Multi-drum washing machine

A washing machine, a combined technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of difficult to deal with the structure of multi-tub washing machines, limited application space, etc. Smooth effect of transmission of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

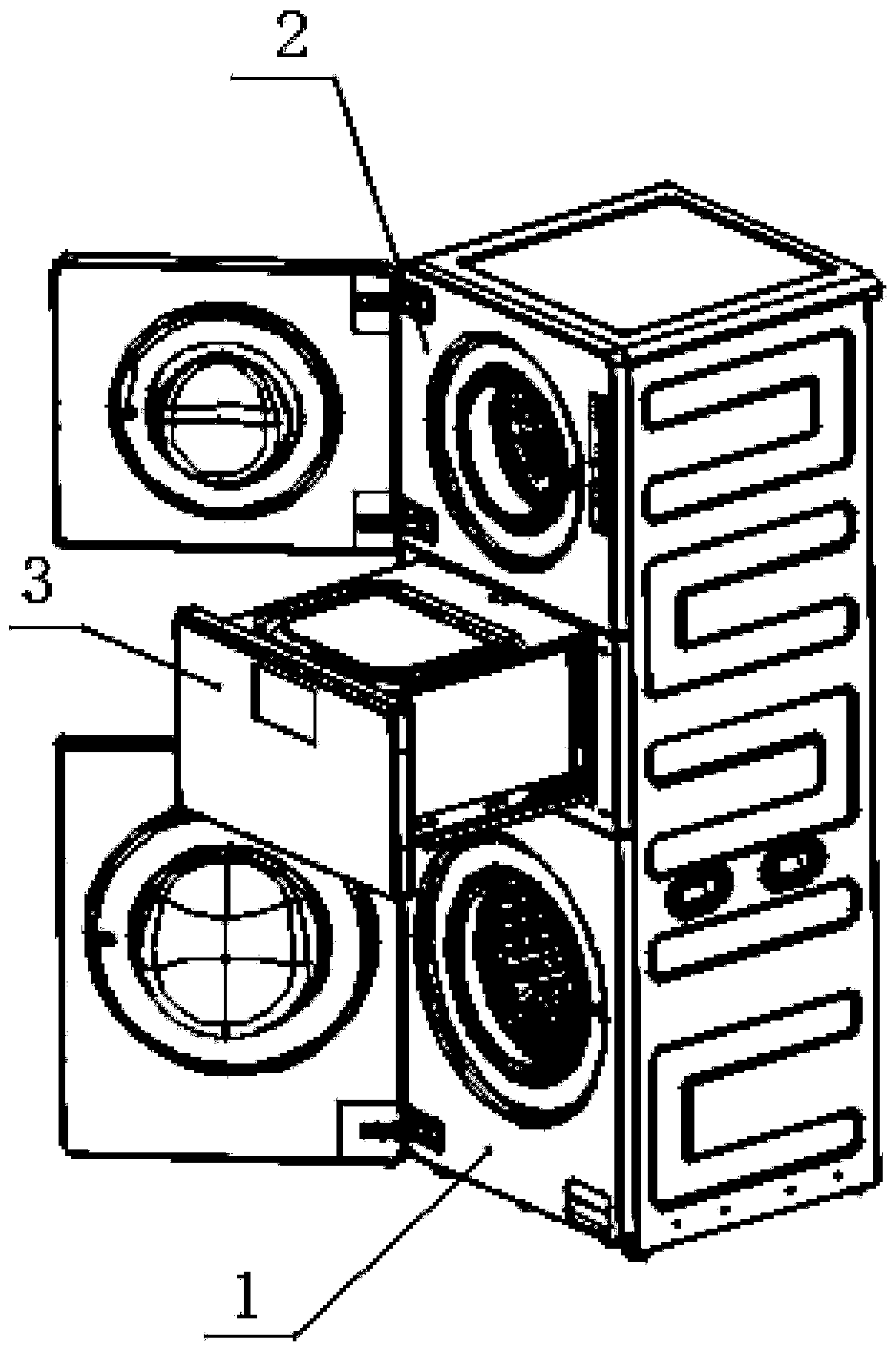

[0037] Such as figure 1 As shown, the present invention proposes a multi-tub washing machine, preferably a three-tub layout multi-tub washing machine layout form, which shows: the top layout of the multi-tub washing machine is a small drum washing machine, the middle layout is a drawer-type wavelet washing machine, and the bottom layout is For a large-drum washing machine, this embodiment provides invention protection for the type and location of the washing tubs in the three-tub washing machine.

[0038] The outer frame of the multi-tub washing machine is assembled with pressure riveting screws, the height meets the layout requirements of the three-tubs, the structural strength meets the vibration requirements of the three-tub operation, and the assembly form meets the process requirements, ensuring the structural strength of the whole machine when multi-tubs are in operation. , to ensure smooth transition of vibration during operation between multiple barrels, and centralize...

Embodiment 2

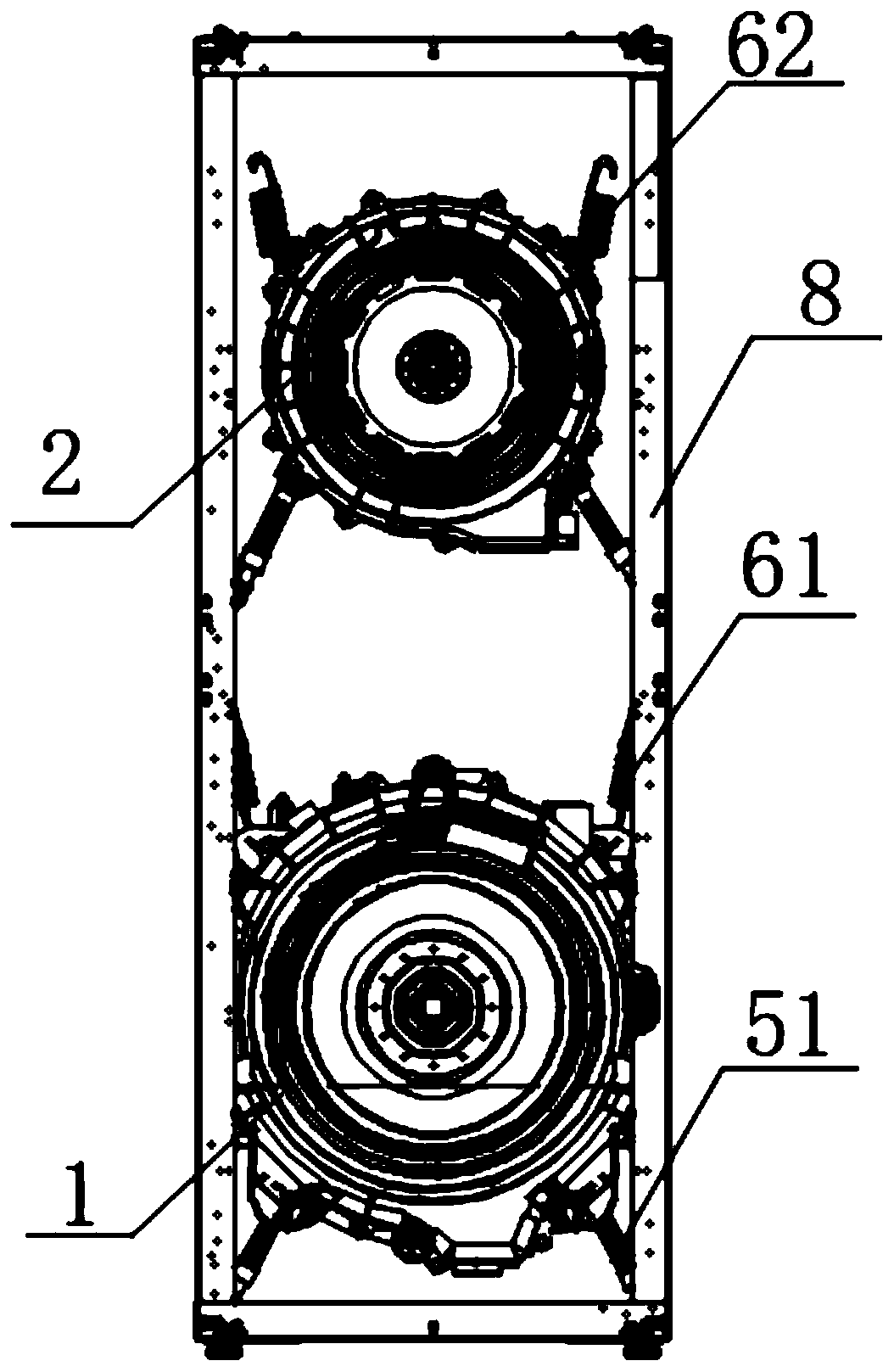

[0040] Such as figure 2 As shown in the structural layout of the multi-tub washing machine, the axial distance between the upper washing tub and the lower washing tub is too large. If a shock absorption system is arranged for a single washing tub, the shock absorption system will disperse the vibration of the upper washing tub and the lower washing tub. , because the position of the upper washing bucket is relatively higher than the center of gravity of the whole machine, when the vibration of the upper washing bucket is dealt with separately, it will generate forward, backward, left, right, upward and downward external forces when the upper bucket is running, which makes the During the operation of the multi-tub washing machine, there is a risk of tipping forward, backward, left, and right, which poses a great safety hazard.

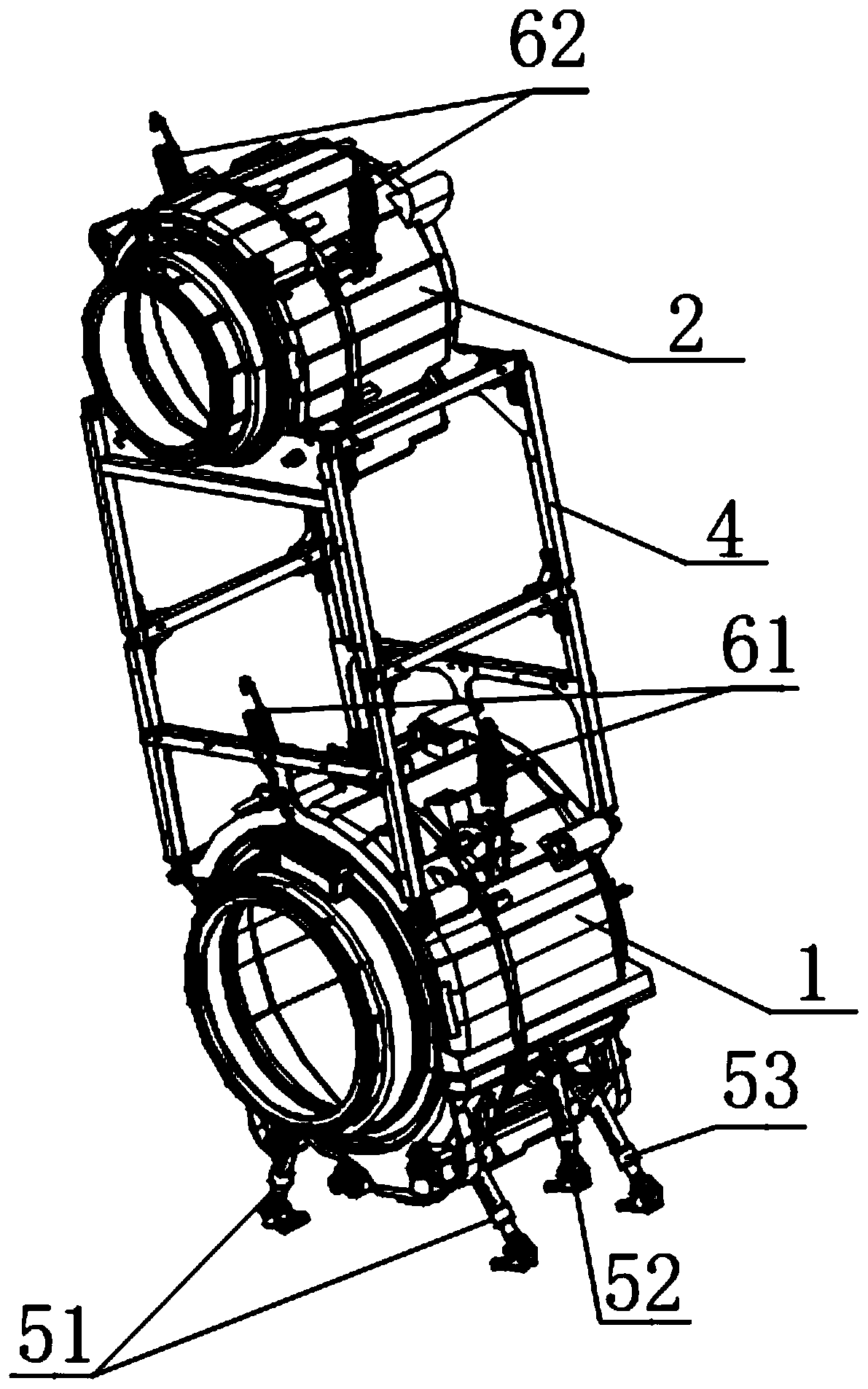

[0041] Such as image 3 As shown, in view of the characteristics of the multi-tub washing machine, the upper washing tub and the lower washing tub are ...

Embodiment 3

[0051] Such as image 3 , as shown in 4, the damping structure above the upper and lower washing buckets is all designed with double hanging springs, and the suspension points are all higher than the axis (center of circle) of the cylinder of the washing bucket. One end of the hanging spring is connected to the outer bucket side of the washing bucket, and the other One end is connected to the whole machine frame of the multi-tub washing machine; the left and right symmetrical layout of the four hanging springs supports the upper and lower washing buckets in the whole machine frame; the left and right symmetrical layout makes the integrated structure of the upper and lower washing buckets run The vibration transmission in the middle is more stable, and the shock absorber at the bottom can counteract the vibration more reasonably, making the whole machine run more stably.

[0052] Through simulation experiments, according to the structural characteristics of multi-tub washing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com