An inspection device

An inspection device and vibration detection technology, which is applied in the direction of measuring devices, testing of machine/structural components, testing of mechanical components, etc., can solve problems such as inspection lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the present invention will be described below.

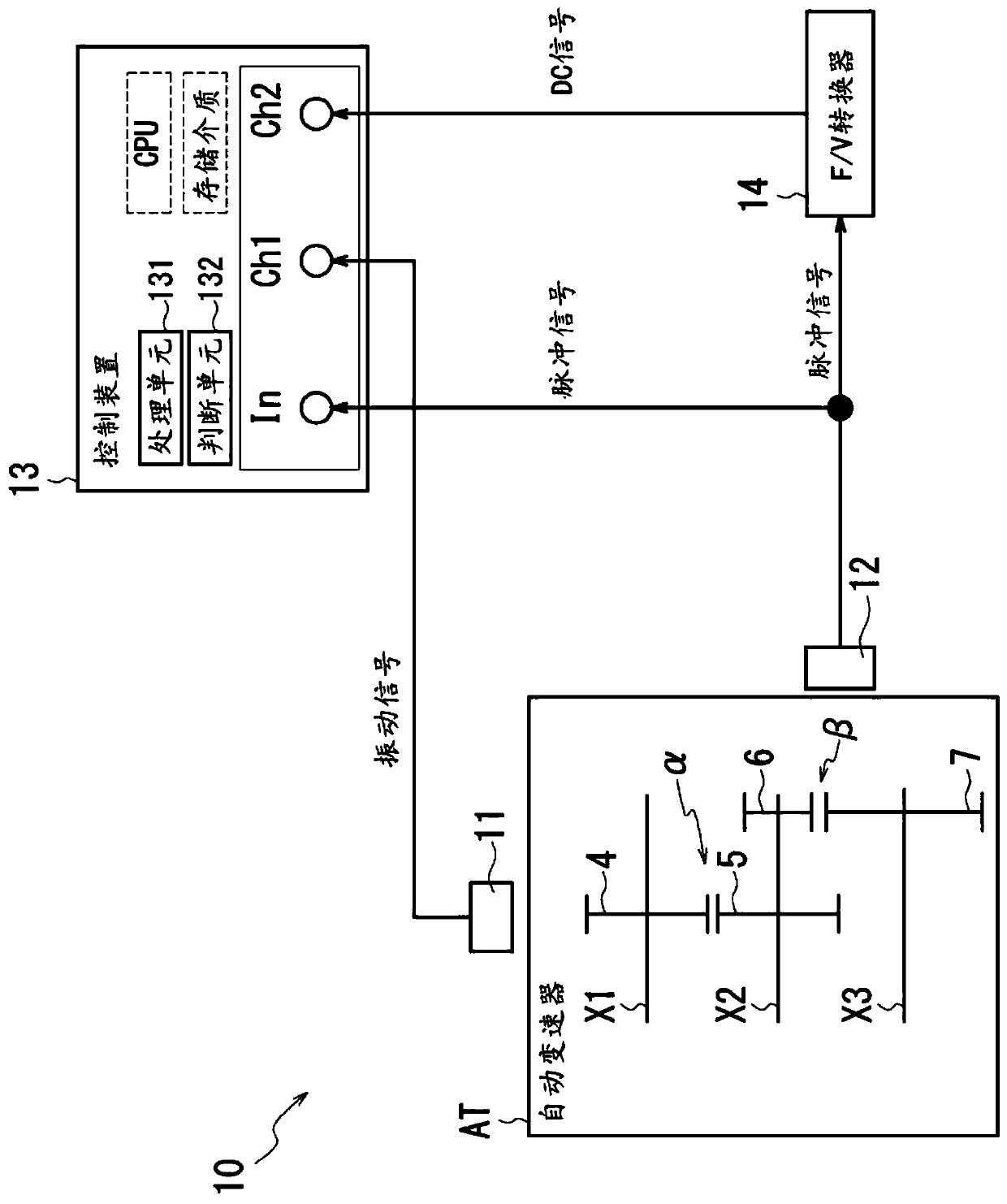

[0060] figure 1 It is a figure which shows the schematic structure of the inspection apparatus 10 of this embodiment.

[0061] The inspection device 10 includes a vibration sensor 11, a rotation sensor 12, a control device 13, and an F / V converter 14 (period / voltage converter).

[0062] The object to be inspected by the inspection device 10 is the automatic transmission AT for a vehicle. In the vehicular automatic transmission AT, a plurality of gear sets α, β are provided on a rotational driving force transmission path.

[0063] The inspection device 10 is provided for inspecting the presence or absence of defects in the gear members 4, 5, 6, 7 constituting the gear sets α, β.

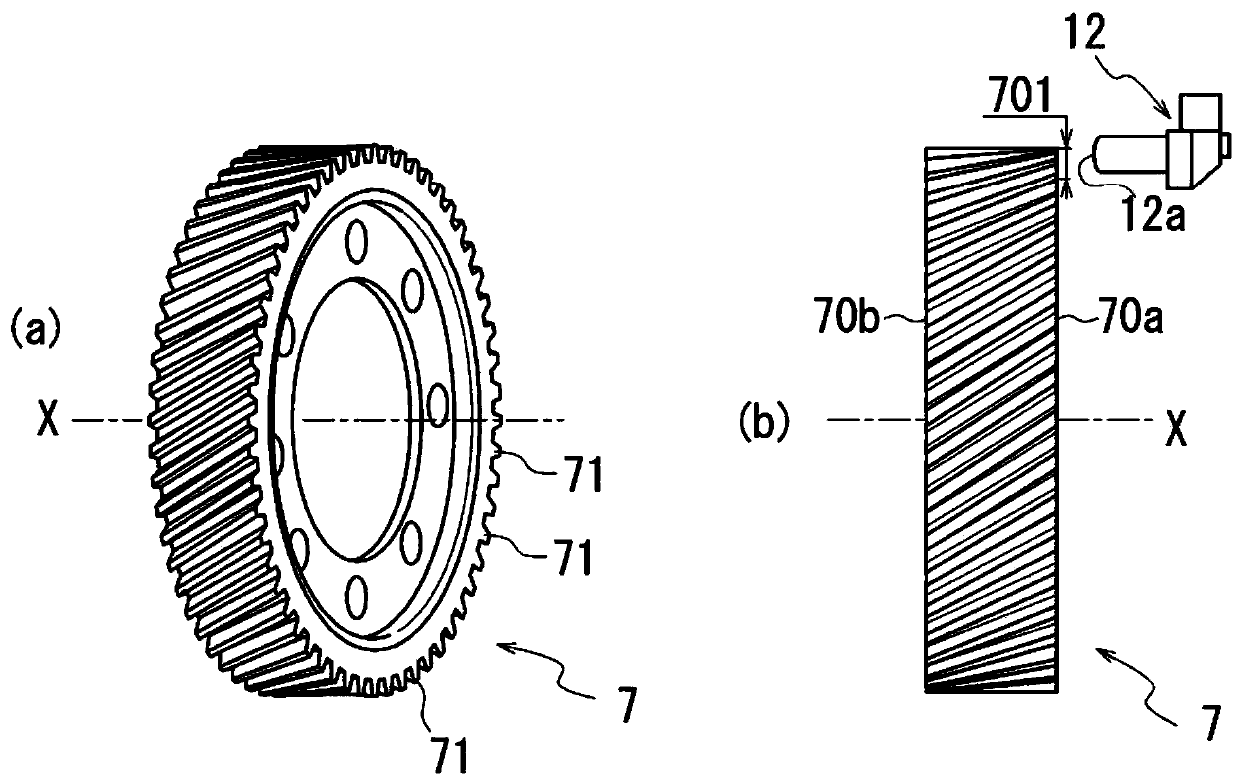

[0064] The process of manufacturing a gear part includes a step of grinding the surface of a tooth part that is a meshing surface with another gear part. The purpose of this process is: (a) to remove the surface of the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com