Catalyst for use in hydrolysis of carbonyl sulfide, and method for producing same

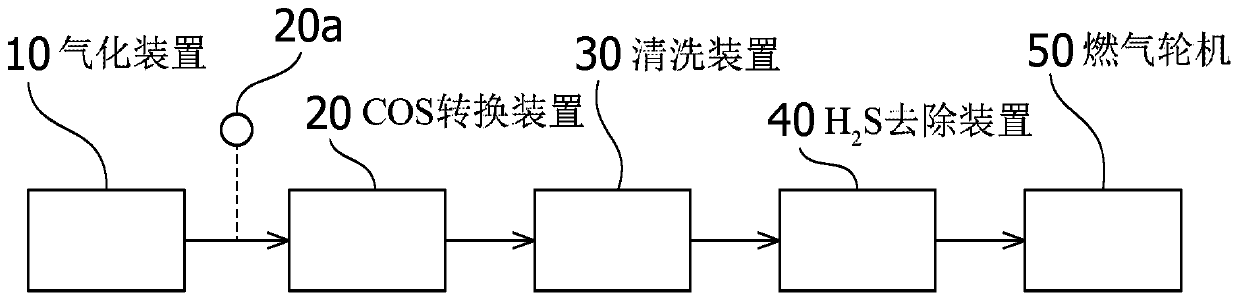

A manufacturing method and catalyst technology, which are applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unreachable COS conversion rate, inability to cope with raw gas, and inability to obtain high COS conversion rate. , to achieve the effect of improving COS conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

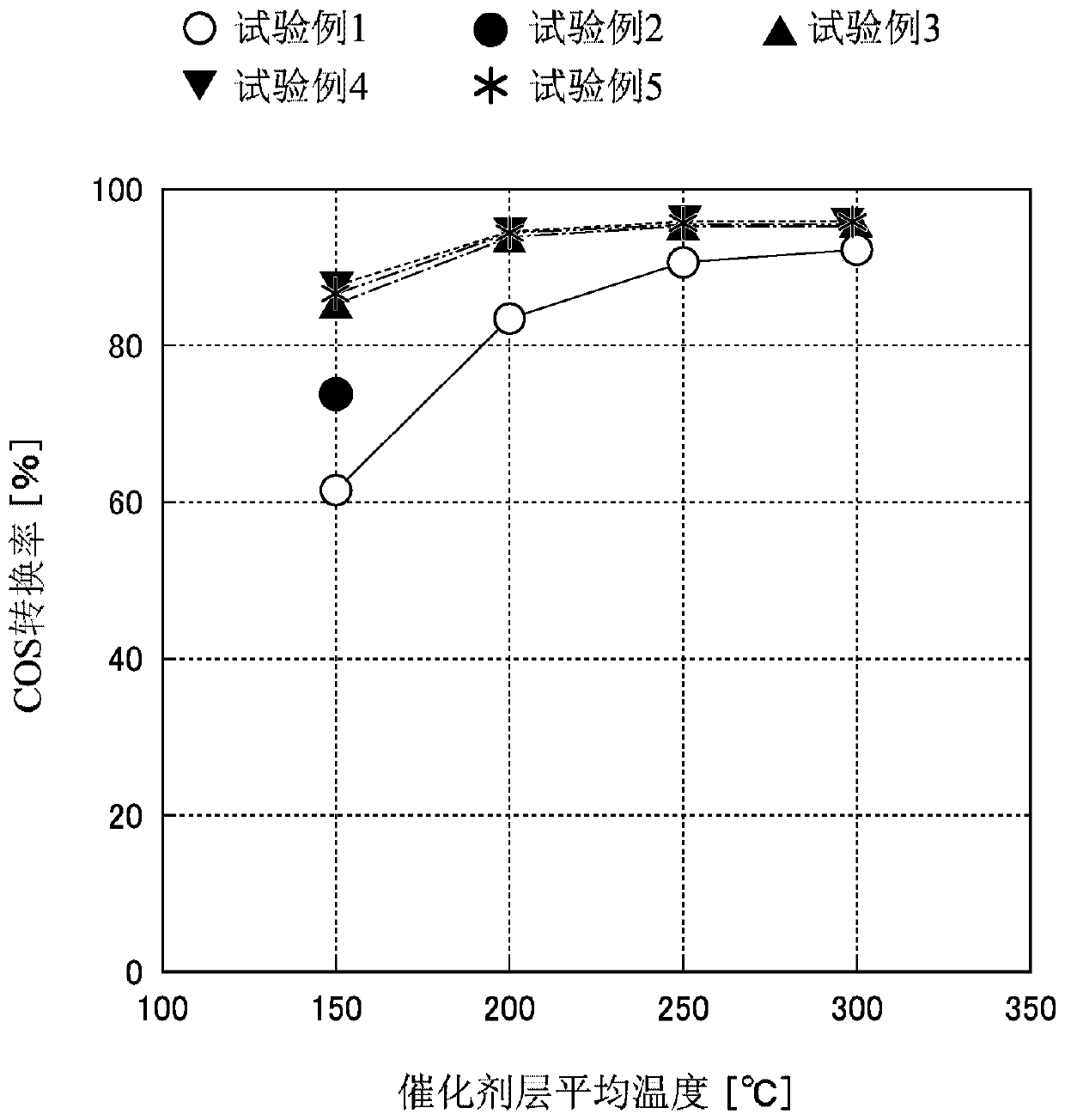

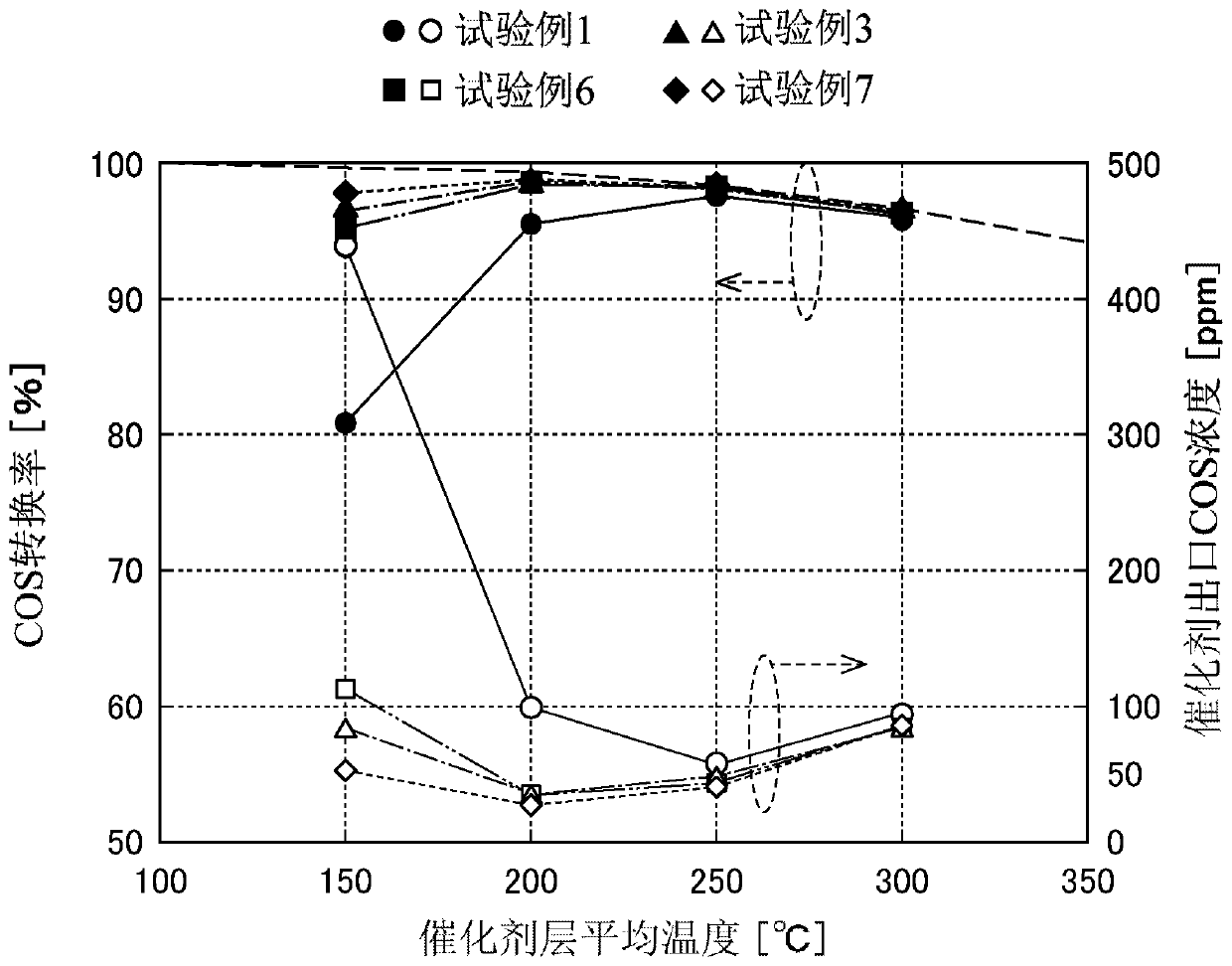

[0045] Hereinafter, the present invention will be described more specifically using examples. The catalyst for hydrolysis of carbonyl sulfide of the present invention and its production method are not limited to the following examples.

[0046] 1.1. Preparation of Catalyst I

[0047] As Test Example 1, 6 g of the following molded catalyst (2×2 cells, 150 mmL) was prepared, which was molded into a honeycomb shape, and a barium compound was supported on titanium dioxide (TiO 2 ) made. Anatase-type titanium dioxide was used as titanium dioxide as a carrier.

[0048] As Test Example 2, in the molded catalyst of Test Example 1, barium acetate ((CH 3 COO) 2 Ba) Aqueous solution. The shaped catalyst impregnated with water absorption was dried at 110° C., and then fired in air at 500° C. for 3 hours to support barium oxide on the shaped catalyst in an amount of 4% by weight relative to the shaped catalyst. In Test Example 2, 4% by weight of a barium compound was added as a cocat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com