chip pickup head

A pick-up head and chip technology, used in electrical components, conveyor objects, transportation and packaging, etc., can solve the problems of difficulty in accurately controlling the down pressure of the pick-up head, inability to control the rotation angle of the chip, and motor current fluctuations. The effect of low load and small fluctuation of in-cylinder air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a further elaboration of the present invention by specific embodiments:

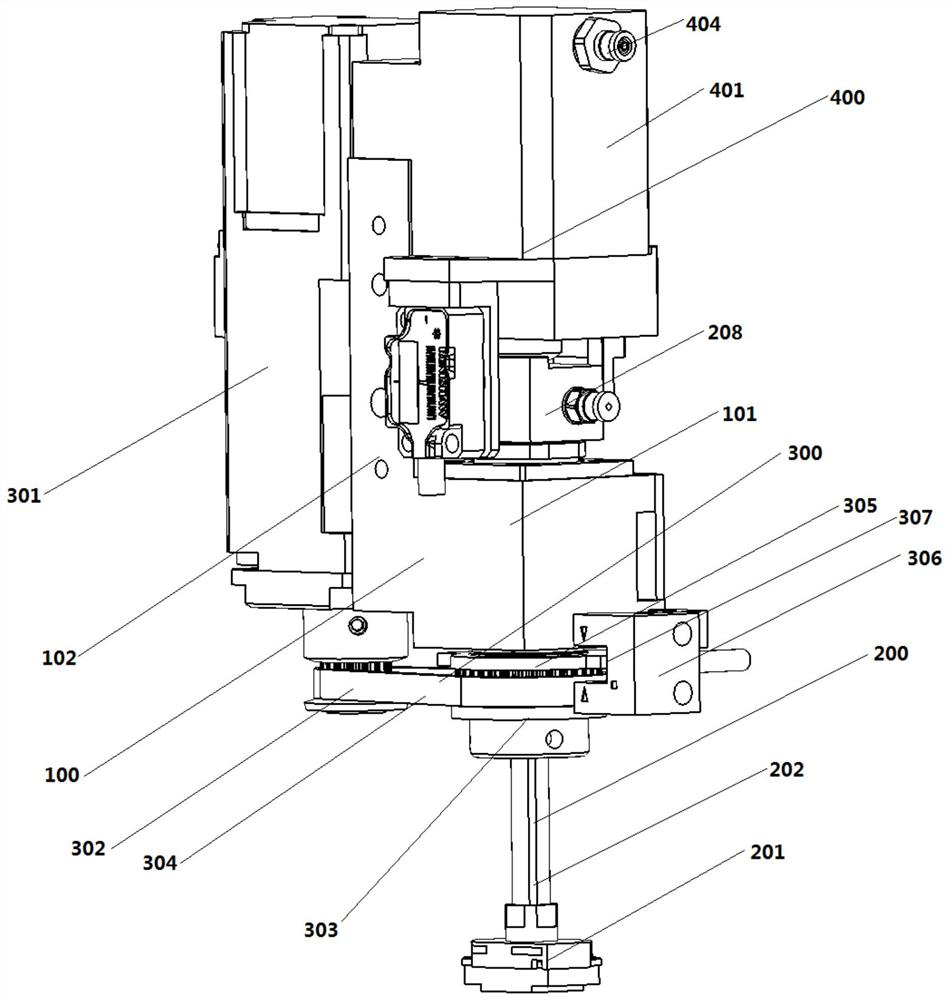

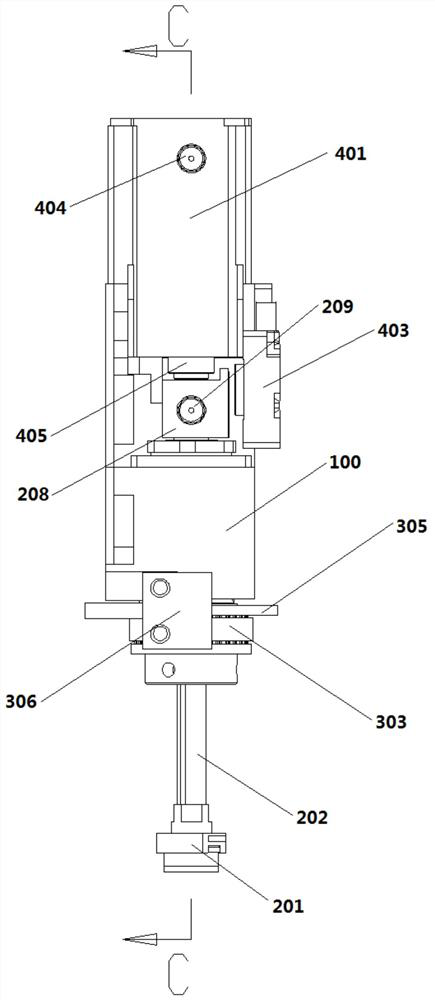

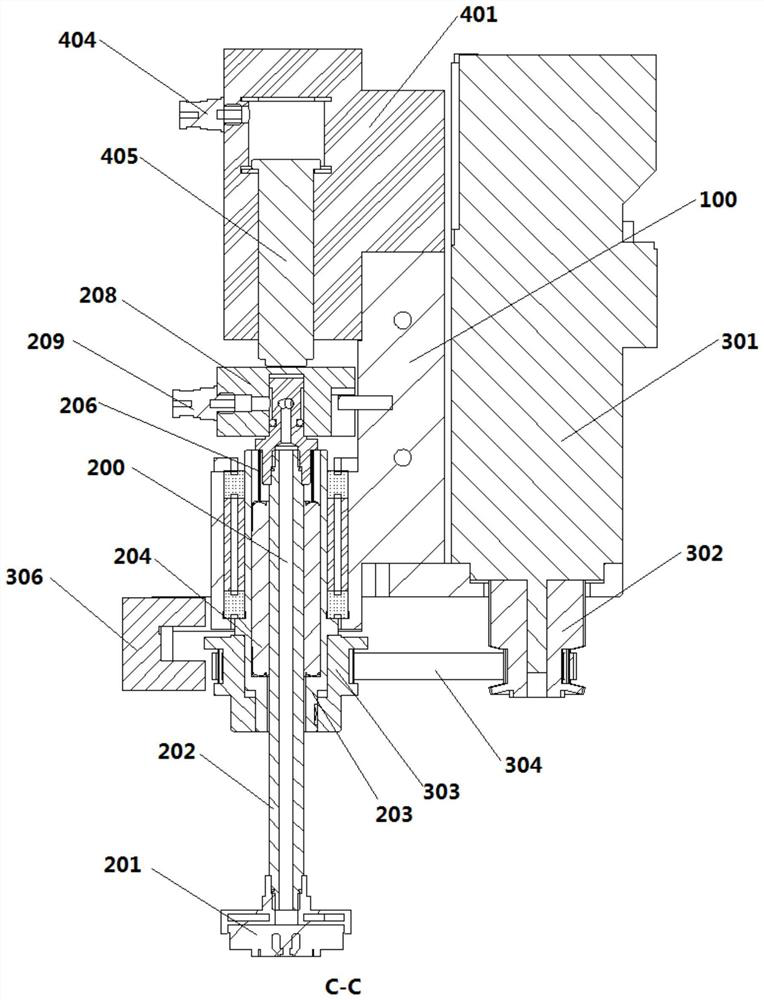

[0029] as Figure 1 、 Figure 2 and Figure 3 As shown, a chip suction head, comprising a base 100 and a vacuum tip 200 disposed on the base 100, respectively, a rotary drive device 300 and a lifting drive device 400.

[0030] as Figure 4 As shown, the base 100 includes a rectangular body mount 101 and a side mount 102 located vertically on the side of the main fixing seat 101. The main body fixing seat 101 is provided with a vertical through hole 103 through the main body fixing seat 101.

[0031] as Figure 5 As shown, the vacuum tip 200 includes a gas guide rod 202 permeated in the vertical through hole 103, and the air guide rod 202 extends vertical through hole 103 outside the bottom connected to the suction nozzle 201, and the air guide rod 202 extends the vertical through hole 103 outside the top connected to the suction device and supported between the air guide rod 202 and the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com