Packaging method for inhibiting drifting and warping of chip

A packaging method and warping technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as adverse effects of charge carrier mobility, decreased bonding strength of rewiring layers, and impact on chip electrical performance , to achieve the effect of suppressing drift and warpage, suppressing drift and reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

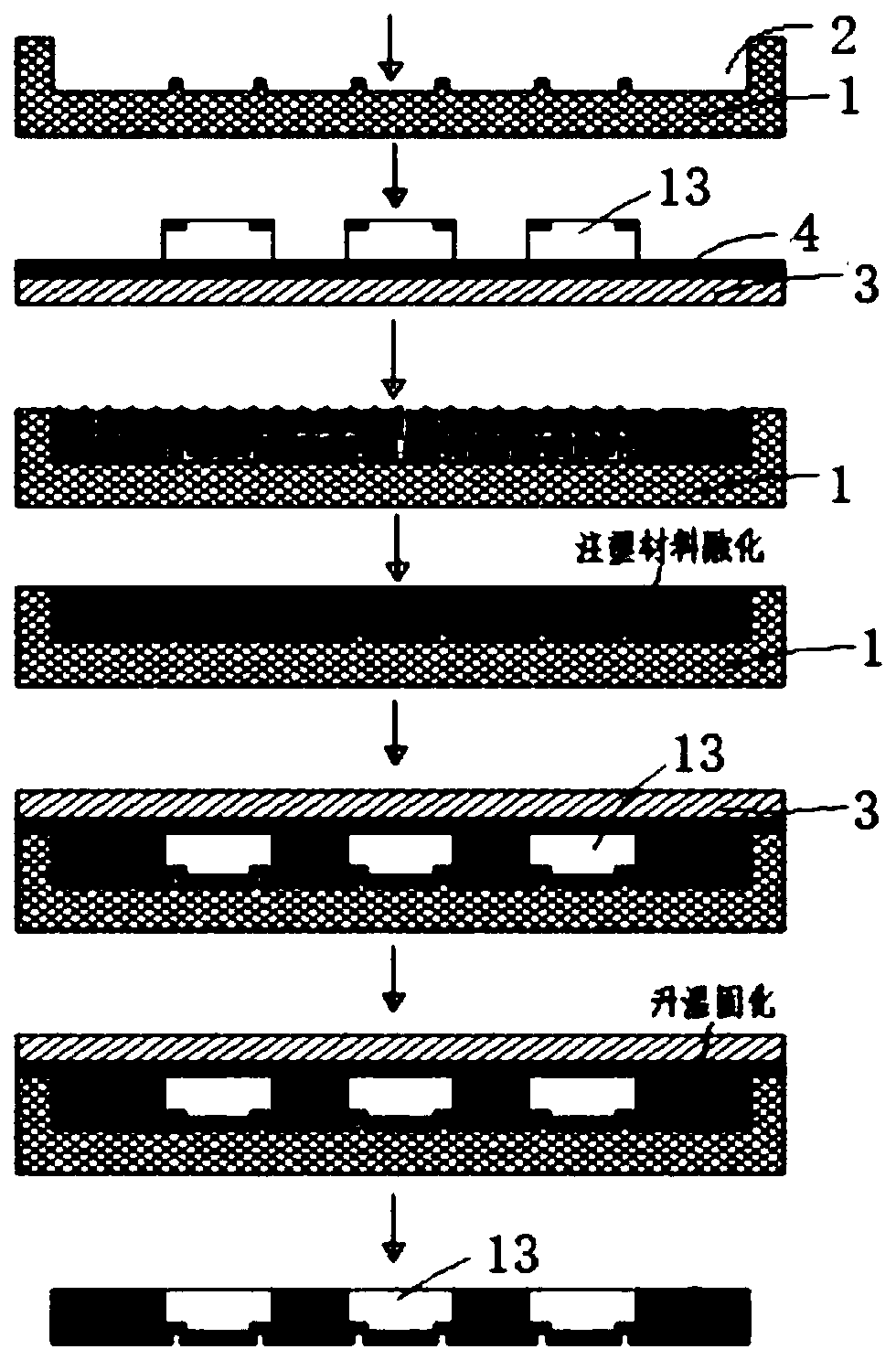

[0053] Such as figure 1 Shown is the first embodiment of the packaging method for suppressing chip drift and warping of the present invention, which includes the following steps:

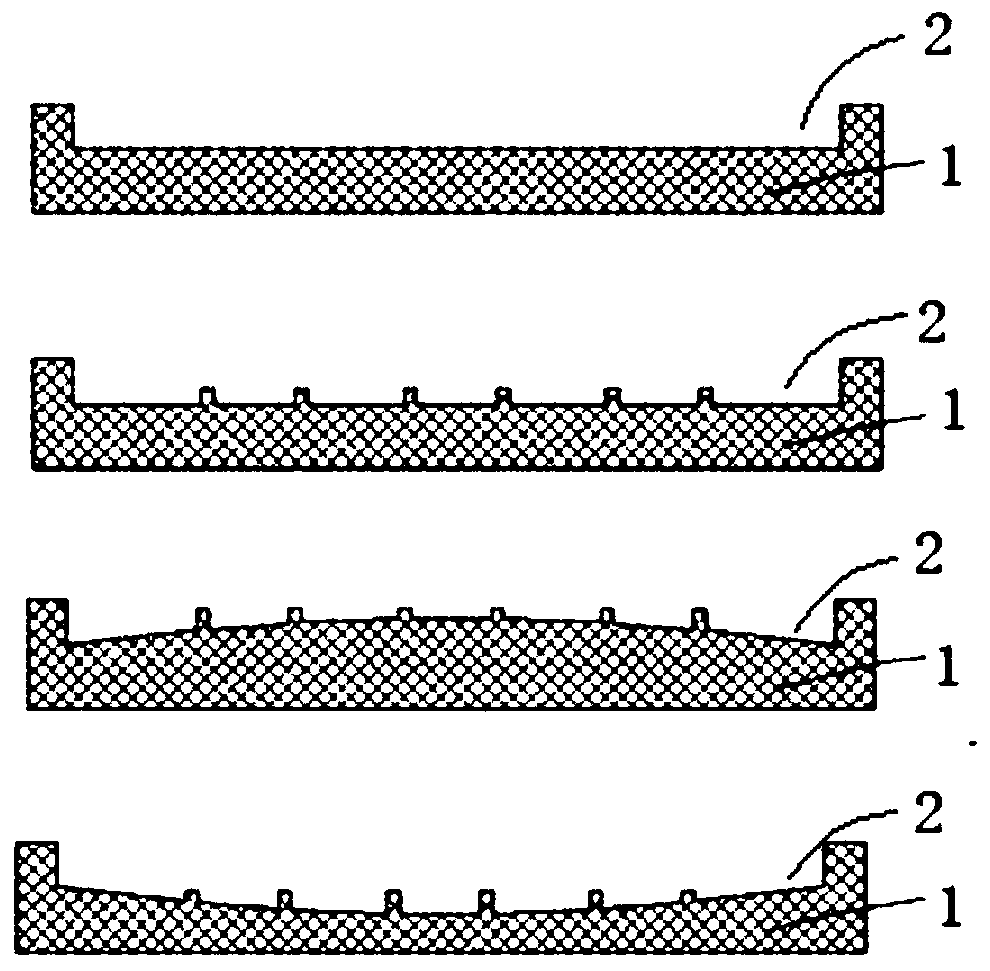

[0054] S10. Make the first groove 2 on the first rigid carrier 1, install the chips to be packaged on the second rigid carrier 3 covered with the temporary bonding layer 4 according to the required interval and position;

[0055] S20. Spread the injection molding material in the first groove 2 of the first rigid carrier 1, and raise the temperature above the glass transition temperature of the injection molding material to melt the injection molding material, forming a horizontal liquid level in the first groove 2 ;

[0056] S30. Move the second rigid carrier 3 on which the chip to be packaged is installed to the first rigid carrier 1 in such a way that the chip to be packaged faces downward so that the chip to be packaged is inserted into the molten injection molding material, and the second rigid...

Embodiment 2

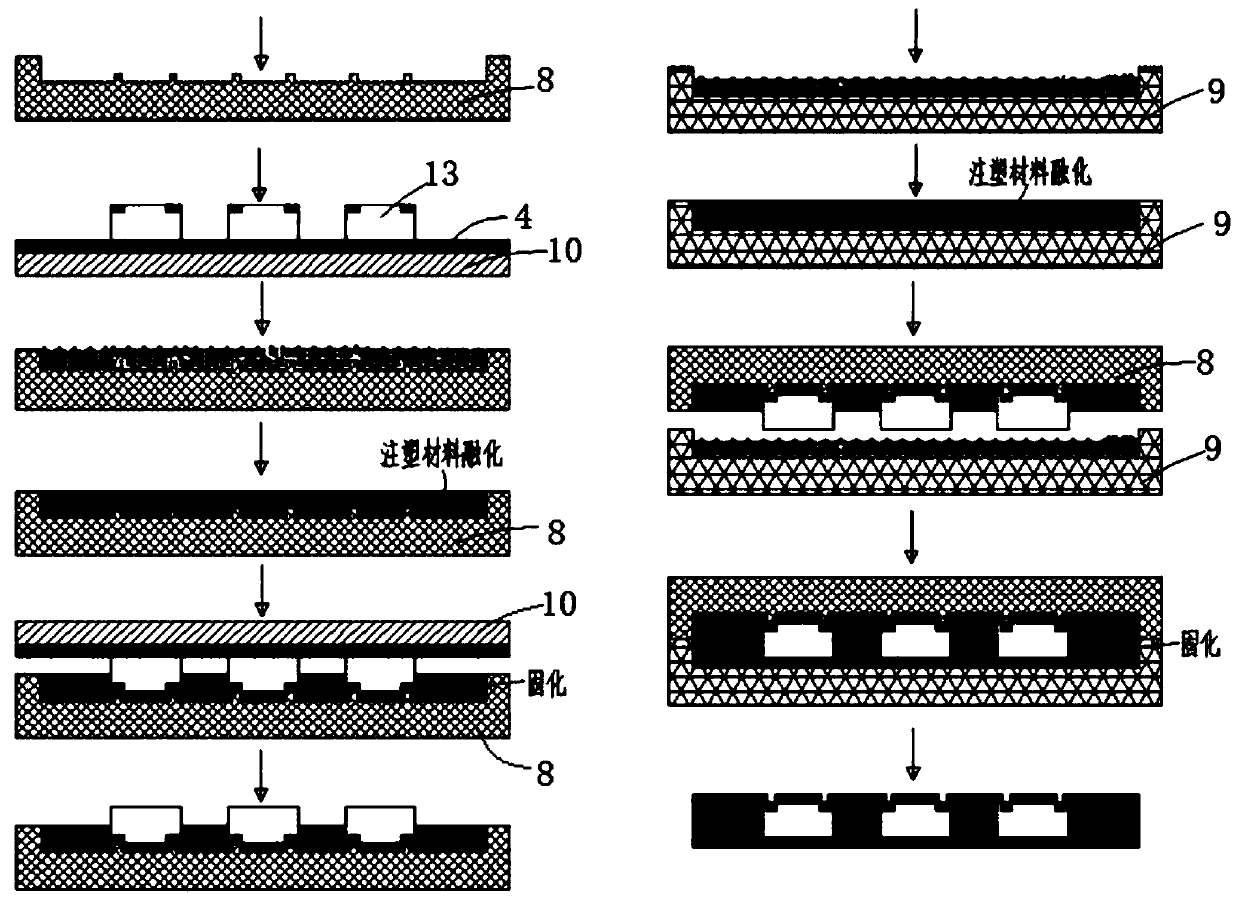

[0067] Such as image 3 Shown is the second embodiment of the package method for suppressing chip drift and warpage of the present invention. When a special curing sequence needs to be implemented, or the chip 13 to be packaged is thick or the viscosity of the injection molding material is too high, so that the chip 13 to be packaged cannot When the molten injection molding material is fully inserted, the method of multiple injection molding packaging can be used, including the following steps:

[0068] S10. Make a third groove with a package shape on the third rigid carrier 8, and make a fourth groove with a package shape on the fourth rigid carrier 9. The depth of the third groove is the same as that of the fourth groove. The sum of the depths of the grooves is equal to the height of the package;

[0069] S20. Install the chips 13 to be packaged on the fifth rigid carrier 10 covered with the temporary bonding layer 4 according to the required interval and position;

[0070...

Embodiment 3

[0080] Such as Figure 4 Shown is the third embodiment of the packaging method for suppressing chip drift and warpage of the present invention, when a special curing sequence is required, or the chip is thick or the viscosity of the injection molding material is too high, so that the chip cannot be completely inserted into the molten injection molding material When the method of multiple injection molding packaging can also be used; when the required final package height is consistent with the height of the chip, the packaging method to suppress chip drift and warpage includes the following steps:

[0081] S10. Make a sixth groove with a package shape on the sixth rigid carrier 11, the depth of the sixth groove is equal to the height of the chips to be packaged 13; the chips to be packaged 13 are installed in the required interval and position On the seventh rigid carrier 12 covered with the temporary bonding layer 4;

[0082] S20. Spread the fifth injection molding material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com