.12%Si, 0.003%Al, S0.037%, add refining slag (CaO content> 65%, CaF 2 > 10%, other components are SiO 2 , Al 2 O 3 Etc.) 840Kg, aluminum particles 50Kg, fluorite 160Kg, heating time 19 minutes, fixed oxygen 6ppm, temperature measurement is 1587℃, outbound sampling test composition 0.15%C, 0.15%Mn, 0.13%Si, 0.008%Al, S0. 016%, good pourability during continuous casting.

Embodiment 2

[0028] Processing steel grade Q235 (G).

[0029] For the treatment of steel grade Q235 (G), the steel grade composition level requirements are: 0.13%-0.18% C, 0.15%-0.35% Mn, 0.10%-0.25% Si.

[0030] The implementation of the slab continuous casting common carbon steel molten steel treatment method is as follows:

[0031] The amount of molten steel is 130.9 tons, the LF enters the station to determine the oxygen concentration of 34ppm, and the temperature is measured at 1572℃. The incoming samples are tested for components of 0.15% C, 0.21% Mn, 0.12% Si, 0.003% Al, and S 0.051%. 65%, CaF 2 > 10%, other components are SiO 2 , Al 2 O 3 Etc.) 1280Kg, aluminum particles 70Kg, fluorite 250Kg, heating time 26 minutes, constant oxygen 5ppm, temperature measurement is 1585℃, outbound sampling test composition 0.16% C, 0.22% Mn, 0.13% Si, 0.009% Al, S0. 018%, good pourability during continuous casting.

[0032] The invention can ensure that under the premise of effectively improving the castab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com