Immersion lithography device and immersion exposure method

A kind of equipment and lithography technology, applied in the direction of microlithography exposure equipment, printing equipment, photomechanical equipment, etc., can solve the problems of uneven coverage, difficulty in fluid removal, pollution, etc., and achieve the effect of low fluid vapor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention relates to immersion lithography, and more particularly to an immersion lithography system using a sealed wafer bottom.

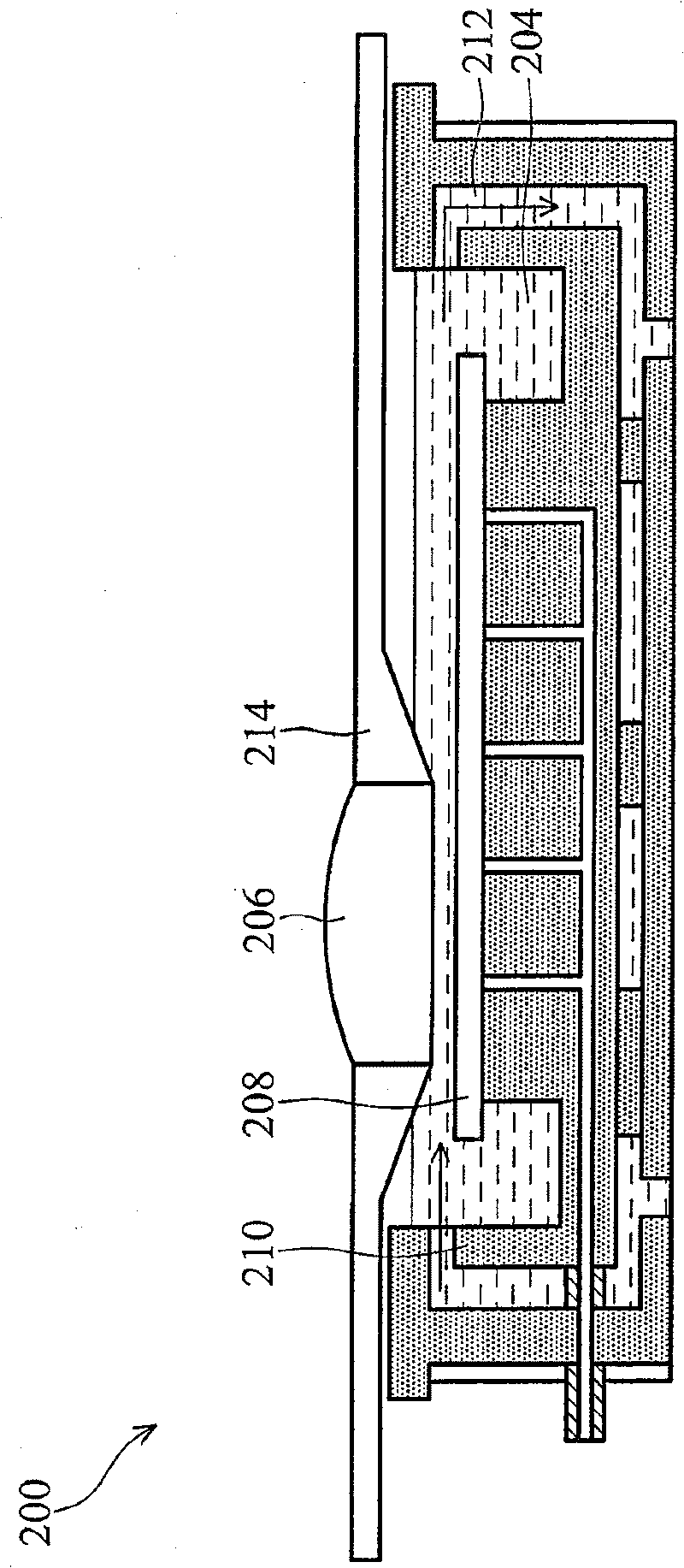

[0055] Please refer to image 3 , Figure 4 ,in image 3 and Figure 4 Shown are top and side views of an embodiment of an all-immersion lithography system 300; in this all-immersion lithography system 300, a seal ring is configured to contact the bottom edge of a wafer. Herein, such a total immersion lithography system may also be referred to as a "WISBOT" system. exist Figure 4 In the embodiment, the system 300 includes a wafer susceptor 302 and a wafer 304 may be held against the wafer susceptor 302 by a vacuum system 306 . A camera set 308 is placed on the wafer 304 . According to the present embodiment, an immersion fluid 309 is disposed in a region or groove 310 covering and surrounding the wafer 304 and between the wafer and the lens set 308 . The immersion fluid is retained within the tank 310 by a fluid retainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com