Preparation method of antibacterial titanium product

A product, the technology of titanium gold, applied in the field of nitrogen oxide layer, can solve the problems of being easily oxidized, limiting the application of titanium metal, and difficult to extract, so as to improve the antibacterial effect, broaden the range of light absorption, corrosion resistance and Excellent grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

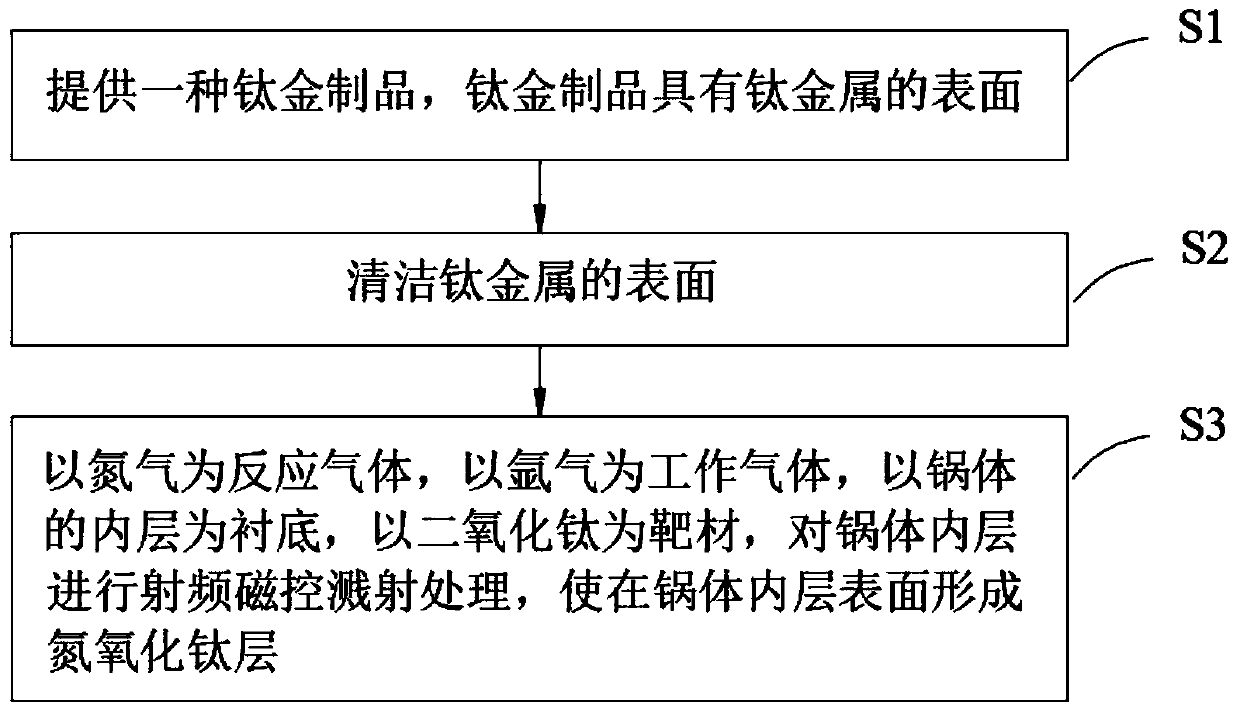

[0019] According to one aspect of the present invention, there is provided a method for preparing a bacteriostatic titanium gold product, including the following steps:

[0020] S1: Provide a titanium gold product, which has a surface of titanium metal;

[0021] S2: Clean the surface of titanium metal;

[0022] S3: Using nitrogen as the reaction gas, argon as the working gas, using the surface of titanium as the substrate, and using titanium dioxide as the target material, perform RF magnetron sputtering treatment on the surface of the titanium metal to form formation on the surface of the titanium metal Titanium oxynitride film.

[0023] Titanium metal includes industrial pure titanium and titanium alloys, such as TA1, TA2, TA3, Ti-6Al-4V (TC4), Ti-5Al-2.5Sn (TA7) and so on.

[0024] In some embodiments, in step S1, acetone is used to clean the surfaces of stainless steel circular plates, pure aluminum circular plates, and titanium metal circular plates to wash away impurities and oil...

Embodiment 1

[0030] A thin film of titanium oxynitride is formed on the inner surface of the titanium pan. The titanium pot is heated to 350℃, N 2 The flow rate is 2.5 sccm, the flow rate of Ar is 90 sccm, the power of RF magnetron sputtering is 300W, and the treatment time of RF magnetron sputtering is 5h. Under this process condition, the thickness of the oxynitride formed on the surface of the titanium metal reaches about 0.8 μm.

Embodiment 2

[0032] A thin film of titanium oxynitride is formed on the inner surface of the titanium pan. The titanium pot is heated to 375℃, N 2 The flow rate is 2.75 sccm, the flow rate of Ar is 95 sccm, the power of RF magnetron sputtering is 300W, and the treatment time of RF magnetron sputtering is 6h. Under this process condition, the thickness of the oxynitride formed on the surface of the titanium metal reaches about 1.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com