A sheet turning machine

A technology of turning machine and plate, applied in the field of plate processing, can solve problems such as bulky volume and complex structure, and achieve the effects of reducing labor intensity, improving production efficiency, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

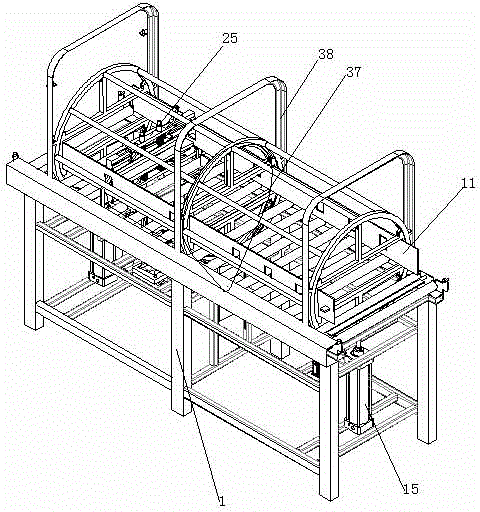

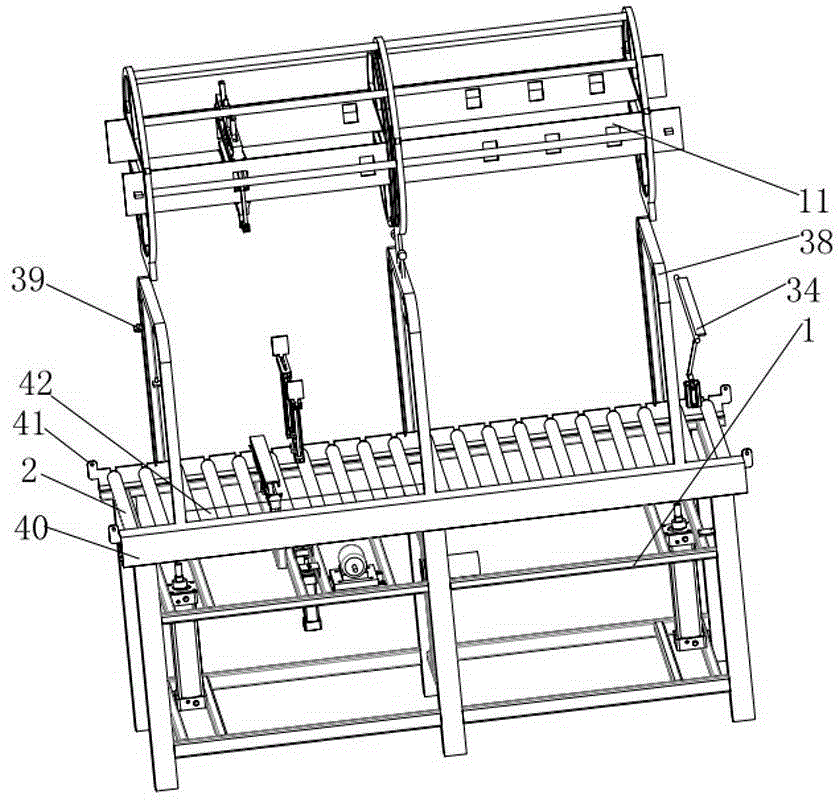

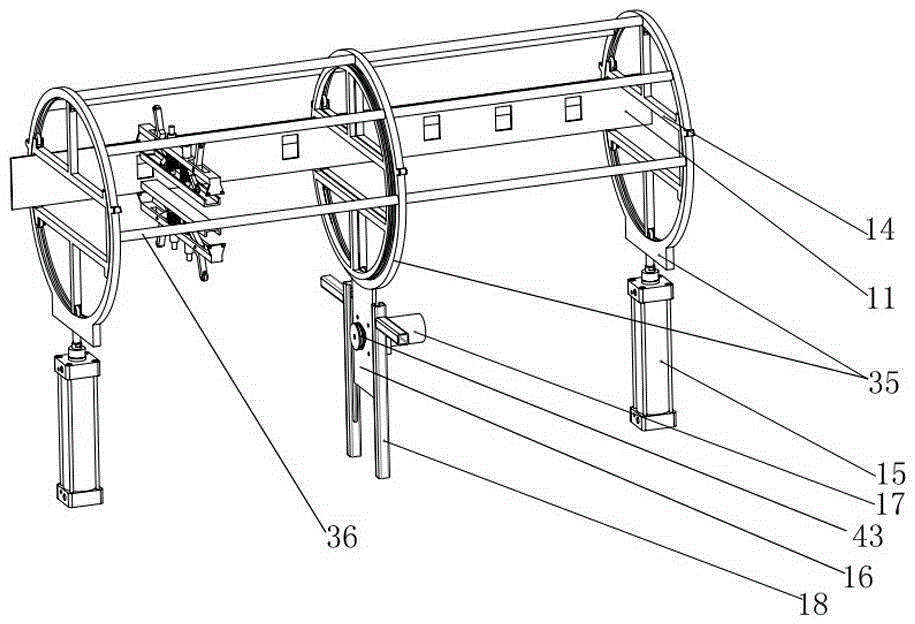

[0030] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 As shown, a plate turning machine includes a frame 1, a cylinder 15 arranged below the frame, a roller 2 arranged on the frame, a plate transverse tightening device is arranged between the frame and the rollers, and a horizontal tightening device is arranged above the rollers. There is a plate turning device and a plate turning mechanism, and the plate turning device includes a plate roller mechanism and a plate longitudinal clamping mechanism;

[0031] The plate roller mechanism includes a side plate 11, a plate longitudinal clamping mechanism is arranged between the two side plates, three overturning rollers 14 are arranged on the two side plates, and a rotating cam 12 is arranged on the overturning rollers. A belt pulley a13 is arranged on the rotating cam, and a roller guide rail 35 is arranged along the outer circumference of the rotating cam, and the cylinder 15 which can pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com