Infrared reflection polyolefin film and preparation method and application thereof

A technology of infrared reflection and infrared reflection pigments, which is applied in the fields of chemical instruments and methods, lamination, photovoltaic power generation, etc., can solve the problems that polyolefin films cannot reflect, achieve excellent UV resistance and water vapor barrier performance, ensure reflectivity, Effect of High Water Vapor Barrier Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

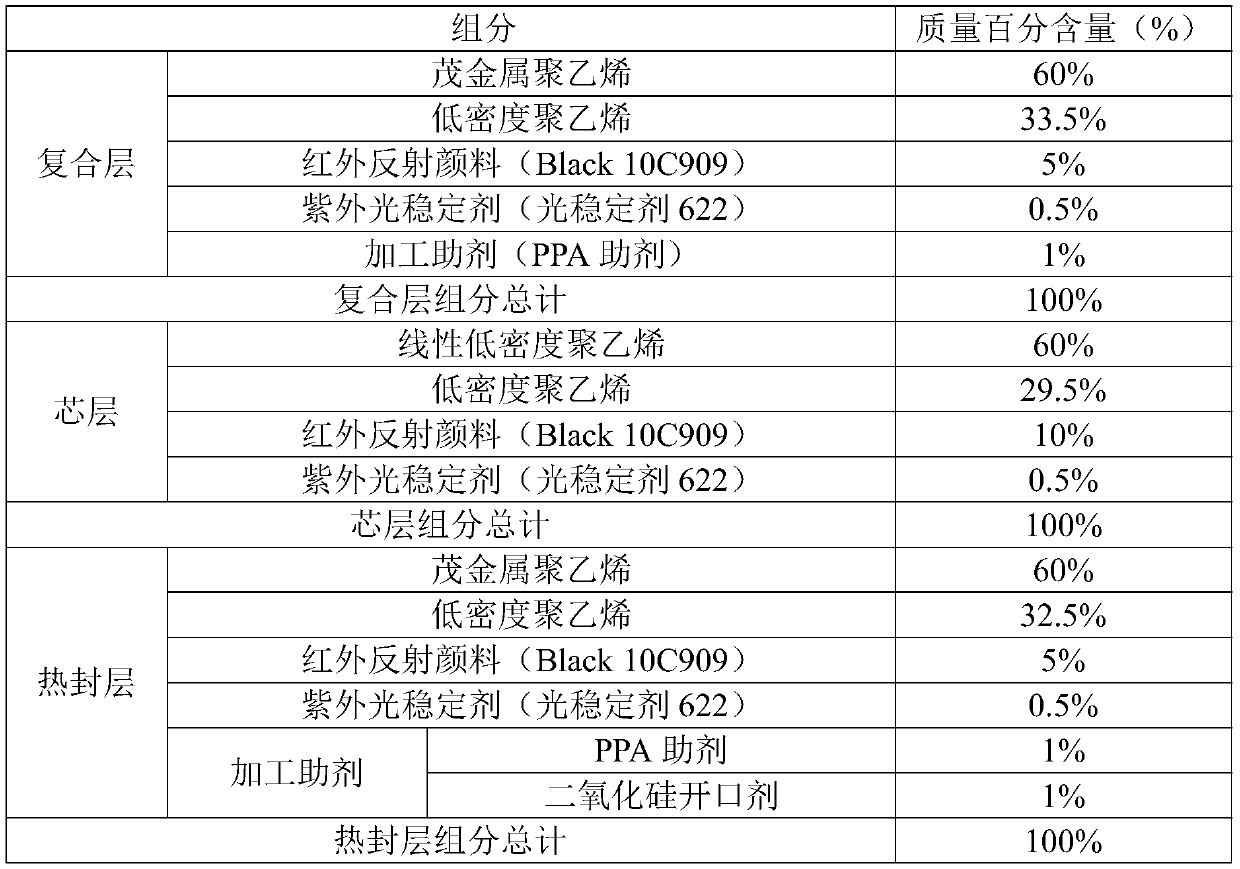

[0068] This embodiment provides an infrared reflective polyolefin film. The infrared reflective polyolefin film includes a composite layer, a core layer and a heat-sealing layer laminated in sequence. The thickness of the polyolefin film is 70 μm, the thickness of the composite layer is 20 μm, and the core layer The thickness is 30 μm, and the thickness of the heat-sealing layer is 20 μm. The raw materials for each layer include the following ingredients:

[0069]

[0070] The preparation method of the infrared reflective polyolefin film provided in this embodiment comprises the following steps:

[0071] (1) Put the preparation raw materials of the composite layer, the core layer and the heat-sealing layer into a high-speed mixer and mix them evenly, and then carry out blending modification and granulation at 180° C. through a twin-screw extruder to obtain a composite Layer composite particles, core layer composite particles and heat-sealing layer composite particles;

[0...

Embodiment 2

[0075] This embodiment provides an infrared reflective polyolefin film. The infrared reflective polyolefin film includes a composite layer, a core layer and a heat-sealing layer laminated in sequence. The thickness of the polyolefin film is 60 μm, the thickness of the composite layer is 15 μm, and the core layer The thickness is 30 μm, and the thickness of the heat-sealing layer is 15 μm. The raw materials for each layer include the following ingredients:

[0076]

[0077]

[0078] The preparation method of the infrared reflective polyolefin film provided in this embodiment comprises the following steps:

[0079] (1) Put the preparation raw materials of the composite layer, the core layer and the heat-sealing layer into a high-speed mixer and mix them uniformly, and then carry out blending modification and granulation at 200° C. through a twin-screw extruder to obtain Composite layer compound particles, core layer compound particles and heat-sealing layer compound partic...

Embodiment 3

[0083] This embodiment provides an infrared reflective polyolefin film. The infrared reflective polyolefin film includes a composite layer, a core layer and a heat-sealing layer laminated in sequence. The thickness of the polyolefin film is 100 μm, the thickness of the composite layer is 25 μm, and the core layer The thickness is 50 μm, and the thickness of the heat-sealing layer is 25 μm. The raw materials for each layer include the following ingredients:

[0084]

[0085] The preparation method of the infrared reflective polyolefin film provided in this embodiment comprises the following steps:

[0086] (1) Put the raw materials for the preparation of the composite layer, core layer and heat-sealing layer into a high-speed mixer and mix them uniformly, and then carry out blending modification and granulation at 250° C. through a twin-screw extruder to obtain a composite layer Compound particles, core layer compound particles and heat-sealing layer compound particles;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com