3D printing method of bionic capillary network coated with multi-lamellar unit hydrogel

A capillary, 3D printing technology, applied in 3D culture, vascular endothelial cells, biochemical equipment and methods, etc., can solve the problems of poor mechanical strength, single shape, no environmental universality, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The 3D printing method of the biomimetic capillary network coated with multi-layer unit hydrogel, the preparation steps are as follows:

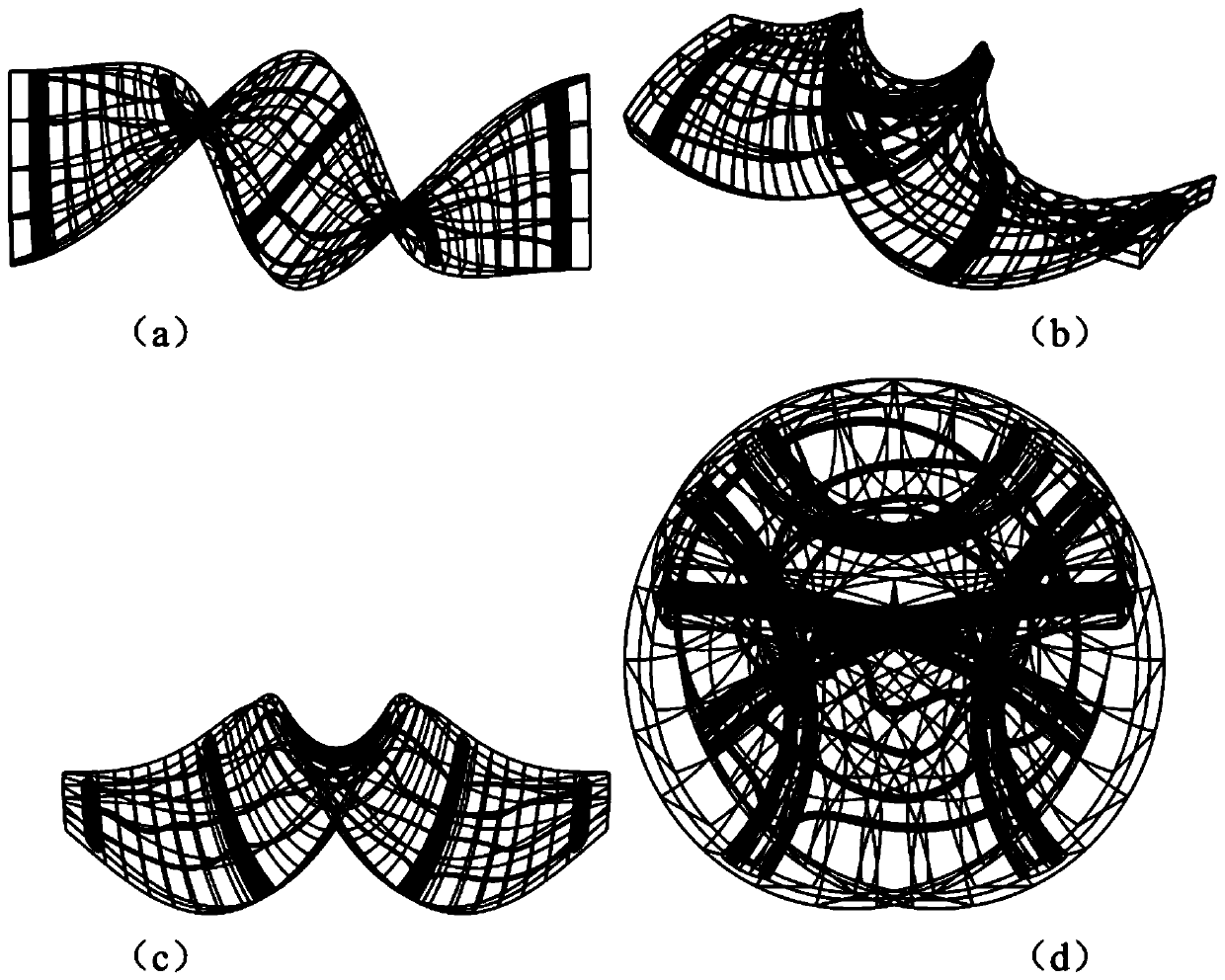

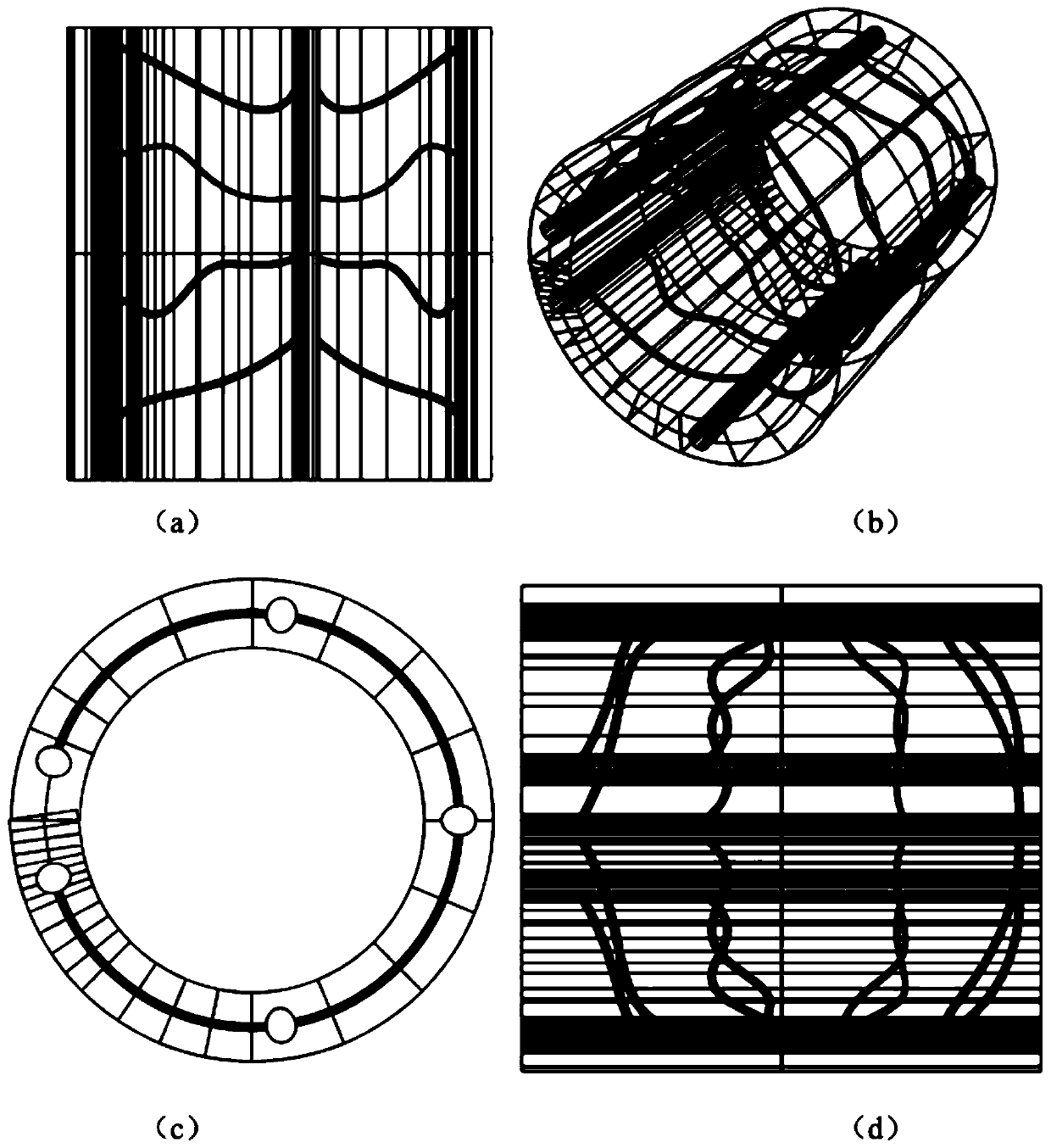

[0046] (1) Use 3D printing technology to prepare hydrogels containing vascular channels and growth factors in sheet units, specifically:

[0047] (1.1) To build a cylinder model, the specific process is: firstly dissolve gelatin in deionized water to prepare a 3D printing solution with a concentration of 10% (w / v), and then pour the 3D printing solution into the material tube of the 3D printing device , the constructed model is linearly printed layer by layer by the 3D printing device, and finally the printed product is freeze-dried, wherein the diameter of the cylinder is 0.05mm; the printing parameters are: injection pressure 1.0bar, printing speed 3.0mm / s, print nozzle diameter 0.26mm;

[0048] (1.2) Put the model obtained in step (1.1) into the injection molded container and then assemble it until all the cylinders are located a...

Embodiment 2

[0056] The 3D printing method of the biomimetic capillary network coated with multi-layer unit hydrogel, the preparation steps are as follows:

[0057] (1) Use 3D printing technology to prepare hydrogels containing vascular channels and growth factors in sheet units, specifically:

[0058] (1.1) Construct a composite model connected by two cylinders located at the same spatial level. The specific process is as follows: firstly, sodium alginate is dissolved in deionized water to prepare a 3D printing solution with a concentration of 20% (w / v). , and then pour the 3D printing solution into the material tube of the 3D printing device, and the 3D printing device will print the constructed model linearly layer by layer, and finally freeze-dry the printed product, wherein the diameter of the cylinder is 0.12 mm; printing parameters are: injection pressure 1.2bar, printing speed 3.8mm / s, printing nozzle diameter 0.45mm;

[0059] (1.2) Put the model obtained in step (1.1) into the in...

Embodiment 3

[0067] The 3D printing method of the biomimetic capillary network coated with multi-layer unit hydrogel, the preparation steps are as follows:

[0068] (1) Use 3D printing technology to prepare hydrogels containing vascular channels and growth factors in sheet units, specifically:

[0069] (1.1) Construct a composite model formed by connecting three cylinders located at the same spatial level. The specific process is as follows: firstly, chitosan is dissolved in 2% (w / w) glacial acetic acid to prepare a concentration of 20% ( w / v) 3D printing solution, and then pour the 3D printing solution into the material tube of the 3D printing device, and the constructed model is printed linearly layer by layer by the 3D printing device, and finally the printed product is freeze-dried, Among them, the diameter of the cylinder is 0.8mm; the printing parameters are: injection pressure 2.0bar, printing speed 5.2mm / s, printing nozzle diameter 0.8mm;

[0070] (1.2) Put the model obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com