A kind of electrolyte solution for secondary zinc-nickel battery and preparation method thereof

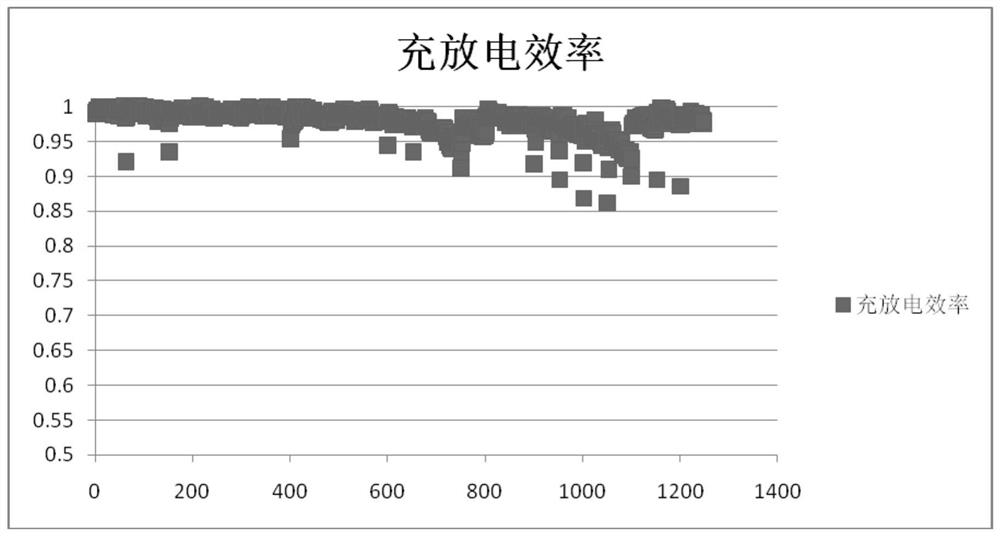

A technology of nickel battery and electrolyte, applied in the field of electrolyte for secondary zinc-nickel battery and its preparation, can solve the problems of rapid decrease of battery charge and discharge capacity, serious dendrite growth, and decrease of cycle performance, so as to improve the charge and discharge Cycle performance, reduced electrolyte deposition, high commercial value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Accurately weigh the following formula for subsequent use: 35w% alkali (technical grade potassium hydroxide), 2w% LiOH, 2w% boric acid, 0.1w% Al(OH) 3 , 10w% ZnO, 0.01w% SiO 2 , the balance is water;

[0029] 2. Weigh 500mL pure water into the beaker, turn on the electric ceramic furnace to heat, add LiOH and aluminum compound at one time, and turn on the stirring equipment;

[0030] 3. When the LiOH and aluminum compound to be added are basically dissolved, start to add alkali; and ensure that the temperature is not higher than 120°C;

[0031] 4. The alkali is added in 3 times, and the alkali added in the previous time is completely dissolved before each addition. After the first two additions of alkali, keep the temperature at 120°C and keep stirring to ensure the complete dissolution of LiOH and aluminum compounds. After the last two alkali additions, continue to stir until completely dissolved;

[0032] 5. After the above solution is clarified, add ZnO to the...

Embodiment 2

[0038] 1. Accurately weigh the following formula for subsequent use: 30w% alkali (technical grade sodium hydroxide), 2w% LiOH, 0.15% boric acid and / or borate, 0.1w% Al 2 Oh 3 , 15w% ZnO, 0.02% SiO 2 , the balance is pure water;

[0039] 2. Weigh 400mL pure water into the beaker, turn on the electric ceramic furnace to heat, add LiOH and aluminum compound at one time, and turn on the stirring equipment;

[0040] 3. When the added LiOH and aluminum compound are basically dissolved, start to add alkali. And ensure that the temperature shall not be higher than 130°C;

[0041] 4. The alkali is added in 5 times, and the alkali added in the previous time is completely dissolved before each addition. After the first two additions of alkali, keep the temperature at 130°C and keep stirring to ensure the complete dissolution of LiOH and aluminum compounds. After the last two alkali additions, continue to stir until completely dissolved;

[0042] 5. After the above solution is clari...

Embodiment 3

[0048] 1. Accurately weigh the following formula for subsequent use: 30w% alkali (technical grade potassium hydroxide), 2w% LiOH / lithium salt, 1% boric acid and / or borate, 1w% Al 2 Oh 3 , 15w% ZnO, 0.03% SiO 2 , the balance is pure water;

[0049] 2. Weigh 400mL pure water into the beaker, turn on the electric ceramic furnace to heat, add LiOH and aluminum compound at one time, and turn on the stirring equipment;

[0050] 3. When the added LiOH and aluminum compound are basically dissolved, start to add alkali. And ensure that the temperature shall not be higher than 130°C;

[0051] 4. The alkali is added in 4 times, and the alkali added in the previous time is completely dissolved before each addition. After the first two additions of alkali, keep the temperature at 130°C and keep stirring to ensure the complete dissolution of LiOH and aluminum compounds. After the last two alkali additions, continue to stir until completely dissolved;

[0052] 5. After the above soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com