Large-deformation composite extrusion preparation method for magnesium alloy profile for vertical hydraulic machine

A vertical hydraulic press and compound extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of extrusion head and tail, large difference in internal and external structure properties, single stress-strain mode, poor comprehensive mechanical properties, etc. Material utilization, huge economic benefits, and the effect of large plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

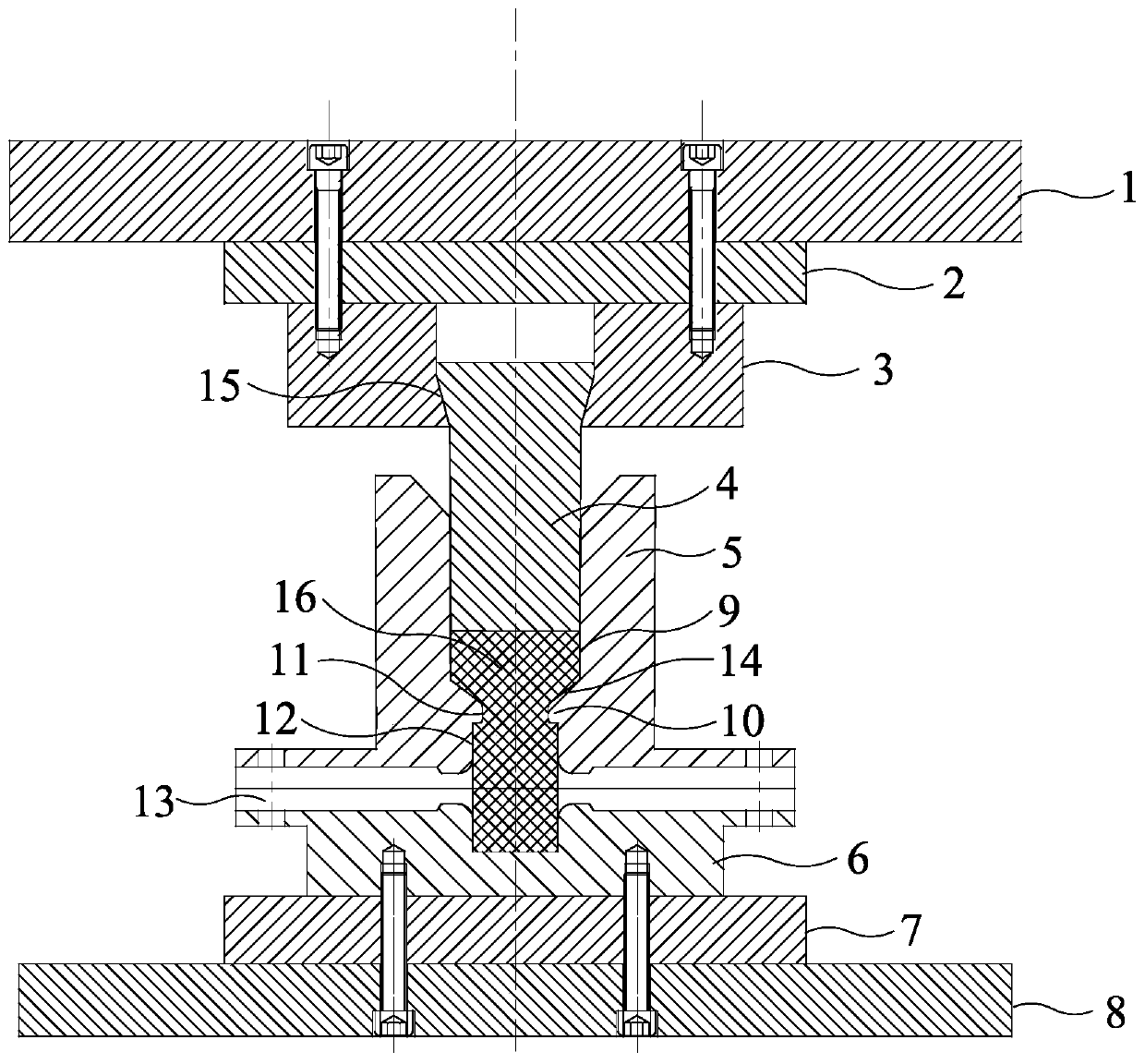

[0028] The invention relates to a large-deformation compound extrusion mold for magnesium alloy profiles for a vertical hydraulic press, comprising an upper mold assembly connected to the upper workbench of the vertical hydraulic press, a lower mold assembly connected to the lower workbench of the vertical hydraulic press, and a convex The die 4 and the split die, the punch 4 are coaxially located above the split die.

[0029] The split die includes an upper die 5 and a lower die 6, and the upper die assembly includes an upper template 1 connected to the upper worktable of the hydraulic press, an upper backing plate 2 connected with the upper template 1, and the upper backing plate 2 connected with the upper template 1. The upper mold base 3 connected by the upper backing plate 2, the middle part of the upper mold base 3 offers a mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com