Preparation method of high-purity mangiferin crystals

A mangiferin and crystallization technology, which is applied in the field of plant extraction, can solve the problems of hard cell wall of dry products, affecting the extraction rate and high production cost, and achieves the effects of easy industrial production, good repeatability and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

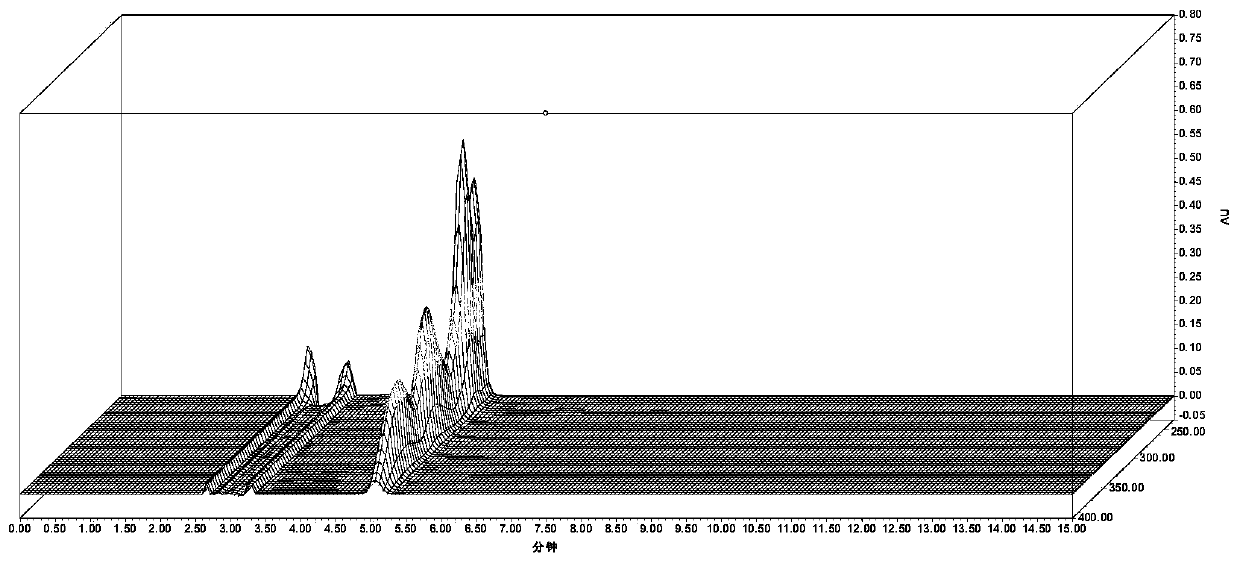

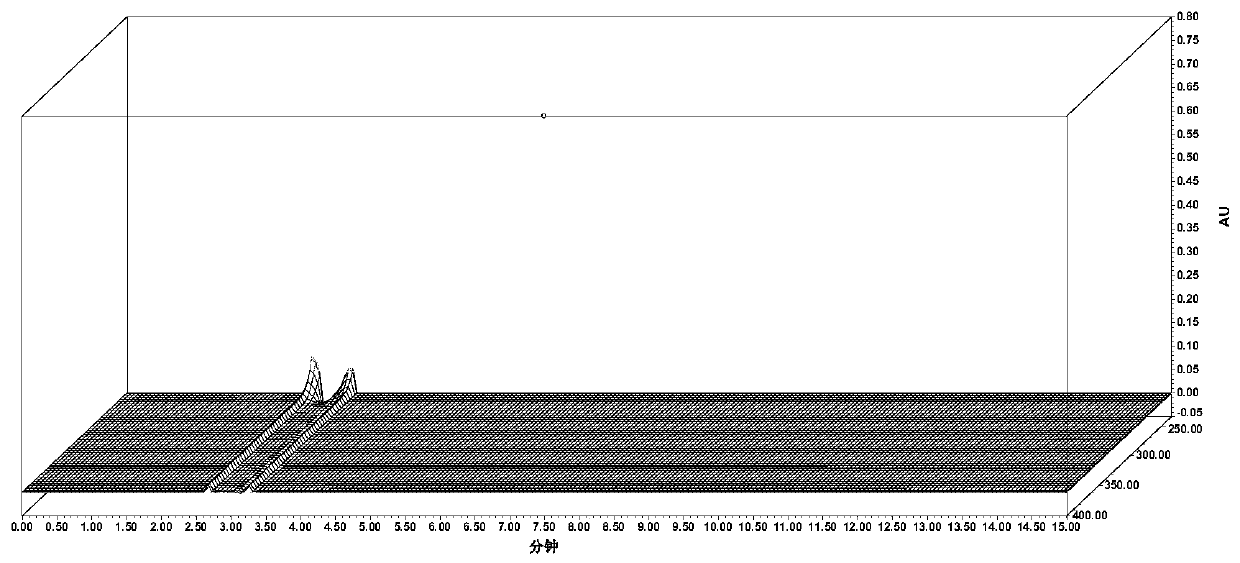

Image

Examples

Embodiment 1

[0041] A preparation method for high-purity mangiferin crystals, comprising the following steps:

[0042] S1. Mangiferin extract: Take fresh mango skin and mango leaves, crush them, and use 2 times the amount of alcohol solution to ultrasonically extract twice, each time for 20 minutes; combine the extracts, filter, and concentrate under reduced pressure to obtain mangiferin extract;

[0043] S2. Crude mangiferin crystallization: extract the mangiferin extract 4 times with 1 times the amount of ethyl acetate, remove the ethyl acetate layer, then extract 4 times with 1 times the amount of mangiferin extract with petroleum ether, and remove the petroleum ether layer , to obtain the mangiferin extract after impurity removal and decolorization, place it in a constant temperature water bath at 40°C to evaporate the solvent, place it in a hot air drying oven at a constant temperature of 40°C for 24 hours, and obtain the crude mangiferin crystals;

[0044] S3. Mangiferin redissolutio...

Embodiment 2

[0047] A preparation method for high-purity mangiferin crystals, comprising the following steps:

[0048] S1. Mangiferin extract: take fresh mango skin and mango leaves, crush them, and use 4 times the amount of alcohol solution to ultrasonically extract 4 times, each time for 40 minutes; combine the extracts, filter, and concentrate under reduced pressure to obtain mangiferin extract;

[0049] S2. Crude mangiferin crystallization: extract the mangiferin extract twice with 3 times the amount of ethyl acetate, remove the ethyl acetate layer, then extract twice with 3 times the amount of mangiferin extract petroleum ether, and remove the petroleum ether layer , to obtain the mangiferin extract after impurity removal and decolorization, place it in a 70°C constant temperature water bath to evaporate the solvent, place it in a hot air drying oven at a constant temperature of 70°C for 36 hours, and obtain the crude mangiferin crystals;

[0050] S3. Mangiferin redissolution: take th...

Embodiment 3

[0053] A preparation method for high-purity mangiferin crystals, comprising the following steps:

[0054] S1. Mangiferin extract: Take fresh mango skin and mango leaves, crush them, and use 2 times the amount of alcohol solution to ultrasonically extract 3 times, each time for 20 minutes; combine the extracts, filter, and concentrate under reduced pressure to obtain mangiferin extract;

[0055] S2. Crude mangiferin crystallization: extract the mangiferin extract three times with 1 times the amount of ethyl acetate, remove the ethyl acetate layer, then extract 3 times with 1 times the amount of mangiferin extract with petroleum ether, and remove the petroleum ether layer , to obtain the mangiferin extract after impurity removal and decolorization, place it in a constant temperature water bath at 40°C to evaporate the solvent, place it in a hot air drying oven at a constant temperature of 40°C for 24 hours, and obtain the crude mangiferin crystals;

[0056] S3. Mangiferin rediss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com