Spraying dust-reducing drill rod and method thereof

A technology for spray dust reduction and drill pipe, applied in drill pipe, dust prevention, drill pipe and other directions, can solve problems such as unfavorable workers' health and safety production, large on-site dust, etc., achieve good dust reduction effect, reduce dust harm, and facilitate The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

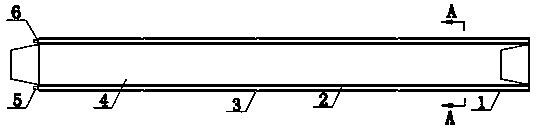

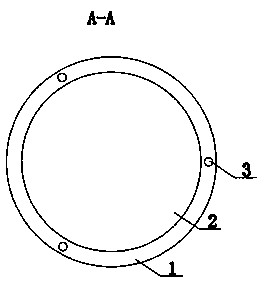

[0017] see Figure 1 ~ Figure 2 As shown, the technical solution adopted in this specific embodiment is: it comprises a drill pipe 1, a drill pipe outer channel 2, a nozzle 3, a drill pipe inner passage 4, a tapered mouth 5, an O-shaped sealing ring 6, and the drill pipe 1 includes a drill pipe outer passage 2 and a drill pipe inner passage 4, the said drill pipe outer passage 2 is provided with a nozzle 3, and the top of the drill pipe 1 is processed with a conical nozzle 5, and the said conical nozzle 5 An O-ring seal 6 is installed on it.

[0018] Further, the outer channel 2 of the drill rod is cylindrical with a diameter of 5mm.

[0019] Further, there are three outer passages symmetrically distributed in the drill pipe 1 .

[0020] Further, the diameter of the nozzle 3 is 2 mm, and the inclination angle of the nozzle 3 is 30 degrees.

[0021] Further, three groups of nozzles 3 are evenly distributed on the drill pipe 1, and each group of nozzles 3 has three nozzles sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com