Preparation and application of a high accumulation rate short-range nitrification composite bacteria-embedded bioactive filler

A technology of short-range nitrification and biological activity, which is applied in the field of preparation and application of high-accumulation rate short-range nitrification compound bacteria-embedded bioactive fillers, can solve the problems of high efficiency, production cost and production efficiency, and high technical requirements, and achieve reduction Small requirements, improved stability, and excellent hydraulic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

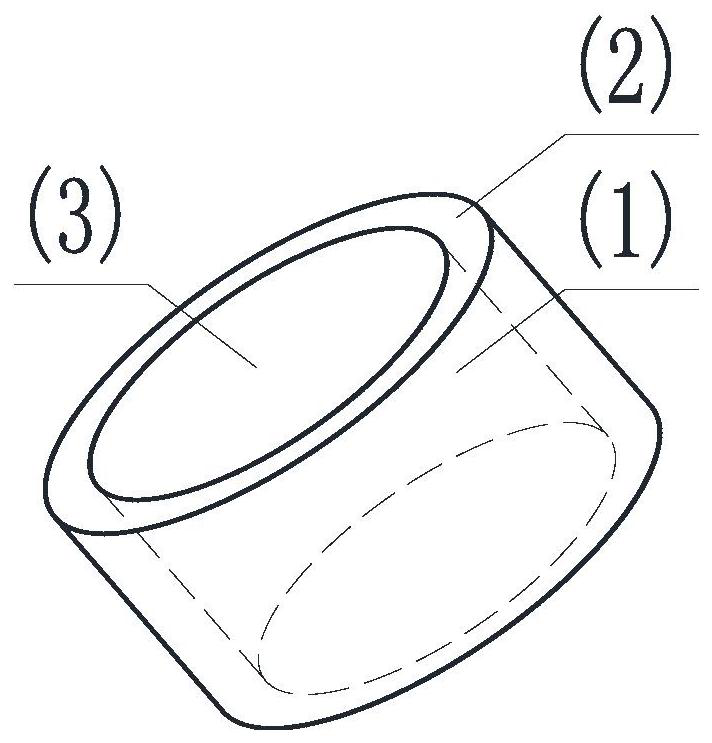

[0025] 1. Preparation of filler

[0026] Using the returned sludge from the urban sewage plant as the source of the bacteria, the short-range nitrifying bacteria were cultured in a directional way, and the short-path nitrifying bacteria suspension was concentrated by centrifugation and dehydration after enrichment and screening to obtain a culture of short-range nitrifying bacteria with a moisture content of 80%. There is a sewage treatment plant with nitrification ability to return sludge (water content 99%), the sediment is concentrated to a water content of 97%, and added to the bacterial culture tank, the volume is 1 / 3 of the effective volume of the culture tank; at a low temperature of 100r / min Under the condition of strong stirring, add ammonia nitrogen, the dosage of ammonia nitrogen is controlled to keep the concentration of free ammonia in the range of 16-18mg / L under a certain pH condition, and this state is maintained for 24 hours; then, start to introduce air for ae...

Embodiment 2

[0032] 1. short-range nitrifying bacteria culture culture and filler preparation (same as example 1)

[0033] 2. Application of short-range nitrification embedded active filler (municipal sewage)

[0034] The reactor continues the experiment of Example 1, the water temperature is 25±2°C, HRT=3h, and the pH is 6.8-7.3 (manual control is removed); the municipal sewage is used as the raw water, the reactor runs continuously for 24 hours a day, and the ammonia nitrogen in the reactor is measured every day Oxidation, nitrite and nitrate production. The test results of the effluent showed that the nitrite accumulation rate reached 91.6%, the ammonia nitrogen in the effluent was less than 1mg / L, and the biologically active filler reaction tank was continuously operated for nearly 4 months, and the biochemical effect was stable.

[0035] Effects of the present invention: 1. The wall thickness of the embedding filler is 1.5-2.5 mm. Under the premise of maintaining good permeability, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com