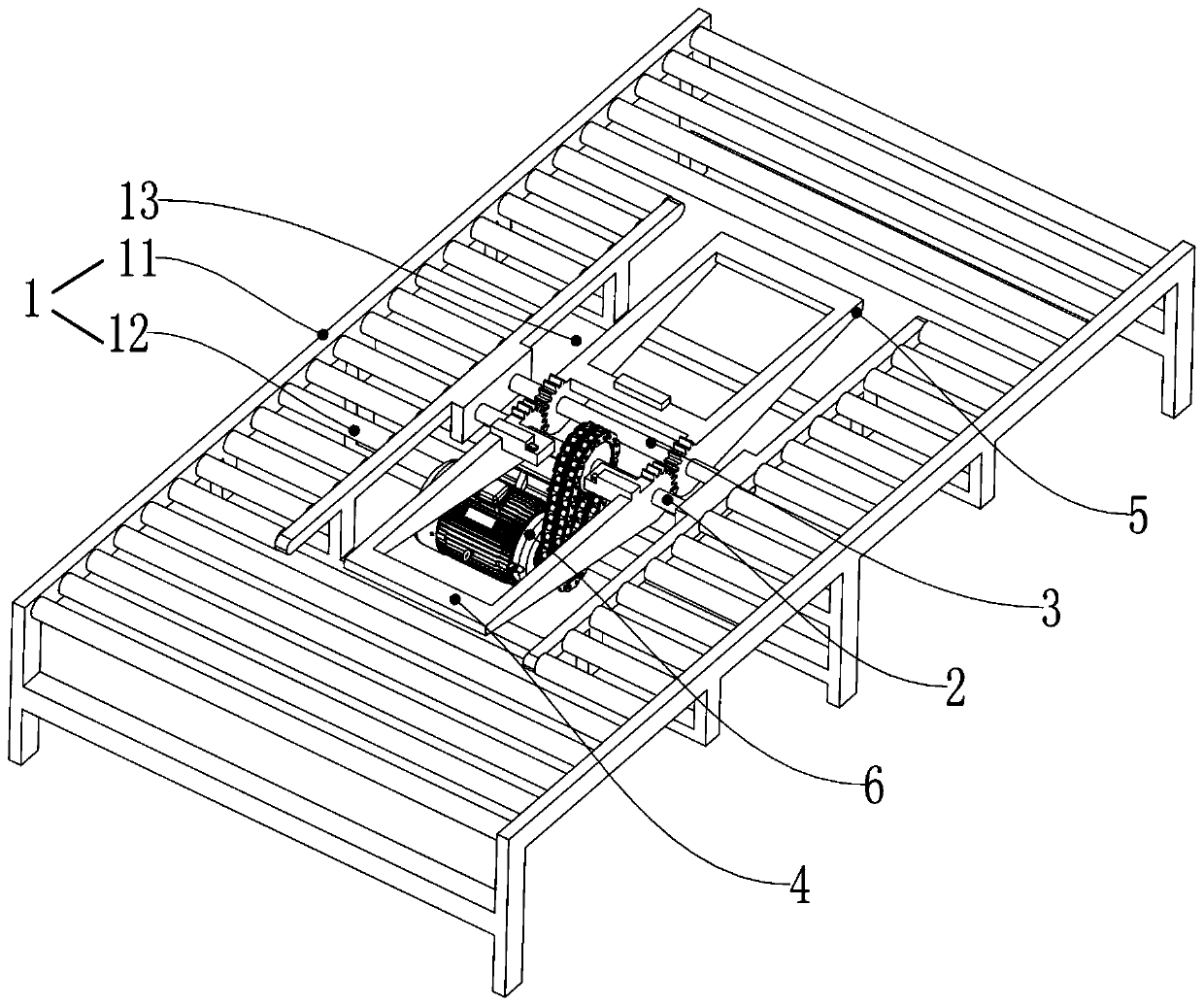

Board turnover device

A technology for turning over devices and plates, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of increasing production costs, time-consuming and labor-intensive, unfavorable continuous production, etc., and achieve the effect of improving production efficiency and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

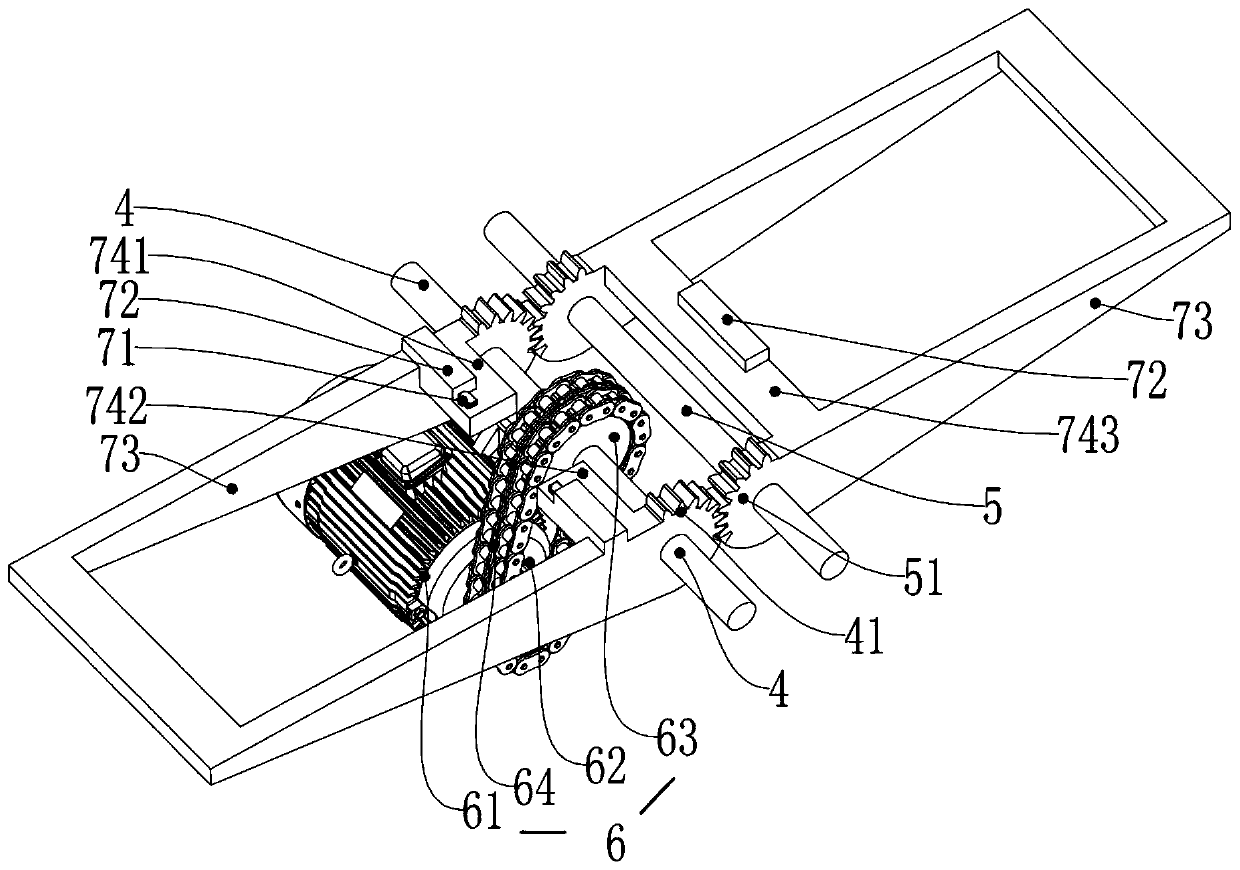

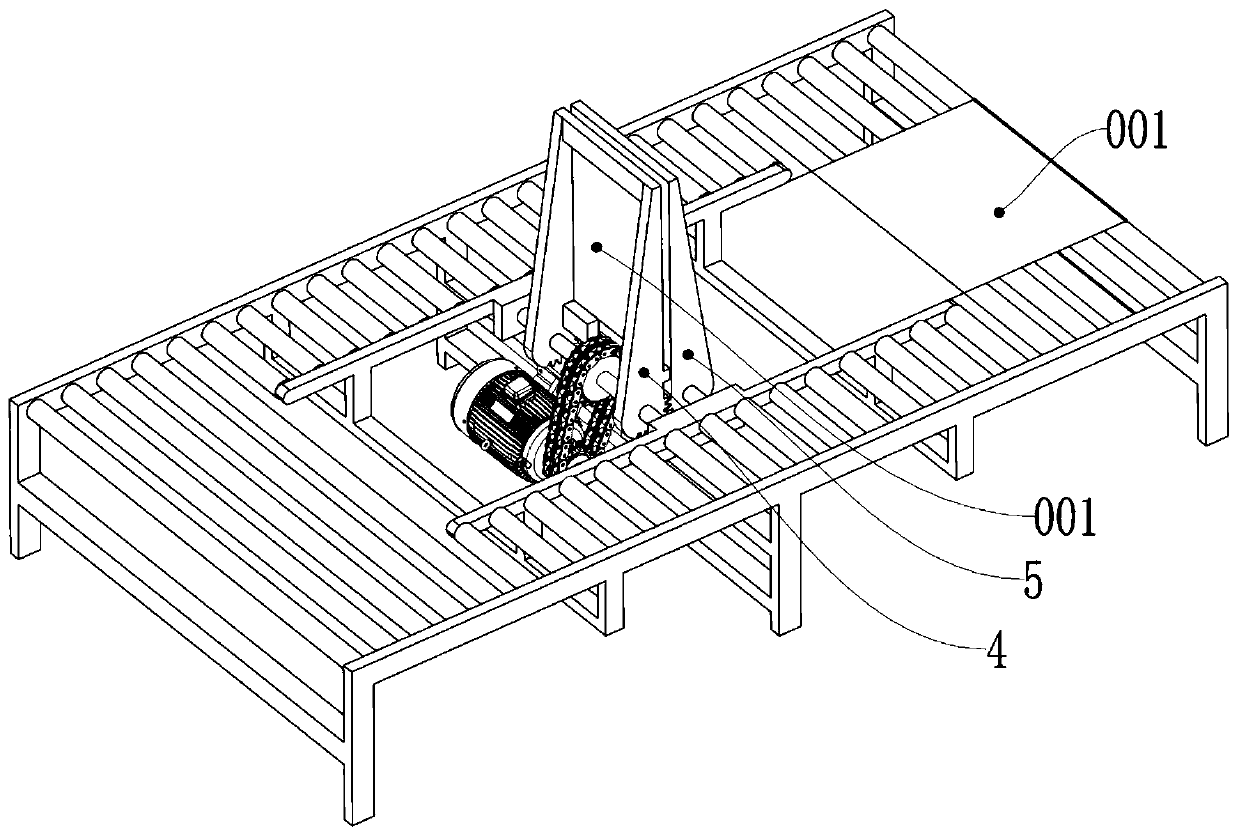

[0051] Embodiment 1 (flip 90 degrees):

[0052] Such as Figure 5 , in the initial state, the plate is sent to the active turning part 4 (it can also be the driven turning part 5); as shown in the figure, the line between the active turning part 4 and the driven turning part 5 is the central axis 01; by controlling the driving gear 41 Consistent with the physical parameters of the driven gear 51 (such as physical parameters such as size, tooth structure size, tooth structure number, etc.), to adjust the active turning member 4 and the driven turning member 5 to reach the central axis 01 at the same time; start the turning drive assembly 6. Make the output end of the overturning drive assembly 6 rotate clockwise, since the active overturning part 4 and the driven overturning part 5 reach the central axis 01 at the same time, as Figure 6 , the active turning part 4 and the driven turning part 5 clamp the plate, realizing the effect of turning the plate 90 degrees, and the front ...

Embodiment 2

[0053] Embodiment 2 (flip 180 degrees):

[0054] Such as Figure 5 , in the initial state, the plate is sent to the active turning part 4 (also can be the driven turning part 5); the line between the active turning part 4 and the driven turning part 5 is the central axis 01; by controlling the driving gear 41 and the driven The physical parameters of the gear 51 are different (such as physical parameters such as size, toothed structure size, toothed structure number), so as to adjust the active turning part 4 to reach the central axis 01 at first; The output end rotates clockwise, driving the active turning part 4 to turn clockwise, and the driven turning part 5 to turn counterclockwise, such as Figure 7 , because the driving active turning part 4 first passes through the central axis 01 and exceeds the central axis 01, the driving active turning part 4 presses the plate to the driven turning part 5, and the active turning part 4 and the driven turning part 5 clamp the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com