Wear-resistant self-lubricating material for mooring, preparation method thereof and fairlead

A technology of self-lubricating materials and fairleads, applied in the field of wear-resistant materials, can solve the problems of difficult welding process, high cost of stainless steel, inconvenient installation, etc., and achieve the effects of reducing operating costs, prolonging service life, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

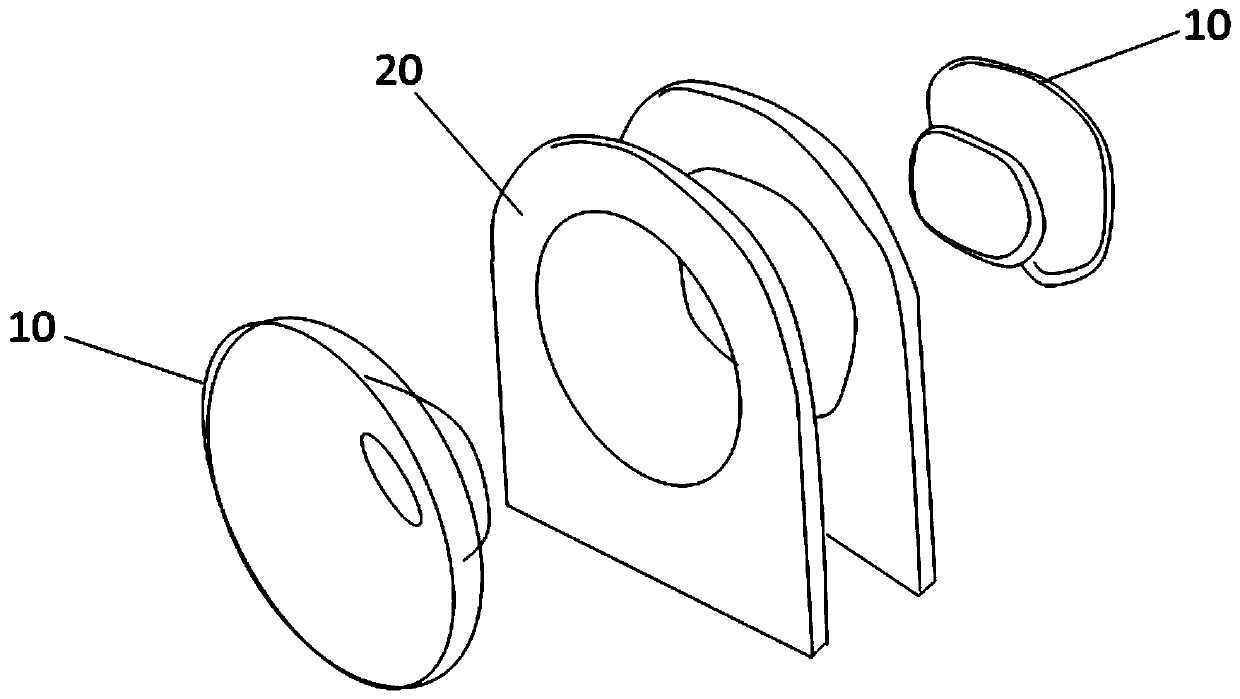

Image

Examples

Embodiment 1

[0028] This example provides a wear-resistant self-lubricating material for mooring, including the following preparation raw materials in parts by weight:

[0029] Base resin: 10-90 parts,

[0030] Solid lubricant: 5 to 40 parts,

[0031] Inorganic additives: 1-10 parts.

[0032] Among them, 5-40 parts by weight of reinforcing fibers are also included.

[0033] The reinforcing fibers are selected from at least one of glass fibers, metal fibers, graphite fibers and boron fibers.

[0034] The substrate resin is a mixed resin of polyether ether ketone and polytetrafluoroethylene with a mass ratio of 1:3-5.

[0035] The solid lubricant is a mixture of molybdenum disulfide, graphite fluoride and silicon nitride in a mass ratio of 1:2 to 5:1.

[0036] The inorganic additive is a mixture of calcium carbonate, silicon dioxide and copper-aluminum powder in a mass ratio of 3:3:1.

Embodiment 2

[0038] This example provides a method for preparing a wear-resistant self-lubricating material for mooring. In this method, the base resin, solid lubricant and inorganic additives are mixed and melted, and then formed. The melting temperature is 350°C.

Embodiment 3

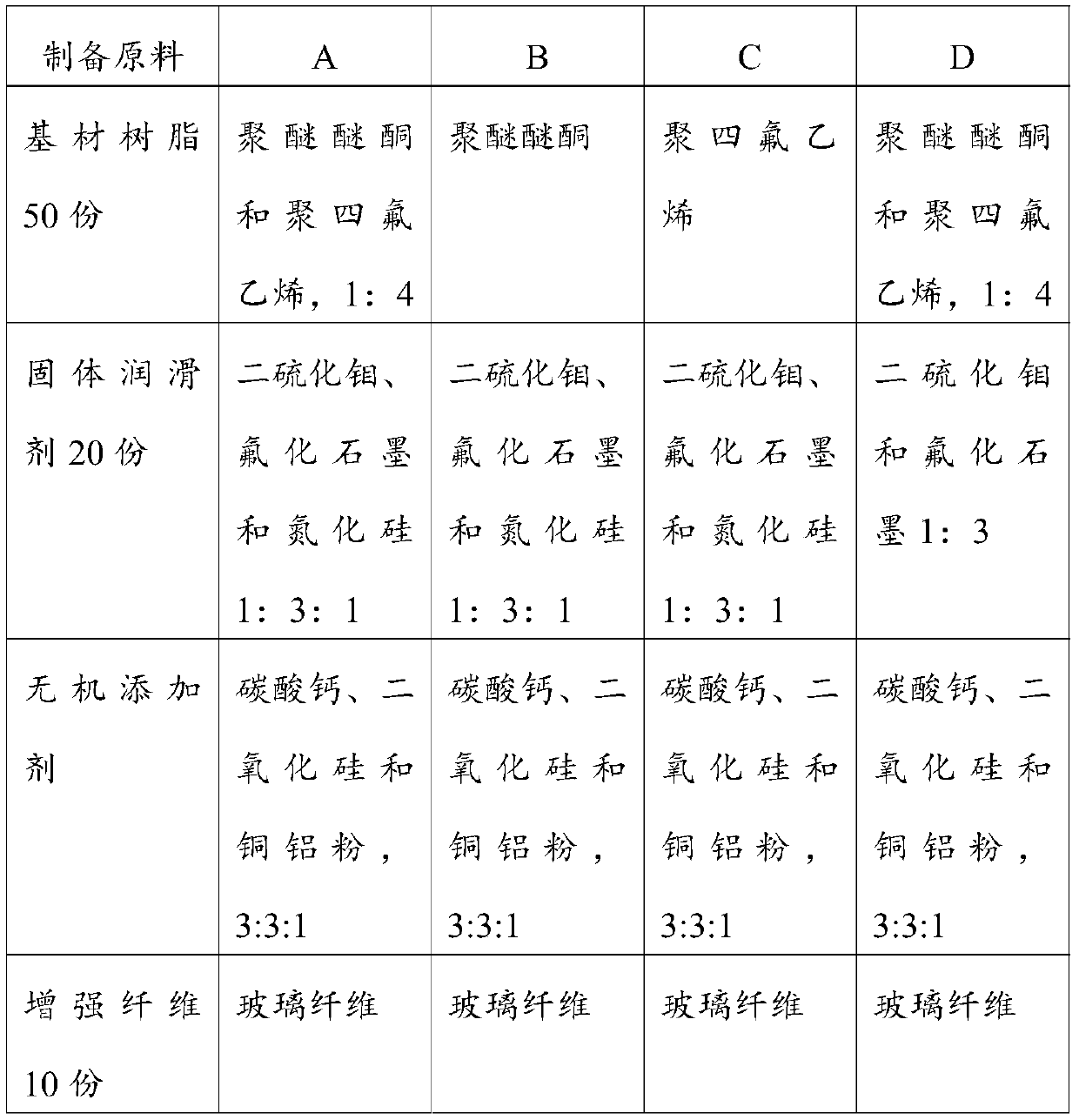

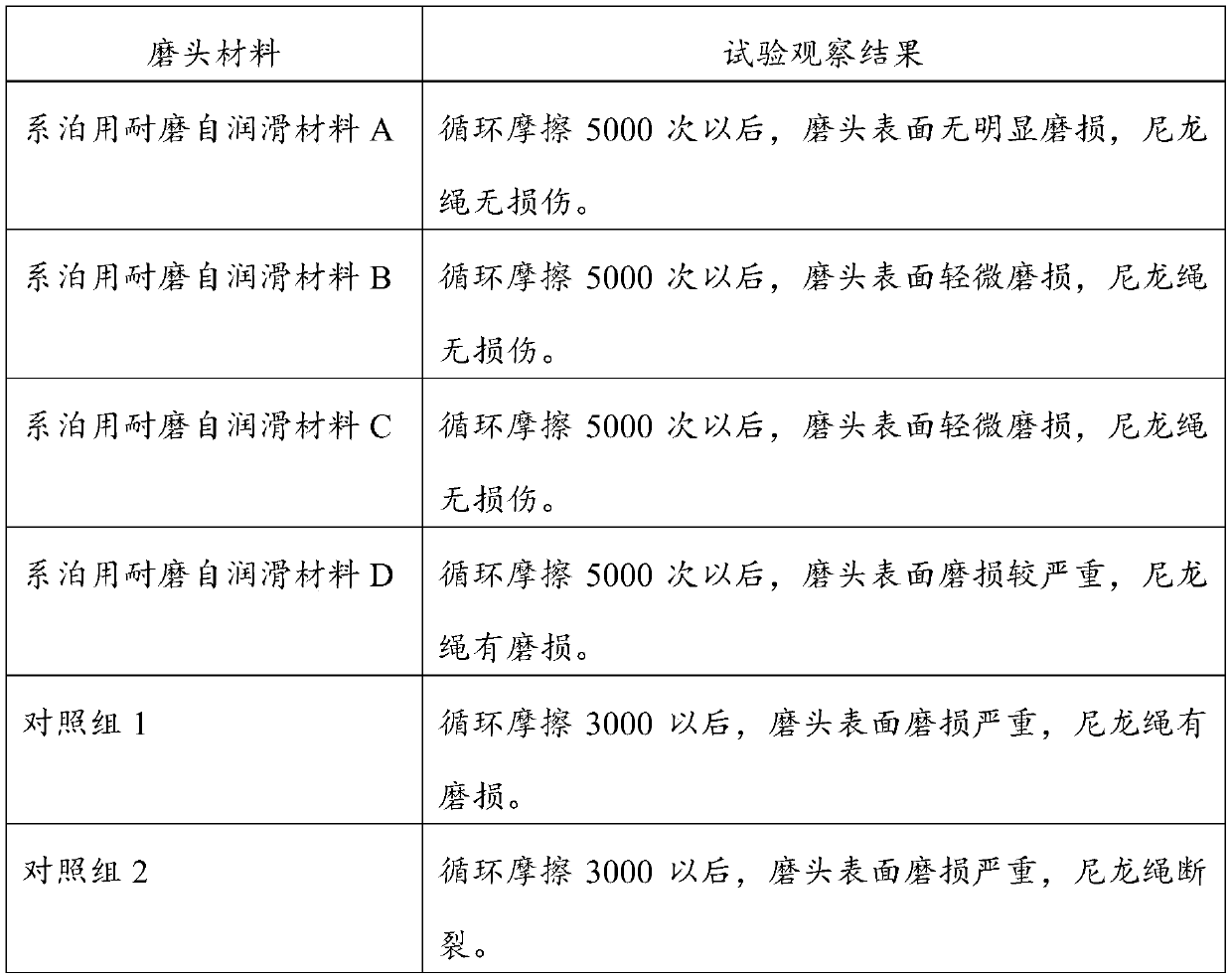

[0040] In this example, using the formulation of Example 1 and the preparation method of Example 2, four kinds of wear-resistant and self-lubricating materials for mooring, A to D, were prepared. The specific configuration is shown in Table 1.

[0041] Table 1 Material formula details

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com