A high temperature shear test fixture for semiconductor chips

A shear test and semiconductor technology, applied in the direction of applying stable shear force to test the strength of materials, instruments, measuring devices, etc., can solve the problems that cannot meet the requirements of the chip shear test of surface mount components, and achieve easy replacement and heating The effect of fast speed and preventing uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

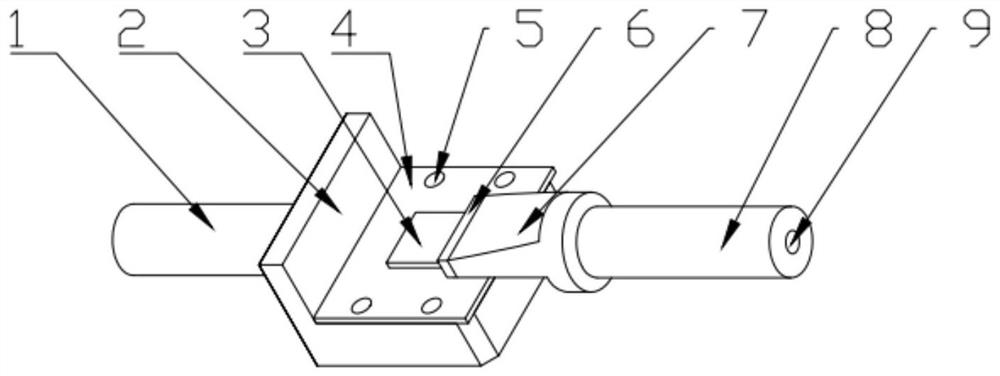

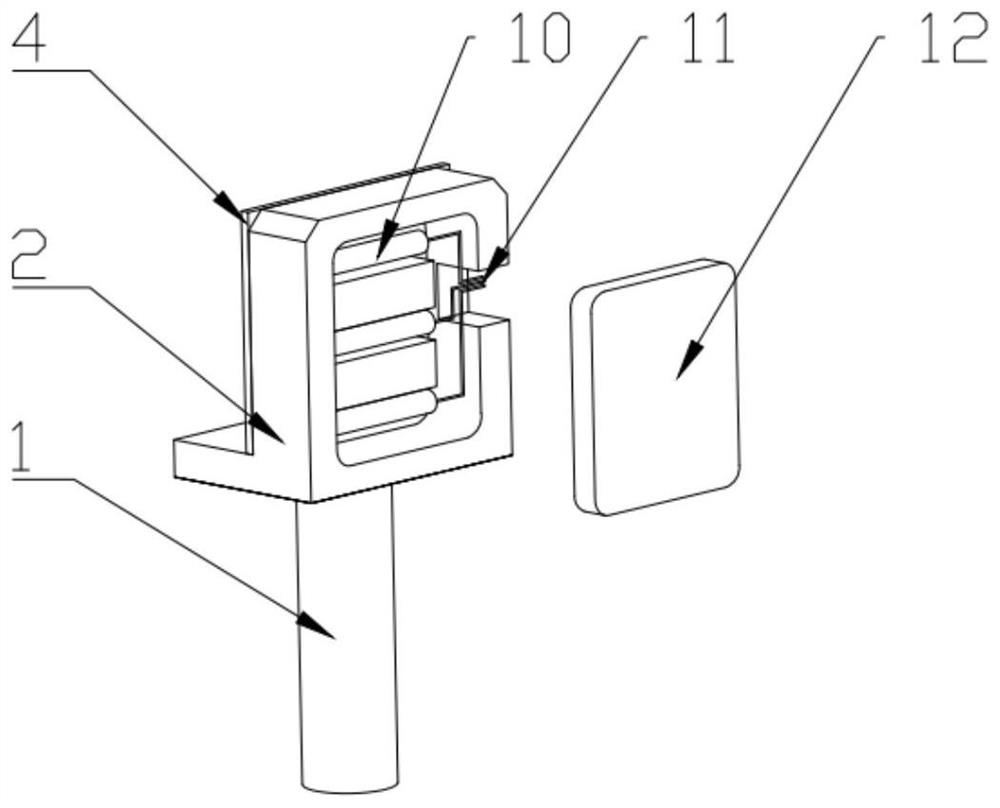

[0020] like figure 1 and figure 2 As shown, this embodiment provides a semiconductor chip high-temperature shear test fixture. The fixture is made of 4Cr13 high-temperature resistant material as a whole, and is composed of a connecting unit, a temperature loading unit and a force applying unit. The connection unit includes a first clamp connector 1 and a second clamp connector 8; the temperature loading unit includes a substrate fixing block 2, a ceramic heating rod 10, a wire 11 and a cover plate 12; the force applying unit includes a rubber strip 6 and a push head 7.

[0021] One end of the first clamp connector 1 is fixed to the load sensor of the output actuator by fastening screws, and the other end is connected to the substrate fixing block 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com