Fixture adjustable steel structure cutting and processing device

A technology of cutting processing and fixtures, which is applied in the field of cutting and processing devices for steel structures with adjustable fixtures, can solve the problems of applicability and practicability limitations, affecting the quality of processing, affecting processing efficiency, etc., and achieve good practicability, guaranteed accuracy, and structural Set reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

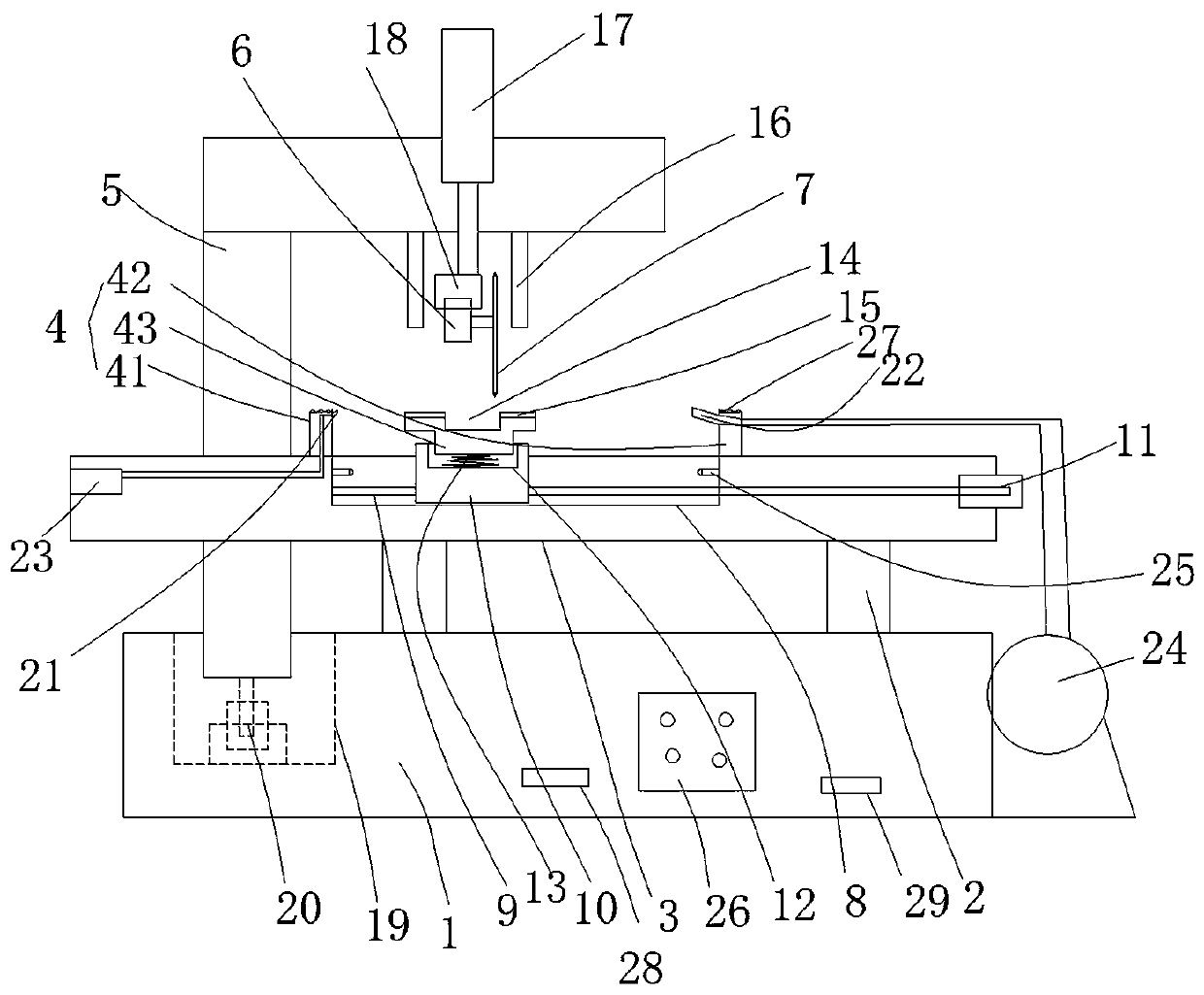

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a clamp adjustable steel structure cutting processing device, including a base 1, a bracket 2 arranged on the base 1, a processing panel 3 is arranged on the bracket, a clamp structure 4 is arranged on the processing panel, A cutting seat 5 is provided on the base 1, a cutting motor 6 is arranged on the cutting seat and a cutting tool 7 is fixed on the main shaft of the cutting motor, and the top surface opening in the processing panel is Concave cavity 8, in which a driving screw 9 is arranged, a fixture seat 10 is arranged on the driving screw, and a drive connected to the driving screw is fixed on the side of the processing panel. The motor 11 is provided with a card cavity 12 on the top surface of the clamp seat 10, and the clamp structure 4 includes a first clamping support block 41, a second clamping s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com