Maltose ion exchange deodorizing device

A maltose separation technology, applied in ion exchange treatment devices, maltose production, ion exchange, etc., can solve problems that plague fine processing and affect the quality of maltose production, achieve fast exchange speed, high work efficiency, and improve quality standards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

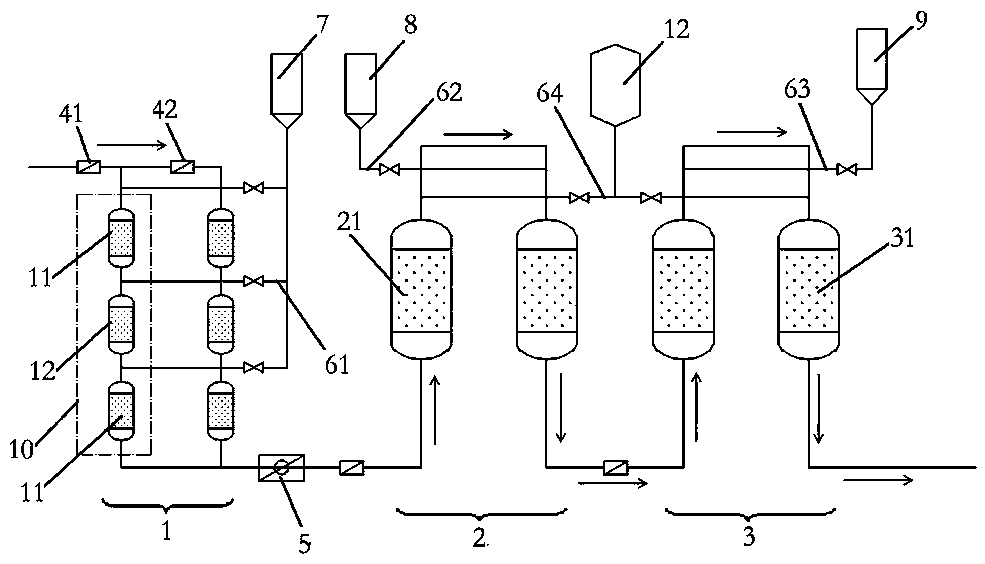

[0015] The structure and working principle of a maltose separation and deodorizing device provided by the present invention will be described in further detail below with reference to the accompanying drawings.

[0016] See figure 1 , Is a schematic structural diagram of a maltose separation and deodorizing device provided by the present invention. The structure of the maltose separation and deodorization device includes a separation column group 1, a mixed bed column group 2 and a deodorization column group 3, which are sequentially connected by connecting pipes. Among them, the separation column group 1 includes several D001-FD resins. The cation exchange column 11 and the anion exchange column 12 composed of D354-FD resin; the mixed bed column group 2 includes one or more mixed ion exchange columns 21 composed of DOWEX 88MB resin and DOWEX 22 resin; the deodorizing column group 3 includes one Or a plurality of ion exchange columns 31 composed of XAD-16N resin.

[0017] The work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com