Superhard ball grinding tool

A sphere and tooling technology, applied in the field of superhard sphere grinding tooling, can solve problems such as limited grinding technology, and achieve the effects of good practicability, reasonable structure setting, and rapid pressure positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

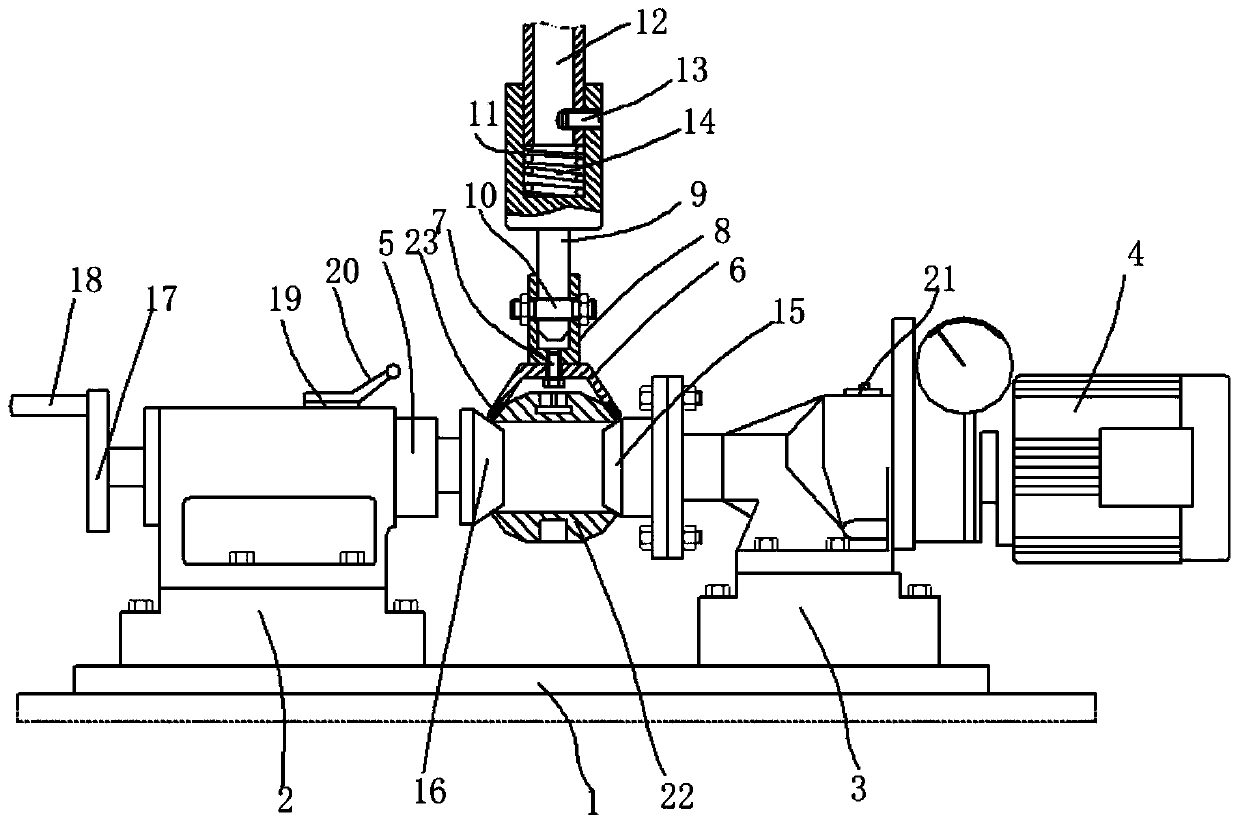

[0015] figure 1 A specific embodiment of the present invention is shown, wherein figure 1 It is a schematic diagram of the structure of the present invention.

[0016] see figure 1 , A superhard sphere grinding tool, comprising a machine tool 1, a positioning seat 2 is fixed on the machine tool, a motor seat 3 is also fixed on the machine tool, and a drive motor 4 is provided on the motor seat. The positioning seat is provided with a transverse screw hole (not shown, does not affect the understanding and realization of the skilled person), and a transverse screw 5 is provided in the transverse screw hole, and the transverse screw and the main shaft of the driving motor are in the same position. In a straight line, a radial drilling machine is fixed on the machine tool (this is a conventional structure in the prior art, so it is not described in detail), and it also includes a butterfly-shaped diamond wheel base 6, and the top center of the butterfly-shaped diamond wheel base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com