Full-life-cycle intelligent monitoring gas density relay and implementation method thereof

A technology with full life cycle and gas density, applied in the power field, can solve problems such as flashover, performance degradation, and affecting the reliable operation of electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

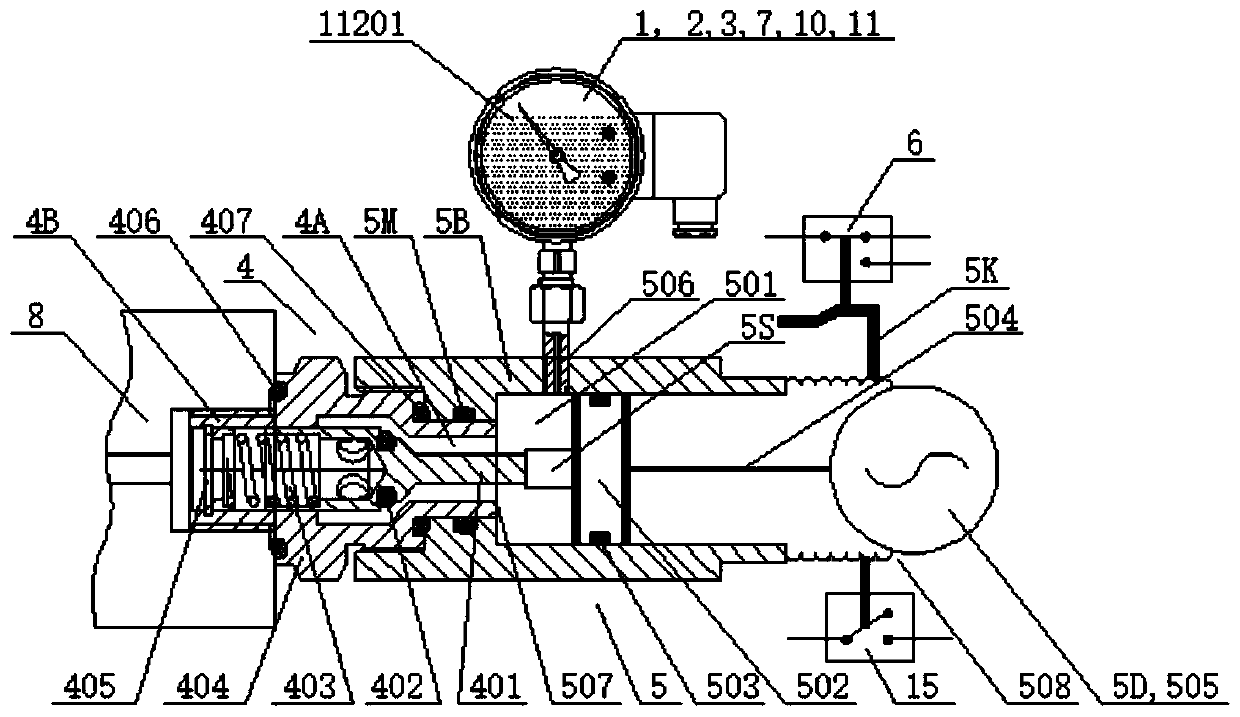

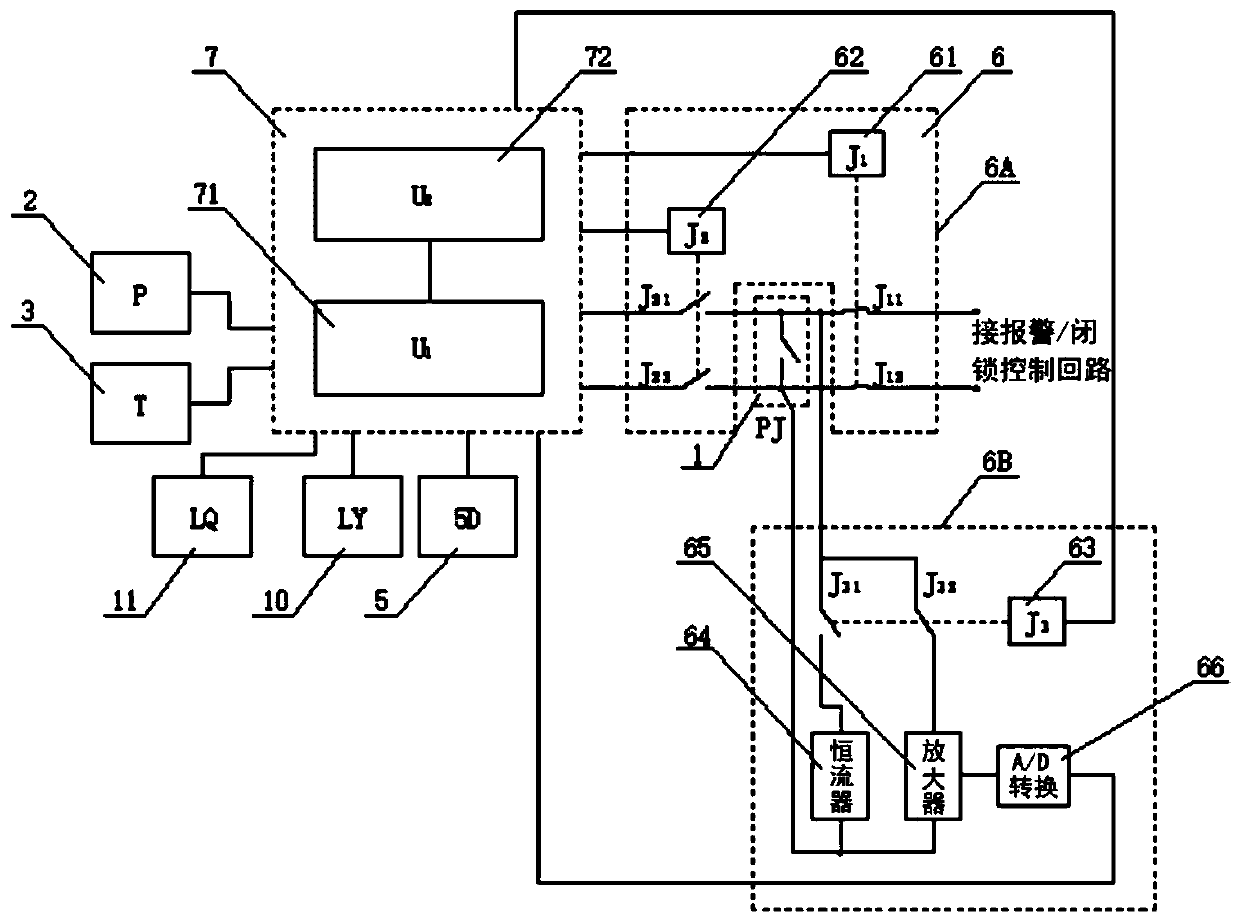

[0139] Figure 1 ~ Figure 2 It is a schematic structural diagram of a gas density relay used for high and medium voltage electrical equipment and intelligently monitored throughout its life cycle according to an embodiment of the present invention. The gas density relay for intelligent monitoring of the whole life cycle includes: the gas density relay body containing anti-vibration oil, the online calibration unit (including the pressure sensor 2, the temperature sensor 3, the valve 4, the pressure regulating mechanism 5, and the online calibration contact signal sampling Unit 6), intelligent control unit 7, oil leakage diagnosis detector 10, sealing performance detection unit 11 and contact resistance detection unit 6B. Among them, the gas density detection sensor (pressure sensor 2, temperature sensor 3), the intelligent control unit 7, the oil leakage diagnosis detector 10 and the sealing performance detection unit 11 are all set on the gas density relay body 1, and the conta...

Embodiment 2

[0172] Image 6 It is a schematic structural diagram of a gas density relay body used for high and medium voltage electrical equipment and intelligently monitored throughout its life cycle in the second embodiment of the present invention.

[0173] The difference between this embodiment and the first embodiment is:

[0174] The oil leakage diagnostic detector 10 of this embodiment is mainly composed of a video camera (or camera). The camera includes a camera body 1001 and a camera shield 1002. The camera is arranged outside the gas density relay body 1 (or inside the body). The principle is: the camera obtains the information of the gas density relay through image recognition technology, including oil leakage, water ingress, rust, foreign matter intrusion, blurred dial, rubber aging, rubber fracture, device damage, device falling, device jamming One or more of them, the intelligent control unit 7 or the background sends an oil leakage performance alarm signal or / and information. ...

Embodiment 3

[0179] Figure 7 It is a schematic structural diagram of a gas density relay body used for high and medium voltage electrical equipment and intelligently monitored throughout its life cycle in the third embodiment of the present invention.

[0180] The difference between this embodiment and the first embodiment is:

[0181] The sealing performance detection unit 11 is an SF6 diagnostic sensor 1101, and the SF6 diagnostic sensor 1101 may be arranged in the housing 102 of the gas density relay 1; or, the sealing performance detection unit 11 may also include a gas hood (or a leaking gas collector). ) 1102, the gas hood 1102 is arranged on the outside of the gas density relay body 1, and communicates with the housing 102 of the gas density relay body 1, forming a relatively sealed cavity (the SF6 diagnostic sensor and its bottom are required to be sealed , Can collect the leaked SF6 gas, that is, the upper part of the SF6 diagnostic sensor in the cavity may not be completely sealed). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com