CaTiO3/CaO composite material as well as preparation method and application thereof

A composite material and mixed solution technology, applied in the field of new materials, can solve the problems of long labor time, large equipment loss, low efficiency, etc., and achieve the effects of avoiding strong alkali pollution, saving production costs, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

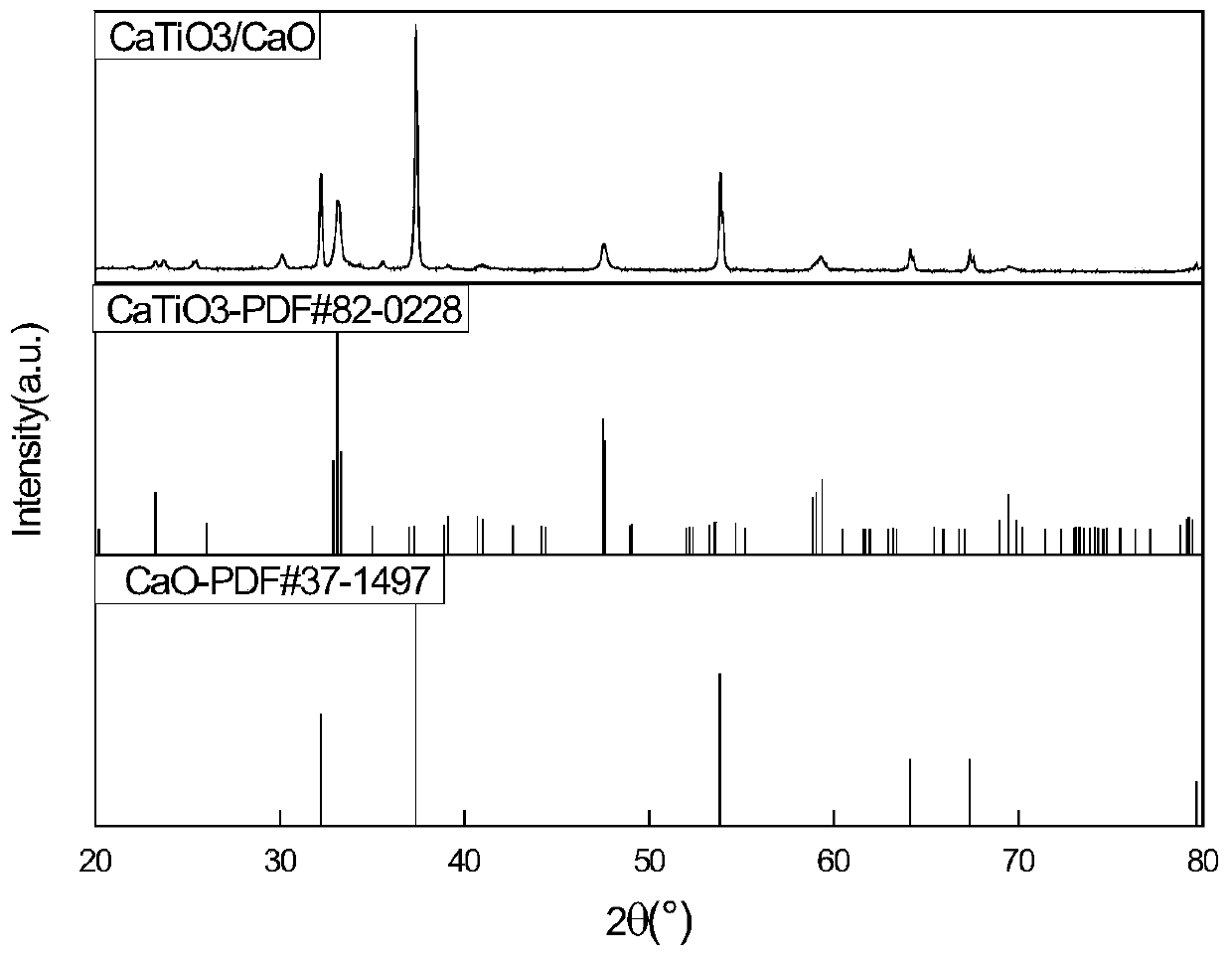

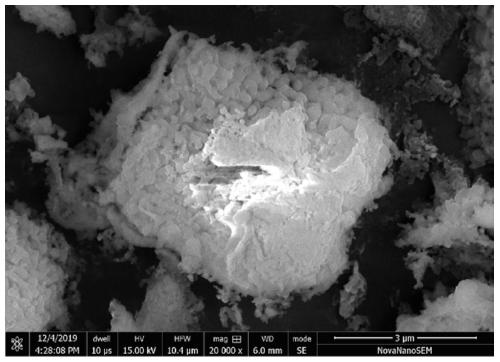

Image

Examples

Embodiment 1

[0039] The CaTiO of this embodiment 3 The preparation method of / CaO composite material, comprises the following steps:

[0040] (1) take by weighing the TiOSO of 0.8g 4 Mix it with 20mL of water, stir vigorously for 30min under the condition of ultrasonic power of 180W, and continue stirring at 30°C to obtain TiOSO 4 Solution A;

[0041](2) Weigh 0.5g of CaCO 3 Place in 15mL of water and stir ultrasonically for 30min at room temperature to obtain CaCO 3 Suspension B; wherein, the ultrasonic power is 180W;

[0042] (3) Weigh CO(NH 2 ) 2 Dissolve in 10mL water, stir evenly and let it stand to obtain transparent CO(NH 2 ) 2 Solution C;

[0043] (4) TiOSO in step (1) 4 Solution A was placed in a constant temperature magnetic stirrer, kept at a constant temperature of 30°C and stirred at a medium speed, and then the CaCO prepared in step (2) 3 Suspension B was slowly added to TiOSO 4 In solution A, stir for 2 hours, and obtain mixed solution D after the reaction; wherei...

Embodiment 2

[0051] The CaTiO of this embodiment 3 The preparation method of / CaO composite material, comprises the following steps:

[0052] (1) take by weighing the TiOSO that quality is 1.4g 4 Mix with 30mL of water, stir vigorously for 30min under ultrasonic power of 180W, then continue stirring at 30°C to obtain TiOSO 4 Solution A;

[0053] (2) Weigh 1g of CaCO 3 Place in 30mL of water and stir ultrasonically for 30min at room temperature to obtain CaCO 3 Suspension B; wherein, the ultrasonic power is 180W;

[0054] (3) Weigh 1g of CO(NH 2 ) 2 Dissolve in 20mL water, stir evenly and let it stand to obtain transparent CO(NH 2 ) 2 Solution C;

[0055] (4) TiOSO in step (1) 4 Solution A was placed in a constant temperature magnetic stirrer, kept at a constant temperature of 30°C and stirred at a medium speed, and then the CaCO prepared in step (2) 3 Suspension B was slowly added to TiOSO 4 In solution A, stir for 2 hours, and obtain mixed solution D after the reaction; wherein...

Embodiment 3

[0061] The CaTiO of this embodiment 3 The preparation method of / CaO composite material, comprises the following steps:

[0062] (1) take by weighing the TiOSO that quality is 0.85g 4 Mix with 20mL of deionized water, stir vigorously for 30min under the condition of ultrasonic power of 180W, and continue stirring at 25°C to obtain TiOSO 4 Solution A;

[0063] (2) Weigh 0.5g of CaCO 3 Placed in 15 mL of deionized water, stirred ultrasonically for 30 min at room temperature to obtain CaCO 3 Suspension B, wherein the ultrasonic power is 180W;

[0064] (3) Weigh CO(NH 2 ) 2 Dissolve in 12mL deionized water, stir evenly and let stand to obtain transparent CO(NH 2 ) 2 Solution C;

[0065] (4) TiOSO in step (1) 4 Solution A was placed in a constant temperature magnetic stirrer, kept at a constant temperature of 30°C and stirred at a medium speed, and then the CaCO prepared in step (2) 3 Suspension B was slowly added to TiOSO 4 In solution A, stir for 2 hours, and obtain mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com