New cutting device for plastic processing

A cutting device and plastic technology, applied in metal processing and other directions, can solve the problems of increasing the workload of the staff, reducing the practicability of the cutting device, and unable to automatically cut plastics, etc., to ensure effectiveness and stability, good practicability, and structure. Set reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

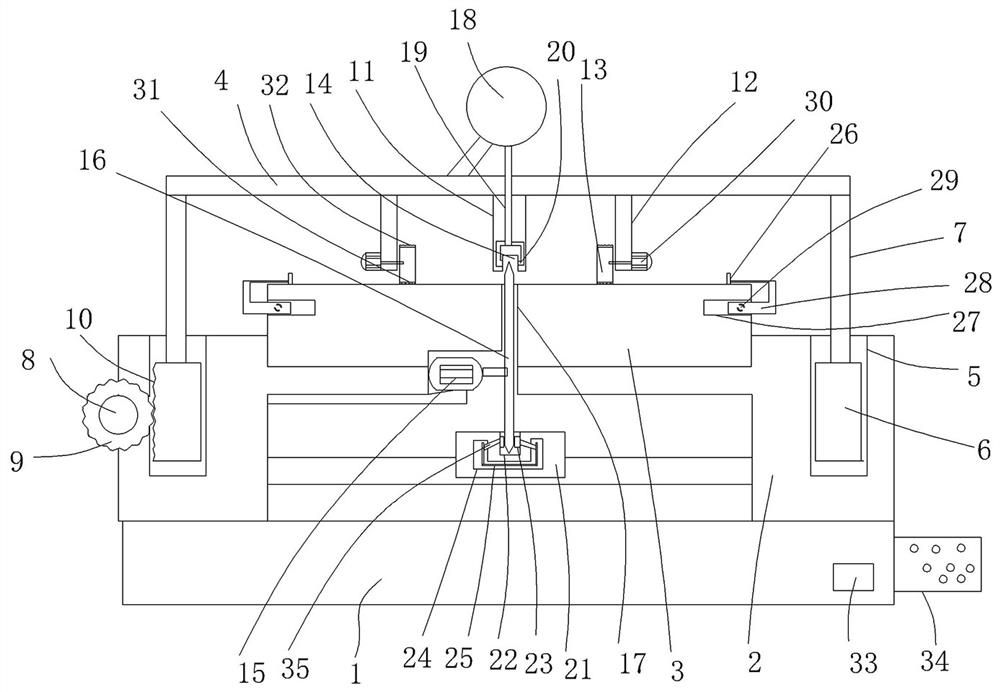

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a new type of cutting device for plastic processing, comprising a base 1, a support frame 2 arranged on the base, a cutting panel 3 is fixed on the top of the support frame, and a cutting panel 3 is fixed on the top of the cutting panel A bearing panel 4 is provided, the bearing panel is parallel to the cutting panel, two lifting cavities 5 are arranged on the top surface of the support frame, and the lifting cavities are arranged symmetrically with the cutting panel as the center, A lifting slider 6 is arranged in the lifting cavity, a support rib 7 is fixed between the top of the lifting slider and the bearing panel, and a control motor 8 is fixed on the side of the support frame. A drive gear 9 is fixed on the main shaft of the control motor, and a tooth groove 10 on the same vertical line is evenly fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com